Abstract

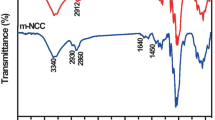

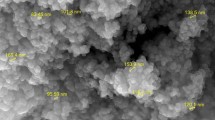

To prepare liquid silicone rubber (LSR)/cellulose nanocrystal (CNC) nanocomposite, 3-aminopropyltriethoxysilane (APTES) was used to modify the surface of CNC to improve the interfacial interaction between the hydrophilic CNC and the hydrophobic LSR. Fourier transform infrared spectroscopy and energy dispersive spectrometer results demonstrated that APTES modified CNC successfully. It was found that small amount of modified CNC (M-CNC) had better reinforcement than SiO2 in LSR nanocomposites, the tensile strength and the strain at break of LSR increased over 85% and 44% by adding 1.5 wt% M-CNC. However, DSC and rheology tests indicated that APTES modified CNC increased the curing temperature of LSR and limited the addition of CNC, which was attributed to poisoning of Pt catalyst by APTES. Furthermore, small amount of M-CNC improved the thermal stability of LSR, the TGA results showed that the 10% weight loss temperature (T10%) of LSR increased 56 °C with 1.0 wt% addition of M-CNC.

Similar content being viewed by others

References

Anzlovar A, Huskic M, Zagar E (2016) Modification of nanocrystalline cellulose for application as a reinforcing nanofiller in PMMA composites. Cellulose 23:505–518

Araki J, Wada M, Kuga S, Okana T (1999) Influence of surface charge on viscosity behavior of cellulose microcrystal suspension. J Wood Sci 45:258–261

Arrieta MP, Fortunati E, Dominici F, Lopez J, Kenny JM (2015) Bionanocomposite films based on plasticized PLA-PHB/cellulose nanocrystal blends. Carbohydr Polym 121:265–275

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromol 6:1048–1054

Ben Elmabrouk A, Thielemans W, Dufresne A, Boufi S (2009) Preparation of poly(styrene-co-hexylacrylate)/cellulose whiskers nanocomposites via miniemulsion polymerization. J Appl Polym Sci 114:2946–2955

de Menezes AJ, Siqueira G, Curvelo AAS, Dufresne A (2009) Extrusion and characterization of functionalized cellulose whiskers reinforced polyethylene nanocomposites. Polymer 50:4552–4563

Delebecq E, Ganachaud F (2012) Looking over liquid silicone rubbers: (1) network topology vs chemical formulations. ACS Appl Mater Interfaces 4:3340–3352

Delebecq E, Hamdani-Devarennes S, Raeke J, Lopez Cuesta J-M, Ganachaud F (2011) High residue contents indebted by platinum and silica synergistic action during the pyrolysis of silicone formulations. ACS Appl Mater Interfaces 3:869–880

Dubief D, Samain E, Dufresne A (1999) Polysaccharide microcrystals reinforced amorphous poly(beta-hydroxyoctanoate) nanocomposite materials. Macromolecules 32:5765–5771

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7:303–315

Emami Z, Meng QK, Pircheraghi G, Manas-Zloczower I (2015) Use of surfactants in cellulose nanowhisker/epoxy nanocomposites: effect on filler dispersion and system properties. Cellulose 22:3161–3176

Favier V, Canova GR, Cavaillé JY, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

Frone AN, Berlioz S, Chailan JF, Panaitescu DM, Donescu D (2011) Cellulose fiber-reinforced polylactic acid. Polym Compos 32:976–985

Gousse C, Chanzy H, Excoffier G, Soubeyrand L, Fleury E (2002) Stable suspensions of partially silylated cellulose whiskers dispersed in organic solvents. Polymer 43:2645–2651

Habibi Y (2014) Key advances in the chemical modification of nanocelluloses. Chem Soc Rev 43:1519–1542

Harkous A, Colomines G, Leroy E, Mousseau P, Deterre R (2016) The kinetic behavior of liquid silicone rubber: a comparison between thermal and rheological approaches based on gel point determination. React Funct Polym 101:20–27

