Abstract

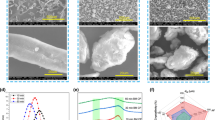

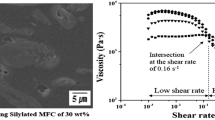

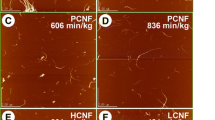

Microfibrillated cellulose (MFC)-reinforced polypropylene (PP) was prepared via two engineering approaches: disintegration of the pulp by a bead mill followed by a melt-compounding process with PP (B-MFC-reinforced PP); and disintegration of the pulp mixed with PP by a twin screw extruder followed by a melt-compounding process (T-MFC-reinforced PP). The effects that the engineering process and the microfibrillation of the pulp had upon the dispersion and mechanical properties were investigated through tensile tests, rheological analysis and X-ray computed tomography. The bead-milling method enabled a uniform microfibrillation of the pulp to under 100 nm, which corresponded to a surface area of 133–146 m2/g for the pulp, found by the Brunauer–Emmett–Teller (BET) analysis. The T-MFC-reinforced PP with 30 wt% MFC content exhibited a tensile modulus of 5.3 GPa and a strength of 85 MPa, whereas the B-MFC-reinforced PP composites with the same content of MFC exhibited values of 4.1 GPa and 59.6 MPa, respectively. Rheological analysis revealed that the complex viscosity and storage modulus at 170 °C of T-MFC-reinforced PP with 30 wt% MFC content are 5–7 and 5–8 times higher than that of B-MFC-reinforced PP, respectively. This indicated that T-MFC was more dispersed in the PP than B-MFC. Therefore, T-MFC produced a more rigid interconnected network in the matrix during the melting state than B-MFC.

Similar content being viewed by others

References

Abe K (2016) Nanofibrillation of dried pulp in NaOH solutions using bead milling. Cellulose 23(2):1–5. doi:10.1007/s10570-016-0891-4

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibres with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278. doi:10.1021/bm700624p

Agarwal UP, Sabo R, Reiner RS, Clemons CM, Rudie AW (2012) Spatially resolved characterization of cellulose nanocrystal—polypropylene composite by confocal raman microscopy. Appl Spectrosc 66(7):750–756. doi:10.1366/11-06563

Aitomäki Y, Oksman K (2014) Reinforcing efficiency of nanocellulose in polymers. React Funct Polym 85:151–156. doi:10.1016/j.reactfunctpolym.2014.08.010

Bagheriasl D, Carreau PJ, Riedl B (2015) Properties of polypropylene and polypropylene/poly(ethylene-co-vinyl alcohol) blend/CNC nanocomposites. Compos Sci Technol 117(29):357–363. doi:10.1016/j.compscitech.2015.07.012

Bagheriasl D, Carreau PJ, Riedl B, Dubois C, Hamad WY (2016) Shear rheology of polylactide (PLA)–cellulose nanocrystal (CNC) nanocomposites. Cellulose 23(3):1885–1897. doi:10.1007/s10570-016-0914-1

Bahar E, Ucar N, Onen A, Wang Y, Oksüz M, Ayaz O, Ucar M, Demir A (2012) Thermal and mechanical properties of polypropylene nanocomposite materials reinforced with cellulose nano whiskers. J Appl Polym Sci 125(4):2882–2889. doi:10.1002/app.36445

Ben Azouz K, Ramires EC, Van den Fonteyne W, El Kissi N, Dufresne A (2011) Simple method for the melt extrusion of a cellulose nanocrystal reinforced hydrophobic polymer. ACS Macro Lett 1(1):236–240. doi:10.1021/mz2001737

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13(2):171–180. doi:10.1007/s10570-006-9061-4

Brunauer S, Emmett PH, Edward Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60(2):309–319. doi:10.1021/ja01269a023

Cassagnau P (2013) Linear viscoelasticity and dynamics of suspensions and molten polymers filled with nanoparticles of different aspect ratios. Polymer 54(18):4762–4775. doi:10.1016/j.polymer.2013.06.012

Ching YC, Ali ME, Abdullah LC, Choo KW, Kuan YC, Julaihi SJ, Chuah CH, Liou NS (2016) Rheological properties of cellulose nanocrystal-embedded polymer composites: a review. Cellulose 23(2):1011–1030. doi:10.1007/s10570-016-0868-3

Cox HL (1952) The elasticity and strength of paper and other fibrous materials. Br J Appl Phys 3(3):72–79

Farahbakhsh N, Venditti RA, Jur JS (2014) Mechanical and thermal investigation of thermoplastic nanocomposite films fabricated using micro-and nano-sized fillers from recycled cotton T-shirts. Cellulose 21(4):2743–2755. doi:10.1007/s10570-014-0285-4

Favier V, Canova GR, Cavaillé JY, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6(5):351–355. doi:10.1002/pat.1995.220060514

