Abstract

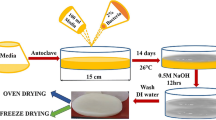

Structural properties of bacterial cellulose (BC) depend on the microstructure of the material, which in turn is influenced by the bacterial strain. This paper reports the production of BC thin films from two bacterial strains, gluconacetobacter xylinus (GX) and gluconacetobacter europaeus (GE), and three methods of drying the films; at room temperature, freeze drying and supercritical drying. The porosity, transparency, water absorption capacity (WAC) and mechanical properties of the obtained films are further investigated. We conclude that materials with different properties can be fabricated by selecting the bacterial strain or the drying method. Supercritical drying of films of GE achieved mechanically robust and extremely light films, 0.05 g/mL, with up to 96 % of porosity, and with a WAC up 110 times their dried weight. We determined that materials resulting from GE strain are not much affected by the drying method. On the other hand, GX produced BC films more sensitive to the drying method used. Films are denser, 0.6–0.2 g/mL, with tunable porosity from 60 to 90 % and their maximum WAC is 66 times their dried weight.

Similar content being viewed by others

References

Andrade F, Alexandre N, Amorim I, Gartner F, Mauricio A, Luis AL, Gama M (2013) Studies on the biocompatibility of bacterial cellulose. J Bioact Compat Polym 28(1):97–112

Andrés Barrao C, Falquet L, Calderon Copete S, Descombes P, Perez R, Ortega Pérez R, Barja F (2011) Genome sequences of the high-acetic acid-resistant bacteria Gluconacetobacter europaeus LMG 18890T and G. europaeus LMG 18494 (reference strains), G. europaeus 5P3, and Gluconacetobacter oboediens 174Bp2 (isolated from vinegar). J Bacteriol 193(10):2670–2671

Cameron AR, Frith JE, Cooper-White JJ (2011) The influence of substrate creep on mesenchymal stem cell behaviour and phenotype. Biomaterials 32(26):5979–5993. doi:10.1016/j.biomaterials.2011.04.003

Chin SF, Romainor ANB, Pang SC (2014) Fabrication of hydrophobic and magnetic cellulose aerogel with high oil absorption capacity. Mater Lett 115:241–243. doi:10.1016/j.matlet.2013.10.061

Czaja WK, Young DJ, Kawecki M, Brown RM (2007) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8(1):1–12. doi:10.1021/bm060620d

Das K, Ray D, Bandyopadhyay NR, Sengupta S (2010) Study of the properties of microcrystalline cellulose particles from different renewable resources by XRD, FTIR, Nanoindentation, TGA and SEM. J Polym Environ 18(3):355–363

Dietrich A, Goring DAI, Revol JF (1987) Effect of mercerization on the crystallite size and crystallinity index in cellulose from different sources. Can J Chem 65(8):1724–1725

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I→ cellulose II. Cellulose 9(1):7–18. doi:10.1023/a:1015877021688

Engler A, Bacakova L, Newman C, Hategan A, Griffin M, Discher D (2004) Substrate compliance versus ligand density in cell on gel responses. Biophys J 86(1):617–628. doi:10.1016/S0006-3495(04)74140-5

French A (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896. doi:10.1007/s10570-013-0030-4

Fu L, Zhang J, Yang G (2013) Present status and applications of bacterial cellulose-based materials for skin tissue repair. Carbohydr Polym 92(2):1432–1442. doi:10.1016/j.carbpol.2012.10.071

Gatenholm P, Klemm D (2010) Bacterial nanocellulose as a renewable material for biomedical applications. MRS Bull 35(03):208–213. doi:10.1557/mrs2010.653

Gavillon R, Budtova T (2008) Aerocellulose: new highly porous cellulose prepared from cellulose–NaOH aqueous solutions. Biomacromolecules 9(1):269–277. doi:10.1021/bm700972k

George J, Ramana KV, Sabapathy SN, Jagannath JH, Bawa AS (2005) Characterization of chemically treated bacterial (Acetobacter xylinum) biopolymer: some thermo-mechanical properties. Int J Biol Macromol 37(4):189–194. doi:10.1016/j.ijbiomac.2005.10.007