Hassanabadi HM, Alemdar A, Rodrigue D (2015) Polypropylene reinforced with nanocrystalline cellulose: Coupling agent optimization. J Appl Polym Sci 132:42438

Hoeng F, Denneulin A, Bras J (2016) Use of nanocellulose in printed electronics: a review. Nanoscale 8:13131–13154

Lewis LN, Stein J, Gao Y, Colborn RE, Hutchins G (1997) Platinum catalysts used in the silicones industry. Their synthesis and activity in hydrosilylation. Platin Met Rev 41:66–75

Mariano M, El Kissi N, Dufresne A (2016) Cellulose nanocrystal reinforced oxidized natural rubber nanocomposites. Carbohydr Polym 137:174–183

Mariot D, Caro-Bretelle AS, Ienny P, Ganachaud F (2015) Influence of the grafting topology of hydrophobic silica surfaces on the mechanical properties of silicone high consistency rubbers. Polym Int 64:1128–1134

Muka I, Huba A (2008) The comparison of solid silicone rubber types manufactured by diverse technologies. Mater Sci Forum 589:123–129

Oksman K et al (2016) Review of the recent developments in cellulose nanocomposite processing. Compos A Appl Sci Manuf 83:2–18

Pei A, Zhou Q, Berglund LA (2010) Functionalized cellulose nanocrystals as biobased nucleation agents in poly(L-lactide) (PLLA)—crystallization and mechanical property effects. Compos Sci Technol 70:815–821

Salmieri S et al (2014) Antimicrobial nanocomposite films made of poly(lactic acid)-cellulose nanocrystals (PLA-CNC) in food applications: part A-effect of nisin release on the inactivation of Listeria monocytogenes in ham. Cellulose 21:1837–1850

Wu Q, Meng Y, Concha K, Wang S, Li Y, Ma L, Fu S (2013) Influence of temperature and humidity on nano-mechanical properties of cellulose nanocrystal films made from switchgrass and cotton. Ind Crop Prod 48:28–35

Wu G, Chen J, Huo S, Liu G, Kong Z (2014a) Thermoset nanocomposites from two-component waterborne polyurethanes and cellulose whiskers. Carbohydr Polym 105:207–213

Wu Q, Meng Y, Wang S, Li Y, Fu S, Ma L, Harper D (2014b) Rheological Behavior of Cellulose Nanocrystal Suspension: Influence of Concentration and Aspect Ratio. J Appl Polym Sci 131:40525

Wu Q, Li X, Fu S, Li Q, Wang S (2017) Estimation of aspect ratio of cellulose nanocrystals by viscosity measurement: influence of surface charge density and NaCl concentration. Cellulose 24:3255–3264

Xu P, Wang XX, Hu YD, Ding YS (2016) Piezoresistive properties of nanocomposites based on silicone rubber and ionic liquid-functionalized carbon black. Mater Lett 182:218–222

Zhao X, Zang C, Wen Y, Jiao Q (2015) Thermal and mechanical properties of liquid silicone rubber composites filled with functionalized graphene oxide. J Appl Polym Sci 132:42582

Zhu X, Zhang J (2013) The fundamentals of organosilicon material. Chemical Industry Press, Beijing

Zhu M et al (2016) Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 26:332–339

Acknowledgments

This work was financially supported by the Special Fund for Forest Scientific Research in the Public Welfare (201504603), the Program for key Science and Technology Team of Zhejiang Province (2013TD17), the Project of National Natural Science Foundation of China (21404092), Science and technology innovation program for college students of Zhejiang Province (2016R412040), the Project of National Natural Science Foundation of China (51603189) and Zhejiang Provincial Natural Science Foundation of China (No. LQ14C160004).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, X., Wu, Q., Zheng, M. et al. Mechanical, thermal properties and curing kinetics of liquid silicone rubber filled with cellulose nanocrystal. Cellulose 25, 473–483 (2018). https://doi.org/10.1007/s10570-017-1581-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1581-6