Abstract

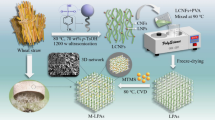

Cellulose nanocrystals (CNCs) with amphiphilic features were used in oil drop stabilization in diesel oil-in-water (o/w) emulsion. The functionalized CNCs were synthesized from a lignin-rich reject cellulose source from the pulp and paper industry, i.e., the non-bleached fines fractions of carton pulp. Partial periodate-chlorite oxidation, which was followed by reductive butylamination, was used to obtain surface-modified amphiphilic CNCs. All studied CNCs prevented droplet coalescence by stabilizing oil droplets in the emulsion thus resulting in stable o/w Pickering-like emulsions. CNCs from the fines fractions at concentrations 0.05–0.1% (weight by weight, w/w) provided high stability against creaming (i.e., phase separation), and they did not de-emulsify at low temperatures since the oil droplet size remained small at + 5 °C at a 0.05% (w/w) CNC concentration. Salinity improved the stability against creaming with the reference chemical pulp CNC, but negatively affected the emulsion creaming rate for CNCs that had a higher level of lignin. However, the non-bleached fines fraction of the pulp may provide one potential and cost-effective raw material source for the development of a novel bio-based chemical.

Similar content being viewed by others

References

Al-Majed AA, Adebayo AR, Hossain ME (2012) A sustainable approach to controlling oil spills. J Environ Manag 113:213–227. https://doi.org/10.1016/j.jenvman.2012.07.034

Chevalier Y, Bolzinger M-A (2013) Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf Physicochem Eng Asp 439:23–34. https://doi.org/10.1016/j.colsurfa.2013.02.054

Daza EA, Misra SK, Scott J et al (2017) Multi-shell nano-carboscavengers for petroleum spill remediation. Sci Rep 7:41880. https://doi.org/10.1038/srep41880

du Noüy PL (1925) An interfacial tensiometer for universal use. J Gen Physiol 7:625–633. https://doi.org/10.1085/jgp.7.5.625

Ek M, Gellerstedt G, Henriksson G (eds) (2009) Pulping chemistry and technology. In: Pulp and paper chemistry and technology. De Gruyter, Berlin

García A, Gandini A, Labidi J et al (2016) Industrial and crop wastes: a new source for nanocellulose biorefinery. Ind Crops Prod 93:26–38. https://doi.org/10.1016/j.indcrop.2016.06.004

George-Ares A, Clark JR (2000) Aquatic toxicity of two Corexit® dispersants. Chemosphere 40:897–906. https://doi.org/10.1016/S0045-6535(99)00498-1

Gharehkhani S, Sadeghinezhad E, Kazi SN et al (2015) Basic effects of pulp refining on fiber properties—a review. Carbohydr Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

Gosselink RJA, van Dam JEG, de Jong E et al (2011) Effect of periodate on lignin for wood adhesive application. Holzforschung. https://doi.org/10.1515/hf.2011.025

Guodong Q, Yupeng Z, Xuhe R, Jie C (2015) Research on development and effectiveness evaluation technology of new environment-friendly oil spill dispersant. Aquat Procedia 3:245–253. https://doi.org/10.1016/j.aqpro.2015.02.218

Hu Z, Ballinger S, Pelton R, Cranston ED (2015a) Surfactant-enhanced cellulose nanocrystal Pickering emulsions. J Colloid Interface Sci 439:139–148. https://doi.org/10.1016/j.jcis.2014.10.034

Hu Z, Patten T, Pelton R, Cranston ED (2015b) Synergistic stabilization of emulsions and emulsion gels with water-soluble polymers and cellulose nanocrystals. ACS Sustain Chem Eng 3:1023–1031. https://doi.org/10.1021/acssuschemeng.5b00194

Jiang Y, Liu X, Chen Y et al (2014) Pickering emulsion stabilized by lipase-containing periodic mesoporous organosilica particles: a robust biocatalyst system for biodiesel production. Bioresour Technol 153:278–283. https://doi.org/10.1016/j.biortech.2013.12.001

Kalashnikova I, Bizot H, Cathala B, Capron I (2011) New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir ACS J Surf Colloids 27:7471–7479. https://doi.org/10.1021/la200971f

Kalashnikova I, Bizot H, Bertoncini P et al (2013) Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 9:952–959. https://doi.org/10.1039/C2SM26472B

Katz S, Beatson RP, Scallan AM (1984) The determination of strong and weak acidic groups in sulfite pulps. Sven Papperstidning 65:48–53