George J, Sajeevkumar VA, Kumar R, Ramana KV, Sabapathy SN, Bawa AS (2008) Enhancement of thermal stability associated with the chemical treatment of bacterial (Gluconacetobacter xylinus) cellulose. J Appl Polym Sci 108(3):1845–1851. doi:10.1002/app.27802

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. II. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345–352

Hoepfner S, Ratke L, Milow B (2008) Synthesis and characterisation of nanofibrillar cellulose aerogels. Cellulose 15(1):121–129. doi:10.1007/s10570-007-9146-8

Hu W, Chen S, Yang J, Li Z, Wang H (2014a) Functionalized bacterial cellulose derivatives and nanocomposites. Carbohydr Polym 101:1043–1060. doi:10.1016/j.carbpol.2013.09.102

Hu W, Chen S, Yang J, Li Z, Wang H (2014b) Functionalized bacterial cellulose derivatives and nanocomposites. Carbohydr Polym 101:1043–1060. doi:10.1016/j.carbpol.2013.09.102

Innerlohinger J, Weber HK, Kraft G (2006) Aerocellulose: aerogels and aerogel-like materials made from cellulose. Macromol Symp 244(1):126–135. doi:10.1002/masy.200651212

Jin H, Kettunen M, Laiho A, Pynnonen H, Paltakari J, Marmur A, Ikkala O, Ras RHA (2011) Superhydrophobic and superoleophobic nanocellulose aerogel membranes as bioinspired cargo carriers on water and oil. Langmuir 27(5):1930–1934. doi:10.1021/la103877r

Kalia S, Kaith BS, Kaur I (2011) Cellulose fibers: bio- and nano-polymer composites. Green chemistry and technology. Springer, Berlin. doi:10.1007/978-3-642-17370-7

Kim D-Y, Nishiyama Y, Kuga S (2002) Surface acetylation of bacterial cellulose. Cellulose 9(3–4):361–367. doi:10.1023/a:1021140726936

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog Polym Sci 26:1561–1603

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed Engl 44(22):3358–3393. doi:10.1002/anie.200460587

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466. doi:10.1002/anie.201001273

Liebner F, Haimer E, Wendland M, Neouze MA, Schlufter K, Miethe P, Heinze T, Potthast A, Rosenau T (2010) Aerogels from unaltered bacterial cellulose: application of scCO(2) drying for the preparation of shaped, ultra-lightweight cellulosic aerogels. Macromol Biosci 10(4):349–352. doi:10.1002/mabi.200900371

Ma S, Mi Q, Yu J, He J, Zhang J (2014) Aerogel materials based on cellulose. Prog Chem 26(5):796–809. doi:10.7536/pc131032

Mansikkamaki P, Lahtinen M, Rissanen K (2007) The conversion from cellulose I to cellulose II in NaOH mercerization performed in alcohol–water systems: an X-ray powder diffraction study. Carbohydr Polym 68(1):35–43. doi:10.1016/j.carbpol.2006.07.010

Moner-Girona M, Roig A, Molins E, Martinez E, Esteve J (1999) Micromechanical properties of silica aerogels. Appl Phys Lett 75(5):653–655. doi:10.1063/1.124471

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994. doi:10.1039/c0cs00108b

Moore SW, Roca-Cusachs P, Sheetz MP (2010) Stretchy proteins on stretchy substrates: the important elements of integrin-mediated rigidity sensing. Dev Cell 19(2):194–206. doi:10.1016/j.devcel.2010.07.018

Mwaikambo LY, Ansell MP (2001) The determination of porosity and cellulose content of plant fibers by density methods. J Mater Sci Lett 20(23):2095–2096. doi:10.1023/a:1013703809964

Nata IF, Sureshkumar M, Lee C-K (2011) One-pot preparation of amine-rich magnetite/bacterial cellulose nanocomposite and its application for arsenate removal. RSC Adv 1(4):625–631. doi:10.1039/c1ra00153a

