Abstract

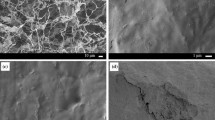

Freeze-dried nanofibrillated cellulose based-aerogels were produced from cellulosic pulps extracted from Eucalyptus urograndis. Nanofibers were isolated under high pressure and modified with TEMPO-mediated oxidation and/or hydroxyapatite (HAp) to observe potential changes in mechanical properties. Two degrees of oxidation (DO), 0.1 and 0.2, were achieved as measured by conductimetric titration. Oxidized and non-oxidized samples were modified with HAp at a ratio of HAp:cellulose of 0.2:1. Morphology (FE-SEM), pore size, surface area, and mechanical properties were obtained to characterize the produced aerogels. The results clearly demonstrate a homogeneous morphology for aerogels fabricated with oxidized cellulose nanofibers. The nature of water present in the material was measured using time domain-nuclear magnetic resonance spectroscopy (TD-NMR) and demonstrated that it played a key role in the development of the porous and uniform micro-architecture. TEMPO-mediated oxidation and the addition of HAp resulted in aerogels with high mechanical strength as demonstrated from an increase from approximately 75–200 kPa in compressive strength when reduced to 50 % of their original height. However, the contribution of oxidation to the mechanical properties was more pronounced than the addition of HAp. In general, the density of the aerogels varied from 0.008 to 0.011 g/cm3 in which slightly lightweight aerogels were produced by increasing the degree of oxidation, whereas the incorporation of HAp as a modifying agent for potential bio-based tissue scaffolding matrices did not significantly contribute to higher densities.

Similar content being viewed by others

References

Archer EA, Gong H, Krische MJ (2001) Hydrogen bonding in noncovalent synthesis: selectivity and the directed organization of molecular strands. Tetrahedron 57:1139–1159

Aulin C, Netrval J, Wagberg L, Lindstrom T (2010) Aerogels from nanofibrillated cellulose with tunable oleophobicity. Soft Matter 6(14):3298–3305

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84(3):975–983

Bragd PL, van Bekkum H, Besemer AC (2004) TEMPO-Mediated oxidation of polysaccharides: survey of methods and applications. Top Catal 27:49–66

Burchell MJ, Creighton JA, Cole MJ, Mann J, Kearsley AT (2001) Capture of particles in hypervelocity impacts in aerogel. Meteorit Planet Sci 36(2):209–221

da Silva Perez D, Montanari S, Vignon MR (2003) TEMPO-Mediated oxidation of cellulose III. Biomacromolecules 4(5):1417–1425

de Nooy AEJ, Besemer AC, van Bekkum H (1995) Highly selective nitroxyl radical-mediated oxidation of primary alcohol groups in water-soluble glucans. Carbohydr Res 269(1):89–98

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch–cellulose microfibril composites. J Appl Polym Sci 76(14):2080–2092

Elder T, Labbé N, Harper D, Rials T (2006) Time domain-nuclear magnetic resonance study of chars from southern hardwoods. Biomass Bioenergy 30(10):855–862

Felby C, Thygesen L, Kristensen J, Jørgensen H, Elder T (2008) Cellulose–water interactions during enzymatic hydrolysis as studied by time domain NMR. Cellulose 15(5):703–710

Gavillon R, Budtova T (2007) Aerocellulose: new highly porous cellulose prepared from cellulose−naoh aqueous solutions. Biomacromolecules 9(1):269–277

Gawryla MD, van den Berg O, Weder C, Schiraldi DA (2009) Clay aerogel/cellulose whisker nanocomposites: a nanoscale wattle and daub. J Mater Chem 19(15):2118–2124

Habibi Y, Chanzy H, Vignon M (2006) TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 13(6):679–687

Heath L, Thielemans W (2010) Cellulose nanowhisker aerogels. Green Chem 12(8):1448–1453

Hoepfner S, Ratke L, Milow B (2008) Synthesis and characterisation of nanofibrillar cellulose aerogels. Cellulose 15(1):121–129

Hong L, Wang YL, Jia SR, Huang Y, Gao C, Wan YZ (2006) Hydroxyapatite/bacterial cellulose composites synthesized via a biomimetic route. Mater Lett 60(13–14):1710–1713

Innerlohinger J, Weber HK, Kraft G (2006) Aerocellulose: aerogels and aerogel-like materials made from cellulose. Macromol Symp 244(1):126–135

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85

Kwak DH, Hong SJ, Kim DJ, Greil P (2010) The formation of hydroxyapatite on chemically-modified cellulose fibers. J Ceram Process Res 11(2):170–172

Liebner F, Potthast A, Rosenau T, Haimer E, Wendland M (2008) Cellulose aerogels: highly porous, ultra-lightweight materials. Holzforschung 62(2):129–135

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11(6):1696–1700

Paakko M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindstrom T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4(12):2492–2499

Park S, Venditti RA, Jameel H, Pawlak JJ (2006) Changes in pore size distribution during the drying of cellulose fibers as measured by differential scanning calorimetry. Carbohydr Polym 66(1):97–103

Saito T, Isogai A (2006) Wet strength improvement of TEMPO-oxidized cellulose sheets prepared with cationic polymers. Ind Eng Chem Res 46(3):773–780

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from tempo-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by tempo-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491

Sehaqui H, Allais M, Zhou Q, Berglund LA (2011a) Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Comp Sci Technol 71(3):382–387

Sehaqui H, Zhou Q, Berglund LA (2011b) Nanostructured biocomposites of high toughness – a wood cellulose nanofiber network in ductile hydroxyethylcellulose matrix. Soft Matter 7(16):7342–7350

Suh DJ, Park T-J (1996) Sol−Gel strategies for pore size control of high-surface-area transition-metal oxide aerogels. Chem Mater 8(2):509–513

Wan YZ, Hong L, Jia SR, Huang Y, Zhu Y, Wang YL, Jiang HJ (2006) Synthesis and characterization of hydroxyapatite-bacterial cellulose nanocomposites. Compos Sci Technol 66(11–12):1825–1832

Wan YZ, Gao C, Luo HL, He F, Liang H, Li XL, Wang YL (2009) Early growth of nano-sized calcium phosphate on phosphorylated bacterial cellulose nanofibers. J Nanosci Nanotechnol 9(11):6494–6500

Zimmermann KA, LeBlanc JM, Sheets KT, Fox RW, Gatenholm P (2011) Biomimetic design of a bacterial cellulose/hydroxyapatite nanocomposite for bone healing applications. Mater Sci Eng C 31(1):43–49

Acknowledgments

We would like to gratefully acknowledge the CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) for the generous provision of a research fellowship to TCFS that allowed parts of this work to be realized. The Authors would also like to thank Professor Robert C. Borden from the Department of Civil, Construction and Environmental Engineering for the generous use of the homogenizer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, T.C.F., Habibi, Y., Colodette, J.L. et al. A fundamental investigation of the microarchitecture and mechanical properties of tempo-oxidized nanofibrillated cellulose (NFC)-based aerogels. Cellulose 19, 1945–1956 (2012). https://doi.org/10.1007/s10570-012-9761-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9761-x