Abstract

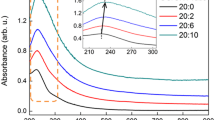

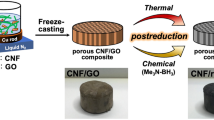

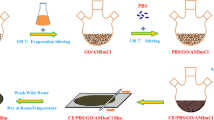

Cellulose hybrid fibers (CeHFs), hybridized via graphene oxide (GO) and metal ions (Ca2+), are synthesized by dry-jet wet spinning. The synthesized GO–Ca2+-CeHFs exhibit the tensile strength and the breaking elongation of 551 ± 37.5 MPa and 5.9 ± 0.4%, respectively, while the GO/cellulose composite fibers (GO–CeFs) show the tensile strength of 403 ± 76.0 MPa and the elongation of 4.5 ± 0.5%; thus, the GO–Ca2+–CeHFs demonstrate improved mechanical properties over GO–CeFs by 37 and 31% in terms of tensile strength and elongation, respectively. These results are attributed to the metal ions that form a good interfacial interaction between the functional groups of cellulose and GO. In addition, the tensile strength of GO–Ba2+–CeHFs is as high as 580 ± 25 MPa, which is induced by the difference in the ionic radius. Therefore, the high mechanical properties of the synthesized cellulose-based fibers have the potential to be used as sustainable alternative to the synthetic fibers used in the industrial applications.

Similar content being viewed by others

References

ASTM D1577-07 (2012) Standard Test Methods for Linear Density of Textile Fibers. ASTM International, West Conshohocken. https://doi.org/10.1520/D1577-07R12

Belgacem MN, Czeremuszkin G, Sapieha S (1995) Surface characterization of cellulose fibres by XPS and inverse gas chromatography. Cellulose 2:145–157

Chao SH, Suzuki Y, Zysk JR, Cheung WY (1984) Activation of calmodulin by various metal cations as a function of ionic radius. Mol Pharmacol 26:75–82

Charleux B, Coperet C, Lacote E (2015) Chemistry of organo-hybrids: synthesis and characterization of functional nano-objects. Willey, New York

Chen L, Xu Z, Li J, Zhou B, Shan M, Li Y, Liu L, Li B, Niu J (2014) Modifying graphite oxide nanostructures in various media by high-energy irradiation. RSC Adv 4:1025–1031

Domun N, Hadavinia H, Zhang T, Sainsbury T, Liaghat GH, Vahid S (2015) Improving the fracture toughness and the strength of epoxy using nanomaterials—a review of the current status. Nanoscale 7:10294–10329

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39:228–240

Faur-Brasquet C, Reddad Z, Kadirvelu K, Cloirec PL (2002) Modeling the adsorption of metal ions (Cu2 + , Ni2 + , Pb2 +) onto ACCs using surface complexation models. Appl Surf Sci 196:356–365

Feng Y, Zhang X, Shen Y, Yoshino K, Feng W (2012) A mechanically strong, flexible and conductive film based on bacterial cellulose/graphene nanocomposite. Carbohydr Polym 87:644–649

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Huang FY, Wu XJ, Yu Y, Lu YH (2015) Preparation and properties of cellulose laurate (CL)/starch nanocrystals acetate (SNA) bio-nanocomposites. Polymers 7:1331–1345

Hummers WS Jr, Offerman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Kramar AD, Žekić AA, Obradović BM, Kuraica MM, Kostić MM (2014) Study of interaction between nitrogen DBD plasma-treated viscose fibers and divalent ions Ca2+ and Cu2+. Cellulose 21:3279–3289

Kudin KN, Ozbas B, Schniepp HC, Prud’homme RK, Aksay IA, Car R (2008) Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett 8:36–41

Lee SH, Wang S (2006) Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos A 37:80–91

Li W, Dichiara A, Bai J (2013) Carbon nanotube-graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos Sci Technol 74:221–227

Li Y, Zhu H, Zhu S, Wan J, Liu Z, Vaaland O, Lacey S, Fang Z, Dai H, Li T, Hu L (2015) Hybridizing wood cellulose and graphene oxide toward high-performance fibers. NPG Asia Mater 7:e150

Liu LH, Métivier R, Wang S, Wang S (2012) Advanced nanohybrid materials: surface modification and applications. J Nanometer 2012:1–2

Martell E, Hancock RD (1996) Metal complexes in aqueous solutions. Plenum Press, New York