Nimeskern L, Martínez Ávila H, Sundberg J, Gatenholm P, Müller R, Stok KS (2013) Mechanical evaluation of bacterial nanocellulose as an implant material for ear cartilage replacement. J Mech Behav Biomed Mater 22:12–21. doi:10.1016/j.jmbbm.2013.03.005

Pelham RJ, Y-l Wang (1997) Cell locomotion and focal adhesions are regulated by substrate flexibility. Proc Natl Acad Sci 94(25):13661–13665

Pinto RJB, Neves MC, Neto CP, Trindade T (2012) Composites of cellulose and metal nanoparticles. In: Ebrahimi F (ed) Nanotechnology and nanomaterials, Nanocomposites - new trends and developments, InTech, September 27, 2012 under CC BY 3.0 license. doi:10.5772/50553

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in bacteria. Microbiol Rev 55(1):35–58

Rowlands AS, George PA, Cooper-White JJ (2008) Directing osteogenic and myogenic differentiation of MSCs: interplay of stiffness and adhesive ligand presentation. Am J Physiol Cell Physiol 295(4):C1037–C1044. doi:10.1152/ajpcell.67.2008

Sai H, Xing L, Xiang J, Cui L, Jiao J, Zhao C, Li Z, Li F (2013) Flexible aerogels based on an interpenetrating network of bacterial cellulose and silica by a non-supercritical drying process. J Mater Chem A 1(27):7963–7970. doi:10.1039/c3ta11198a

Saska S, Teixeira LN, de Oliveira PT, Gaspar AMM, Ribeiro SJL, Messaddeq Y, Marchetto R (2012) Bacterial cellulose–collagen nanocomposite for bone tissue engineering. J Mater Chem 22(41):22102–22112. doi:10.1039/c2jm33762b

Schutz C, Sort J, Bacsik Z, Oliynyk V, Pellicer E, Fall A, Wagberg L, Berglund L, Bergstrom L, Salazar-Alvarez G (2012) Hard and transparent films formed by nanocellulose-TiO2 nanoparticle hybrids. PLoS One 7(10). doi:10.1371/journal.pone.0045828

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794. doi:10.1177/004051755902901003

Sehaqui H, Zhou Q, Berglund LA (2011a) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71(13):1593–1599. doi:10.1016/j.compscitech.2011.07.003

Sehaqui H, Zhou Q, Ikkala O, Berglund LA (2011b) Strong and tough cellulose nanopaper with high specific surface area and porosity. Biomacromolecules 12(10):3638–3644. doi:10.1021/bm2008907

Shezad O, Khan S, Khan T, Park JK (2010) Physicochemical and mechanical characterization of bacterial cellulose produced with an excellent productivity in static conditions using a simple fed-batch cultivation strategy. Carbohydr Polym 82(1):173–180. doi:10.1016/j.carbpol.2010.04.052

Shi ZJ, Zhang Y, Phillips GO, Yang G (2014) Utilization of bacterial cellulose in food. Food Hydrocoll 35:539–545. doi:10.1016/j.foodhyd.2013.07.012

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2(4):728–765. doi:10.3390/polym2040728

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. doi:10.1007/s10570-010-9405-y

Sun CQ (2005) True density of microcrystal line cellulose. J Pharm Sci 94(10):2132–2134. doi:10.1002/jps.20459

Svensson A, Nicklasson E, Harrah T, Panilaitis B, Kaplan DL, Brittberg M, Gatenholm P (2005) Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 26(4):419–431. doi:10.1016/j.biomaterials.2004.02.049

Ul-Islam M, Shah N, Ha JH, Park JK (2011) Effect of chitosan penetration on physico-chemical and mechanical properties of bacterial cellulose. Korean J Chem Eng 28(8):1736–1743. doi:10.1007/s11814-011-0042-4

Ul-Islam M, Khan T, Park JK (2012a) Nanoreinforced bacterial cellulose–montmorillonite composites for biomedical applications. Carbohydr Polym 89(4):1189–1197. doi:10.1016/j.carbpol.2012.03.093

