Abstract

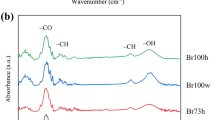

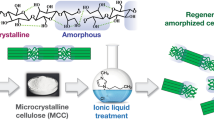

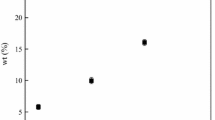

Ionic liquid plasticized cellulose (IPC) materials were prepared with microcrystalline cellulose (MCC) and 25–70 wt% 1-butyl-3-methylimidazolium chloride (BmimCl) by direct thermal processing. Their chemical, morphological and crystalline structures were characterized by Fourier transform infrared spectroscopy, scanning electron microscopy and X-ray diffraction, and their glass transition behaviors and mechanical properties were discussed. The results show there is no chemical reaction between cellulose and the ionic liquid. BmimCl only acts as a plasticizer to improve the thermal processability of MCC, the IPC materials show only one glass transition terrace and can be processed repeatedly. Based on the free volume transition and the percolation of continuous hydrogen bonding networks, the effects of free volume and H-bonding interactions on the glass transition have been differentiated. Furthermore, the phase diagram with four regions has been plotted for IPC materials, which is useful to optimize the thermal processing and modulate the properties of cellulose materials.

Graphical abstract

Similar content being viewed by others

Abbreviations

- MCC:

-

Microcrystalline cellulose

- T g :

-

Glass transition temperature

- IPC:

-

Ionic liquid plasticized cellulose

- FT-IR:

-

Fourier transform infrared spectroscopy

- DSC:

-

Differential scanning calorimetry

- XRD:

-

X-ray diffraction

- SEM:

-

Scanning electron microscopy

- G-T/K-B equation:

-

Gordon-Taylor/Kelley-Bueche equation

References

Bizot H, LeBail P, Leroux B, Davy J, Roger P, Buleon A (1997) Calorimetric evaluation of the glass transition in hydrated, linear and branched polyanhydroglucose compounds. Carbohydr Polym 32:33–50

Brovchenko I, Andrews MN, Oleinikova A (2011) Thermal stability of the hydrogen-bonded water network in the hydration shell of islet amyloid polypeptide. J Phys Condens Matter 23:155105

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548

Calahorra ME, Cortázar M, Eguiazábal JI, Guzmán GM (1989) Thermogravimetric analysis of cellulose: effect of the molecular weight on thermal decomposition. J Appl Polym Sci 37:3305–3314

Chen W, Lickfield GC, Yang CQ (2004) Molecular modeling of cellulose in amorphous state. Part I: model building and plastic deformation study. Polymer 45:1063–1071

Choi SY, Rodriguez H, Mirjafari A, Gilpin DF, McGrath S, Malcolm KR, Tunney MM, Rogers RD, McNally T (2011) Dual functional ionic liquids as plasticisers and antimicrobial agents for medical polymers. Green Chem 13:1527–1535

Choi SY, Rodriguez H, Gunaratne HQN, Puga AV, Gilpin D, McGrath S, Vyle JS, Tunney MM, Rogers RD, McNally T (2014) Dual functional ionic liquids as antimicrobials and plasticisers for medical grade PVCs. RSC Adv 4:8567–8581

Diddens I, Murphy B, Krisch M, Müller M (2008) Anisotropic elastic properties of cellulose measured using inelastic X-ray scattering. Macromolecules 41:9755–9759

Duchemin BJC, Newman RH, Staiger MP (2009) Structure–property relationship of all-cellulose composites. Compos Sci Technol 69:1225–1230

Dupont A-L (2003) Cellulose in lithium chloride/N, N-dimethylacetamide, optimisation of a dissolution method using paper substrates and stability of the solutions. Polymer 44:4117–4126

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Galiński M, Lewandowski A, Stępniak I (2006) Ionic liquids as electrolytes. Electrochim Acta 51:5567–5580

Gericke M, Trygg J, Fardim P (2013) Functional cellulose beads: preparation, characterization, and applications. Chem Rev 113:4812–4836

Gordon M, Taylor JS (1952) Ideal copolymers and the second-order transitions of synthetic rubbers. I. Non-crystalline copolymers. J Appl Chem 2:493–500

Han D, Yan L (2010) Preparation of all-cellulose composite by selective dissolving of cellulose surface in PEG/NaOH aqueous solution. Carbohydr Polym 79:614–619

Hancock B, Zografi G (1994) The relationship between the glass transition temperature and the water content of amorphous pharmaceutical solids. Pharm Res 11:471–477

Huber T, Müssig J, Curnow O, Pang S, Bickerton S, Staiger MP (2011) A critical review of all-cellulose composites. J Mater Sci 47:1171–1186

Jacobsen S, Fritz HG (1999) Plasticizing polylactide—the effect of different plasticizers on the mechanical properties. Polym Eng Sci 39:1303–1310