Matos GD, Arruda MAZ (2003) Vermicompost as natural adsorbent for removing metal ions from laboratory effluents. Process Biochem 39:81–88

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibres, biodegradable polymers and biocomposites: an overview. Macromol Mater Eng 276–277:1–24

Okieimen FE, Ogbeifun DE, Nwala GN, Kumsah CA (1985) Binding of cadmium, copper, and lead ions by modified cellulosic materials. Bull Environ Contam Toxicol 34:866–870

Öztürk HB, Manh JV, Bechtold T (2009) Interaction of cellulose with alkali metal ions and complexed heavy metals. Lenzing Ber 87:142–150

Park S, Lee KS, Bozoklu G, Cai W, Nguyen ST, Ruoff RS (2008) Graphene oxide papers modified by divalent ions-enhancing mechanical properties via chemical cross-linking. ACS Nano 2:572–578

Shi H, Li W, Zhong L, Xu C (2014) Methylene blue adsorption from aqueous solution by magnetic cellulose/graphene oxide composite: equilibrium, kinetics, and thermodynamics. Ind Eng Chem Res 53:1108–1118

Shimada K, Fujikawa K, Yahara K, Nakamura T (1992) Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem 40:945–948

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Stankovich S, Dikin DA, Dommett GHB, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Nguyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442:282–286

Terzopoulou Z, Kyzas GZ, Bikiaris DN (2015) Recent advances in nanocomposite materials of graphene derivatives with polysaccharides. Materials 8(2):652–683

Tian M, Qu L, Zhang X, Zhang K, Zhu S, Guo X, Han G, Tang X, Sun Y (2014) Enhanced mechanical and thermal properties of regenerated cellulose/graphene composite fibers. Carbohydr Polym 111:456–462

Unterweger C, Brüggermann O, Fürst C (2014) Synthetic fibers and thermoplastic short-fiber-reinforced polymers: properties and characterization. Polym Compos 35:227–236

Wang JY, Yang SY, Huang YL, Tien HW, Chin WK, Ma CCM (2011) Preparation and properties of grpahene oxide/polyimide composite films with low dielectric constant and ultrahigh strength via in situpolymerization. J Mater Chem 21:13569–13575

Wang B, Lou W, Wang X, Hao J (2012) Relationship between dispersion state and reinforcement effect of graphene oxide in microcrystalline cellulose-graphene oxide composite films. J Mater Chem 22:12859–12866

Wang S, Jiang F, Xu X, Kuang Y, Fu K, Hitz E, Hu L (2017) Super-strong, super-stiff macrofibers with aligned, long bacterial cellulose nanofiber. Adv Mater 29:1702498

Wu T, Farnood R (2015) A preparation method of cellulose fiber networks reinforced by glutaraldehyde-treated chitosan. Cellulose 22:1955–1961

Xu Z, Sun H, Zhao X, Gao C (2013) Ultrastrong fibers assembled from giant graphene oxide sheets. Adv Mater 25:188–193

Yadav M, Rhee KY, Jung IH, Park SJ (2013) Eco-friendly synthesis, characterization and properties of a sodium carboxymethyl cellulose/graphene oxide nanocomposite film. Cellulose 20:687–698

Yang J, Chen S, Chen Y, Wang B, Pei Q, Wang H (2017) Macrofibers with high mechanical performance based on aligned bacterial cellulose nanofibers. ACS Appl Mater Interfaces 9:20330–20339

Zhao H, Kwak JH, Zhang ZC, Brown HM, Arey BW, Holladay JE (2007) Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohydr Polym 68:235–241

Zhbankov RG, Firsov SP, Buslov DK, Nikonenko NA, Marchewha MK, Ratajczak H (2002) Structural physico-chemistry of cellulose macromolecules. Vibrational spectra and structure of cellulose. J Mol Struct 614:117–125

Zhu Y, Murali S, Cai W, Li X, Suk JW, Potts JR, Ruoff RS (2010) Graphene and graphene oxide: synthesis, properties, and applications. Adv Mater 22:3906–3924

Acknowledgments

This research was supported by Nano·Material Technology Development Program through the National Research Foundation of Korea funded by the Ministry of Science, ICT and Future Planning (NRF-2016M3A7B4900135).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ryu, J., Lim, J.S., Ahn, S. et al. Structure and properties of graphene oxide/cellulose hybrid fibers via divalent metal ions treatment. Cellulose 25, 517–525 (2018). https://doi.org/10.1007/s10570-017-1535-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1535-z