Kester DR, Duedall IW, Connors DN, Pytkowicz RM (1967) Preparation of artificial seawater. Limnol Oceanogr 12:176–179. https://doi.org/10.4319/lo.1967.12.1.0176

Koskenhely K (2008) Refining of chemical pulp fibers. In: Paulapuro H (ed) Papermaking part 1, stock preparation and wet end. Finnish Paper Engineers’ Association. Espoo, Finland

Nyankson E, DeCuir MJ, Gupta RB (2015) Soybean lecithin as a dispersant for crude oil spills. ACS Sustain Chem Eng 3:920–931. https://doi.org/10.1021/acssuschemeng.5b00027

Ojala J, Sirviö JA, Liimatainen H (2016) Nanoparticle emulsifiers based on bifunctionalized cellulose nanocrystals as marine diesel oil–water emulsion stabilizers. Chem Eng J 288:312–320. https://doi.org/10.1016/j.cej.2015.10.113

Orelma H, Tanaka A, Rautkoski H et al (2017) Mechanically ground softwood fines as a raw material for cellulosic applications. Cellulose 24:3869–3882. https://doi.org/10.1007/s10570-017-1403-x

Pi G, Li Y, Bao M et al (2016) Novel and environmentally friendly oil spill dispersant based on the synergy of biopolymer xanthan gum and silica nanoparticles. ACS Sustain Chem Eng 4:3095–3102. https://doi.org/10.1021/acssuschemeng.6b00063

Prince RC (2015) Oil spill dispersants: Boon or bane? Environ Sci Technol 49:6376–6384. https://doi.org/10.1021/acs.est.5b00961

Rattaz A, Mishra SP, Chabot B, Daneault C (2011) Cellulose nanofibres by sonocatalysed-TEMPO-oxidation. Cellulose 18:585–593. https://doi.org/10.1007/s10570-011-9529-8

Saha A, Nikova A, Venkataraman P et al (2013) Oil emulsification using surface-tunable carbon black particles. ACS Appl Mater Interfaces 5:3094–3100. https://doi.org/10.1021/am3032844

Silva MC, Lopes OR, Colodette JL et al (2008) Characterization of three non-product materials from a bleached eucalyptus kraft pulp mill, in view of valorising them as a source of cellulose fibres. Ind Crops Prod 27:288–295. https://doi.org/10.1016/j.indcrop.2007.11.005

Sirvio J, Hyvakko U, Liimatainen H et al (2011) Periodate oxidation of cellulose at elevated temperatures using metal salts as cellulose activators. Carbohydr Polym 83:1293–1297. https://doi.org/10.1016/j.carbpol.2010.09.036

Tadros TF (ed) (2013) Emulsion formation and stability. Wiley-VCH, Weinheim

Wang W, Zheng Y, Lee K (2013) Chemical dispersion of oil with mineral fines in a low temperature environment. Mar Pollut Bull 72:205–212. https://doi.org/10.1016/j.marpolbul.2013.03.042

Xhanari K, Syverud K, Stenius P (2011) Emulsions stabilized by microfibrillated cellulose: the effect of hydrophobization, concentration and O/W ratio. J Dispers Sci Technol 32:447–452. https://doi.org/10.1080/01932691003658942

Yu G, Dong J, Foster LM et al (2014) Breakup of oil jets into droplets in seawater with environmentally benign nanoparticle and surfactant dispersants. Ind Eng Chem Res. https://doi.org/10.1021/ie503658h

Zeinstra-Helfrich M, Koops W, Murk AJ (2015) The NET effect of dispersants—a critical review of testing and modelling of surface oil dispersion. Mar Pollut Bull 100:102–111. https://doi.org/10.1016/j.marpolbul.2015.09.022

Zhang Y, Chen D, Ennis AC et al (2013) Chemical dispersant potentiates crude oil impacts on growth, reproduction, and gene expression in Caenorhabditis elegans. Arch Toxicol 87:371–382. https://doi.org/10.1007/s00204-012-0936-x

Acknowledgments

This study was funded by the Academy of Finland (283187). The support of the Ahti Pekkala Foundation and the Tiina and Antti Herlin Foundation is gratefully acknowledged. The contribution of Mr. Mikael Karjalainen in the raw material characterization and the experience of Dr. Ilkka Miinalainen in TEM measurements are also much appreciated. We thank Neste Oyj Finland for providing the marine diesel oil sample for the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ojala, J., Sirviö, J.A. & Liimatainen, H. Preparation of cellulose nanocrystals from lignin-rich reject material for oil emulsification in an aqueous environment. Cellulose 25, 293–304 (2018). https://doi.org/10.1007/s10570-017-1568-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1568-3