Johnson DL (1969) Compounds dissolved in cyclic amine oxides. US Patent 3,447,939

Kim J-W, Park S, Harper DP, Rials TG (2013) Structure and thermomechanical properties of stretched cellulose films. J Appl Polym Sci 128:181–187

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Lindman B, Karlström G, Stigsson L (2010) On the mechanism of dissolution of cellulose. J Mol Liq 156:76–81

Mamleev V, Bourbigot S, Yvon J (2007) Kinetic analysis of the thermal decomposition of cellulose: the main step of mass loss. J Anal Appl Pyrolysis 80:151–165

Mateyawa S, Xie DF, Truss RW, Halley PJ, Nicholson TM, Shamshina JL, Rogers RD, Boehm MW, McNally T (2013) Effect of the ionic liquid 1-ethyl-3-methylimidazolium acetate on the phase transition of starch: dissolution or gelatinization? Carbohydr Polym 94:520–530

Mazeau K, Heux L (2003) Molecular dynamics simulations of bulk native crystalline and amorphous structures of cellulose. J Phys Chem B 107:2394–2403

Medronho B, Romano A, Miguel MG, Stigsson L, Lindman B (2012) Rationalizing cellulose (in)solubility: reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 19:581–587

Nishino T, Takano K, Nakamae K (1995) Elastic modulus of the crystalline regions of cellulose polymorphs. J Polym Sci Polym Phys 33:1647–1651

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Ibeta from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082

Paes SS, Sun S, MacNaughtan W, Ibbett R, Ganster J, Foster TJ, Mitchell JR (2010) The glass transition and crystallization of ball milled cellulose. Cellulose 17:693–709

Pinkert A, Marsh KN, Pang SS, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728

Reddy MM, Vivekanandhan S, Misra M, Bhatia SK, Mohanty AK (2013) Biobased plastics and bionanocomposites: current status and future opportunities. Prog Polym Sci 38:1653–1689

Roig F, Dantras E, Dandurand J, Lacabanne C (2011) Influence of hydrogen bonds on glass transition and dielectric relaxations of cellulose. J Phys Appl Phys 44:045403

Samayam IP, Hanson BL, Langan P, Schall CA (2011) Ionic-liquid induced changes in cellulose structure associated with enhanced biomass hydrolysis. Biomacromolecules 12:3091–3098

Sankri A, Arhaliass A, Dez I, Gaumont AC, Grohens Y, Lourdin D, Pillin I, Rolland-Sabaté A, Leroy E (2010) Thermoplastic starch plasticized by an ionic liquid. Carbohydr Polym 82:256–263

Schneider HA (1989) Glass transition behaviour of compatible polymer blends. Polymer 30:771–779

Schroeter J, Felix F (2005) Melting cellulose. Cellulose 12:159–165

Scott MP, Brazel CS, Benton MG, Mays JW, Holbrey JD, Rogers RD (2002) Application of ionic liquids as plasticizers for poly(methyl methacrylate). Chem Commun 1370–1371

Shi X, Zhang L, Cai J, Cheng G, Zhang H, Li J, Wang X (2011) A facile construction of supramolecular complex from polyaniline and cellulose in aqueous system. Macromolecules 44:4565–4568

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124:4974–4975

Szcześniak L, Rachocki A, Tritt-Goc J (2008) Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 15:445–451

Wang H, Gurau G, Rogers RD (2012) Ionic liquid processing of cellulose. Chem Soc Rev 41:1519–1537

Wang QY, Cai J, Zhang LN, Xu M, Cheng H, Han CC, Kuga S, Xiao J, Xiao R (2013) A bioplastic with high strength constructed from a cellulose hydrogel by changing the aggregated structure. J Mater Chem A 1:6678–6686

Yamamuro O, Minamimoto Y, Inamura Y, Hayashi S, Hamaguchi H-O (2006) Heat capacity and glass transition of an ionic liquid 1-butyl-3-methylimidazolium chloride. Chem Phys Lett 423:371–375

Zhang XQ, Wu XL, Gao DC, Xia KN (2012) Bulk cellulose plastic materials from processing cellulose powder using back pressure-equal channel angular pressing. Carbohydr Polym 87:2470–2476

Zografi G, Kontny MJ, Yang AYS, Brenner GS (1984) Surface area and water vapor sorption of macrocrystalline cellulose. Int J Pharm 18:99–116

Acknowledgments

The authors acknowledge the financial support of the National Basic Research Program of China (973 Program, 2012CB025903), the National Natural Science Foundation of China (51210004, 51373060) and the Chinese Ministry of Education (NCET-11-0174). We also thank the Analytical and Testing Center of HUST for SEM and XRD measurements.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, J., Bai, J., Xue, Z. et al. Insight into glass transition of cellulose based on direct thermal processing after plasticization by ionic liquid. Cellulose 22, 89–99 (2015). https://doi.org/10.1007/s10570-014-0502-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0502-1