Ul-Islam M, Khan T, Park JK (2012b) Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohydr Polym 88(2):596–603. doi:10.1016/j.carbpol.2012.01.006

Ummartyotin S, Juntaro J, Sain M, Manuspiya H (2012) Development of transparent bacterial cellulose nanocomposite film as substrate for flexible organic light emitting diode (OLED) display. Ind Crop Prod 35(1):92–97. doi:10.1016/j.indcrop.2011.06.025

Steinbüchel A, Vandamme EJ, De Baets S, Steinbüchel A, Vandamme EJ, Hofrichter M, De Baets S (eds) (2002) Polysaccharides I: polysaccharides from prokaryotes, vol 5. Biopolymers. Wiley, University of California

Wada M, Sugiyama J, Okano T (1993) Native celluloses on the basis of two crystalline phase (Iα/Iβ) system. J Appl Polym Sci 49(8):1491–1496. doi:10.1002/app.1993.070490817

Wada M, Okano T, Sugiyama J (1997) Synchrotron-radiated X-ray and neutron diffraction study of native cellulose. Cellulose 4(3):221–232. doi:10.1023/a:1018435806488

Wang Y, Zhao Y, Deng Y (2008) Effect of enzymatic treatment on cotton fiber dissolution in NaOH/urea solution at cold temperature. Carbohydr Polym 72(1):178–184

W-h Guo, Frey MT, Burnham NA, Wang Y-l (2006) Substrate rigidity regulates the formation and maintenance of tissues. Biophys J 90(6):2213–2220

Wicklein B, Salazar-Alvarez G (2013) Functional hybrids based on biogenic nanofibrils and inorganic nanomaterials. J Mater Chem A 1(18):5469–5478. doi:10.1039/c3ta01690k

Wu Z-Y, Li C, Liang H-W, Chen J-F, Yu S-H (2013a) Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angew Chem Int Ed 52(10):2925–2929. doi:10.1002/anie.201209676

Wu ZY, Li C, Liang HW, Chen JF, Yu SH (2013b) Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angew Chem Int Ed Engl 52(10):2925–2929. doi:10.1002/anie.201209676

Yamada Y, Hoshino K, Ishikawa T (1997) The phylogeny of acetic acid bacteria based on the partial sequences of 16S ribosomal RNA: the elevation of the subgenus Gluconoacetobacter to the generic level. Biosci Biotechnol Biochem 61(8):1244–1251

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, Handa K (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17(2):153. doi:10.1002/adma.200400597

Zeng M, Laromaine A, Feng W, Levkin PA, Roig A (2014) Origami magnetic cellulose: controlled magnetic fraction and patterning of flexible bacterial cellulose. J Mater Chem C. doi:10.1039/c4tc00787e

Zhang L, Ruan D, Zhou J (2001) Structure and properties of regenerated cellulose films prepared from cotton linters in NaOH/urea aqueous solution. Ind Eng Chem Res 40(25):5923–5928

Acknowledgments

The research leading to these results has received funding from the People Program (Marie Curie Actions) of the European Union’s Seventh Framework Program (FP7/2007-2013) under REA grant agreement no 303630 and cofounded by the European Social Fund. Authors acknowledge the funding from Spanish Ministry of Economy MAT 2012-35324, from the Generalitat de Catalunya 2014SGR213, COST Action MP1202, Ramon y Cajal grant RYC-2010-06082 (AL), and Chinese Scholarship Council fellowship (MZ). The group of Dr. Alex Peralvarez for their help in the bacterial culture, Dr. Josep PuigMartí and the group of Prof. David Amabilino for the use of the optical microscope, Prof. Elies Molins and Toni Pons for the use and training in the use of the freeze drier and Dr. Roberto L. Guzman de Villoria for his advices in the mechanical measurements.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zeng, M., Laromaine, A. & Roig, A. Bacterial cellulose films: influence of bacterial strain and drying route on film properties. Cellulose 21, 4455–4469 (2014). https://doi.org/10.1007/s10570-014-0408-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0408-y