Fu SY, Lauke B (1996) Effects of fiber length and fiber orientation distributions on the tensile strength of short-fiber-reinforced polymers. Compos Sci Technol 56(10):1179–1190. doi:10.1016/S0266-3538(96)00072-3

Goffin AL, Raquez JM, Duquesne E, Siqueira G, Habibi Y, Dufresne A, Dubois P (2011) Poly (ɛ-caprolactone) based nanocomposites reinforced by surface-grafted cellulose nanowhiskers via extrusion processing: morphology, rheology, and thermo-mechanical properties. Polymer 52(7):1532–1538. doi:10.1016/j.polymer.2011.02.004

Hassanabadi HM, Alemdar A, Rodrigue D (2015) Polypropylene reinforced with nanocrystalline cellulose: coupling agent optimization. J Appl Polym Sci 132(24):2882–2889. doi:10.1002/app.42438

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43(8):3434–3441. doi:10.1016/j.eurpolymj.2007.05.038

Hietala M, Mathew AP, Oksman K (2013) Bionanocomposites of thermoplastic starch and cellulose nanofibers manufactured using twin-screw extrusion. Eur Polym J 49(4):950–956. doi:10.1016/j.eurpolymj.2012.10.016

Ho TTT, Abe K, Zimmermann T, Yano H (2015) Nanofibrillation of pulp fibers by twin-screw extrusion. Cellulose 22(1):421–433. doi:10.1007/s10570-014-0518-6

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10(9):2571–2576. doi:10.1021/bm900520n

Iwamoto S, Yamamoto S, Lee SH, Endo T (2014) Mechanical properties of polypropylene composites reinforced by surface-coated microfibrillated cellulose. Compos Part A Appl Sci 59:26–29. doi:10.1016/j.compositesa.2013.12.011

Iwatake A, Nogi M, Yano H (2008) Cellulose nanofiber-reinforced polylactic acid. Compos Sci Technol 68(9):2103–2106. doi:10.1016/j.compscitech.2008.03.006

Jonoobi M, Harun J, Mathew AP, Oksman K (2010) Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos Sci Technol 70(12):1742–1747. doi:10.1016/j.compscitech.2010.07.00

Jonoobi M, Oladi R, Davoudpour Y, Oksman K, Dufresne A, Hamzeh Y, Davoodi R (2015) Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: a review. Cellulose 22(2):935–969. doi:10.1007/s10570-015-0551-0

Khalil HA, Bhat AH, Yusra AI (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979. doi:10.1016/j.carbpol.2011.08.078

Khoshkava V, Kamal MR (2014) Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl Mater Interfaces 6(11):8146–8157. doi:10.1021/am500577e

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature based materials. Angew Chem Int Ed 50(24):5438–5466. doi:10.1002/anie.201001273

Krenchel H (1964) Fibre reinforcement. Alademisk Forlag, Copenhagen

Lee KY, Aitomäki Y, Berglund LA, Oksman K, Bismarck A (2014) On the use of nanocellulose as reinforcement in polymer matrix composites. Compos Sci Technol 105:15–27. doi:10.1016/j.compscitech.2014.08.032

Lindström T, Aulin C (2014) Market and technical challenges and opportunities in the area of innovative new materials and composites based on nanocellulosics. Scand J Forest Res 29(4):345–351. doi:10.1080/02827581.2014.928365

Liu Y, Yu Z, Zhou S, Wu L (2006) De-agglomeration and dispersion of nano-TiO2 in an agitator bead mill. J Dispers Sci Technol 27(7):983–990. doi:10.1080/01932690600766975

Ljungberg N, Bonini C, Bortolussi F, Boisson C, Heux L, Cavaillé JY (2005) New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: effect of surface and dispersion characteristics. Biomacromolecules 6(5):2732–2739. doi:10.1021/bm050222v

Menezes AJ, Siqueira G, Curvelo AAS, Dufresne A (2009) Extrusion and characterization of functionalized cellulose whiskers reinforced polyethylene nanocomposites. Polymer 50(19):4552–4563. doi:10.1016/j.polymer.2009.07.038

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20(5):2221–2262. doi:10.1007/s10570-013-0007-3

Morandi G, Heath L, Thielemans W (2009) Cellulose nanocrystals grafted with polystyrene chains through surface-initiated atom transfer radical polymerization (SI-ATRP). Langmuir 25(14):8280–8286. doi:10.1021/la900452a

Nishino T, Matsuda I, Hirao K (2004) All-cellulose composite. Macromolecules 37(20):7683–7687. doi:10.1021/ma049300h

Oksman K, Aitomäki Y, Mathew AP, Siqueira G, Zhou Q, Butylina S, Tanpichai S, Zhou X, Hooshmand S (2016) Review of the recent developments in cellulose nanocomposite processing. Compos A 83:2–18. doi:10.1016/j.compositesa.2015.10.041

