Abstract

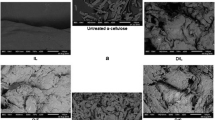

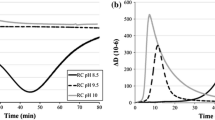

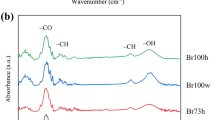

Carbonyl and carboxyl groups introduced by oxidative processes during production and purification of celluloses determine intra- and intermolecular interactions and thus application-related bulk and surface properties of cellulosic materials. We report a comprehensive approach to the quantification of carboxyl and carbonyl groups in cellulose films upon reconstitution from NMMO solutions. Measurements of the excess conductivity were combined with the determination of the molecular weight distribution, quantification of the carboxyl and carbonyl group content, crystallinity and film swelling in aqueous solutions. TEMPO-oxidized, NMMO-regenerated cellulose films were additionally analysed as a reference system for extensive cellulose oxidation. Our reported data demonstrate that dissolution of cellulose in NMMO results in the formation of onic acids, chain degradation, increased ionization and film swelling, whereas TEMPO-oxidation introduced carbonyl groups as well as onic and uronic acids causing a significantly increased charging, ion accumulation and swelling even at higher crystallinity.

Similar content being viewed by others

References

Abe Y, Mochizuki A (2003) Hemodialysis membrane prepared from cellulose/N-methylmorpholine-N-oxide solution. III. The relationship between the drying condition of the membrane and its permeation behavior. J Appl Polym Sci 89:1671–1681. doi:10.1002/app.12439

Adorjan I, Potthast A, Rosenau T, Sixta H, Kosma P (2005) Discoloration of cellulose solutions in N-methylmorpholine-N-oxide (Lyocell). Part 1: studies on model compounds and pulps. Cellulose 12:51–57. doi:10.1007/s10570-004-0212-1

Bohrn R, Potthast A, Rosenau T, Sixta H, Kosma P (2005) Synthesis and testing of a novel fluorescence label for carboxyls in carbohydrates and cellulosics. Synlett 20:3087–3090. doi:10.1055/s-2005-921923

Bohrn R, Potthast A, Schiehser S, Rosenau T, Sixta H, Kosma P (2006) The FDAM method: determination of carboxyl profiles in cellulosic materials by combining group-selective fluorescence labeling with GPC. Biomacromolecules 7:1743–1750. doi:10.1021/bm060039h

De Feijter JA, Benjamins J, Veer FA (1978) Ellipsometry as a tool to study the adsorption behavior of synthetic and biopolymers at the air–water interface. Biopolymers 17:1758–1772. doi:10.1002/bip.1978.360170711

Delgado ÁV, González-Caballero F, Hunter RJ, Koopal LK, Lyklema J (2007) Measurement and interpretation of electrokinetic phenomena. J Colloid Interface Sci 309:194–224. doi:10.1016/j.jcis.2006.12.075

Dubé M, Deslandes Y, Marchesault RH (1984) Spherulitic precipitation of cellulose from amine-oxide solutions. J Polym Sci Polym Lett E 22:163–171. doi:10.1002/pol.1984.130220307

Fidale LC, Ruiz N, Heinze T, El Seoud OA (2008) Cellulose swelling by aprotic and protic solvents: What are the similarities and differences? Macromol Chem Phys 209:1240–1254. doi:10.1002/macp.200800021

Fink HP, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26:1473–1524. doi:10.1016/S0079-6700(01)00025-9

Freudenberg U, Zschoche S, Simon F, Janke A, Schmidt K, Behrens SH, Auweter H, Werner C (2005) Covalent immobilization of cellulose layers onto maleic anhydride copolymer thin films. Biomacromolecules 6:1628–1634. doi:10.1021/bm0492529

Isogai A, Kato Y (1998) Preparation of polyuronic acid from cellulose by TEMPO-mediated oxidation. Cellulose 5:153–164. doi:10.1023/A:1009208603673

Jie X, Cao Y, Lin B, Yuan Q (2004) Gas permeation performance of cellulose hollow fiber membranes made from the cellulose/N-methylmorpholine-N-oxide/H2O system. J Appl Polym Sci 91:1873–1880. doi:10.1002/app.2385