Olsson RT, Samir MA, Salazar-Alvarez G, Belova L, Ström V, Berglund LA, Ikkala O, Nogués J, Gedde UW (2010) Making flexible magnetic aerogels and stiff magnetic nanopaper using cellulose nanofibrils as templates. Nat Nanotechnol 5(8):584–588. doi:10.1038/nnano.2010.155

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941. doi:10.1021/bm061215p

Page DH, El-Hosseiny F (1983) The mechanical properties of single wood pulp fibres. J Pulp Pap Sci 9:99–100

Peng Y, Gallegos SA, Gardner DJ, Han Y, Cai Z (2014) Maleic anhydride polypropylene modified cellulose nanofibril polypropylene nanocomposites with enhanced impact strength. Polym Compos 37(3):782–793. doi:10.1002/pc.23235

Saito T, Kimura S, Nishiyama Y, Isogai Y (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491. doi:10.1021/bm0703970

Saito T, Kuramae R, Wohlert J, Berglund LA, Isogai A (2012) An ultrastrong nanofibrillar biomaterial: the strength of single cellulose nanofibrils revealed via sonication-induced fragmentation. Biomacromolecules 14(1):248–253. doi:10.1021/bm301674e

Sakurada I, Nukushina Y, Ito T (1962) Experimental determination of the elastic modulus of crystalline regions in oriented polymers. J Polym Sci 57(165):651–660

Sato A, Kabusaki D, Okumura H, Nakatani T, Nakatsubo F, Yano H (2016) Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos Part A 83:72–79. doi:10.1016/j.compositesa.2015.11.009

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794. doi:10.1177/004051755902901003

Sehaqui H, Zhou Q, Berglund LA (2011) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71(13):1593–1599. doi:10.1016/j.compscitech.2011.07.003

Semba T, Ito A, Kitagawa K, Nakatani T, Yano H, Sato A (2014) Thermoplastic composites of polyamide-12 reinforced by cellulose nanofibers with cationic surface modification. J Appl Polym Sci. doi:10.1002/app.40920

Suryanegara L, Nakagaito AN, Yano H (2009) The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos Sci Technol 69(7):1187–1192. doi:10.1016/j.compscitech.2009.02.022

Suzuki K, Okumura H, Kitagawa K, Sato S, Nakagaito AN, Yano H (2013) Development of continuous process enabling nanofibrillation of pulp and melt compounding. Cellulose 20(1):201–210. doi:10.1007/s10570-012-9843-9

Suzuki K, Sato A, Okumura H, Hashimoto T, Nakagaito AN, Yano H (2014) Novel high-strength, micro fibrillated cellulose-reinforced polypropylene composites using a cationic polymer as compatibilizer. Cellulose 21(1):507–518. doi:10.1007/s10570-013-0143-9

Suzuki K, Homma Y, Igarashi Y, Okumura H, Semba T, Nakatsubo H, Yano H (2016) Investigation of the mechanism and effectiveness of cationic polymer as a compatibilizer in microfibrillated cellulose-reinforced polyolefins. Cellulose 23(1):623–635. doi:10.1007/s10570-015-0845-2

Tanpichai S, Quero F, Nogi M, Yano H, Young RJ, Lindström T, Sampson WW, Eichhorn SJ (2012) Effective Young’s modulus of bacterial and microfibrillated cellulose fibrils in fibrous networks. Biomacromol 13(5):1340–1349. doi:10.1021/bm300042t

Tingaut P, Zimmermann T, Lopez-Suevos F (2009) Synthesis and characterization of bionanocomposites with tunable properties from poly (lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11(2):454–464. doi:10.1021/bm901186u

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Uetani K, Yano H (2010) Nanofibrillation of wood pulp using a high-speed blender. Biomacromolecules 12(2):348–353. doi:10.1007/s10570-012-9745-x

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24(3):784–795. doi:10.1021/la702481v

Wang Y, Forssberg E (2006) Production of carbonate and silica nano-particles in stirred bead milling. Int J Miner Process 81(1):1–14. doi:10.1016/j.minpro.2006.05.007

Acknowledgments

The authors thank Professor Humiaki Nakatsubo and Associate Professor Kentaro Abe of the Research Institute for Sustainable Humanosphere (RISH), Kyoto University, for helpful discussions. This study was supported by the New Energy and Industrial Technology Development Organization (NEDO), Japan; the Oji Holdings Corporation; Nippon Paper Industries Co., Ltd.; Mitsubishi Chemical, Corporation; the DIC Corporation and Sumitomo Rubber Industries, Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suzuki, K., Homma, Y., Igarashi, Y. et al. Effect of preparation process of microfibrillated cellulose-reinforced polypropylene upon dispersion and mechanical properties. Cellulose 24, 3789–3801 (2017). https://doi.org/10.1007/s10570-017-1355-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1355-1