Kim CW, Kim DS, Kang SY, Marquez M, Joo YL (2006) Structural studies of electrospun cellulose nanofibers. Polymer 47:5097–5107. doi:10.1016/j.polymer.2006.05.033

Klemm D, Philipp B, Heinze T, Wagenknecht W (1998) Comprehensive cellulose chemistry, vol 1: fundamentals and analytical methods. Wiley, Weinheim

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. doi:10.1002/anie.200460587

Kolpak FJ, Blackwell J (1976) Determination of the structure of cellulose II. Macromolecules 9:273–278. doi:10.1021/ma60050a019

Li HJ, Cao YM, Qin JJ, Jie XM, Wang TH, Liu JH, Yuan Q (2006) Development and characterization of anti-fouling cellulose hollow fiber UF membranes for oil–water separation. J Membr Sci 279:328–335. doi:10.1016/j.memsci.2005.12.025

Lide DR, Frederiske HPR (1995) CRC Handbook of chemistry and physics. CRC Press, Boca Raton

Liebner F, Potthast A, Haimer E, Wendland M, Rosenau T (2008) Cellulose aerogels: highly porous, ultra-lightweight materials. Holzforschung 62:129–135. doi:10.1515/HF.2008.051

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. doi:10.1039/C0CS00108B

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082. doi:10.1021/ja0257319

Notley SM, Pettersson B, Wågberg L (2004) Direct measurement of attractive van der Waals’ Forces between regenerated cellulose surfaces in an aqueous environment. J Am Chem Soc 126:13930–13931. doi:10.1021/ja045992d

Ogieglo W, Wormeester H, Eichhorn KJ, Wessling M, Benes NE (2015) In situ ellipsometry studies on swelling of thin polymer films: a review. Prog Polym Sci 42:42–78. doi:10.1016/j.progpolymsci.2014.09.004

Oh SY, Yoo DI, Shin Y, Kim HC, Kim HY, Chung YS, Park WH, Youk JH (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391. doi:10.1016/j.carres.2005.08.007

Potthast A, Röhrling J, Rosenau T, Borgards A, Sixta H, Kosma P (2003) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 3. Monitoring oxidative processes. Biomacromolecules 4:743–749. doi:10.1021/bm025759c

Röhrling J, Potthast A, Rosenau T, Lange T, Ebner G, Sixta H, Kosma P (2002a) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 1. Method development. Biomacromolecules 3:959–968. doi:10.1021/bm020029q

Röhrling J, Potthast A, Rosenau T, Lange T, Borgards A, Sixta H, Kosma P (2002b) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 2. Validation and applications. Biomacromolecules 3:969–975. doi:10.1021/bm020030p

Rosenau T, Potthast A, Sixta H, Kosma P (2001) The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (Lyocell process). Prog Polym Sci 26:1763–1837. doi:10.1016/S0079-6700(01)00023-5

Sahin HT, Arslan MB (2008) A study on physical and chemical properties of cellulose paper immersed in various solvent mixtures. Int J Mol Sci 9:78–88. doi:10.3390/ijms9010078

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. doi:10.1021/bm0703970

Tahiri C, Mignon MR (2000) TEMPO-oxidation of cellulose: synthesis and characterisation of polyglucuronans. Cellulose 7:177–188. doi:10.1023/A:1009276009711

Yokota S, Kitaoka T, Opietnik M, Rosenau T, Wariishi H (2008) Synthesis of gold nanoparticles for in situ conjugation with structural carbohydrates. Angew Chem Int Ed 47:9866–9869. doi:10.1002/anie.200803922

Zimmermann R, Dukhin SS, Werner C, Duval JFL (2013) On the use of electrokinetics for unraveling charging and structure of soft planar polymer films. Curr Opin Colloid Interface Sci 18:83–92. doi:10.1016/j.cocis.2013.02.001

Acknowledgments

The financial support of the Austrian Christian Doppler Research Society (Lab for “Advanced Cellulose Chemistry and Analytics” at BOKU University Vienna) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Ralf Zimmermann and Yvonne Müller have equally contributed to this paper.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zimmermann, R., Müller, Y., Freudenberg, U. et al. Oxidation and structural changes in NMMO-regenerated cellulose films. Cellulose 23, 3535–3541 (2016). https://doi.org/10.1007/s10570-016-1084-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1084-x