Abstract

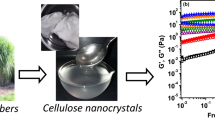

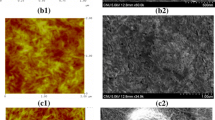

Stable aqueous suspensions of cellulose nano-crystals (CNCs) were fabricated from both native and mercerized cotton fibers by sulfuric acid hydrolysis, followed by high-pressure homogenization. Fourier transform infrared spectrometry and wide-angle X-ray diffraction data showed that the fibers had been transformed from cellulose I (native) to cellulose II (mercerized) crystal structure, and these polymorphs were retained in the nanocrystals, giving CNC-I and CNC-II. Transmission electron microscopy showed rod-like crystal morphology for both types of crystals under the given processing conditions with CNC-II having similar width but reduced length. Freeze-dried agglomerates of CNC-II had a much higher bulk density than that of CNC-I. Thermo-gravimetric analysis showed that CNC-II had better thermal stability. The storage moduli of CNC-II suspensions at all temperatures were substantially larger than those of CNC-I suspensions at the same concentration level. CNC-II suspensions and gels were more stable in response to temperature increases. Films of CNC and Poly(ethylene oxide) were tested. Both CNC-I/PEO and CNC-II/PEO composites showed increased tensile strength and elongation at break compared to pure PEO. However, composites with CNC-II had higher strength and elongation than composites with CNC-I.

Similar content being viewed by others

References

Abidi N, Hequet E, Cabrales L (2010) Changes in sugar composition and cellulose content during the secondary cell wall biogenesis in cotton fibers. Cellulose 17(1):153–160. doi:10.1007/s10570-009-9364-3

Ahn KH, Osaki K (1994) A network model for predicting the shear thickening behavior of a Poly(Vinyl Alcohol) sodium-borate aqueous-solution. J Non-Newton Fluid 55(3):215–227

Atalla RH, VanderHart DL (1984) Native cellulose: a composite of two distinct crystalline forms. Science 223:283–285

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286(10):1173–1180. doi:10.1007/s00396-008-1882-2

Brownsey GJ, Ridout MJ (1985) Rheological characterization of microcrystalline cellulose dispersions: Avicel Rc 591. J Food Technol 20(2):237–243

Chang PR, Ai FJ, Chen Y, Dufresne A, Huang J (2009) Effects of starch nanocrystal-graft-polycaprolactone on mechanical properties of waterborne polyurethane-based nanocomposites. J Appl Polym Sci 111(2):619–627. doi:10.1002/App.29060

Chen X, Zhang YM, Cheng LY, Wang HP (2009) Rheology of concentrated cellulose solutions in 1-butyl-3-methylimidazolium chloride. J Polym Environ 17(4):273–279. doi:10.1007/s10924-009-0149-4

Ciacco GT, Morgado DL, Frollini E, Possidonio S, El Seoud OA (2010) Some aspects of acetylation of untreated and mercerized sisal cellulose. J Braz Chem Soc 21(1):71–77

Das M, Chakraborty D (2006) Influence of alkali treatment on the fine structure and morphology of bamboo fibers. J Appl Polym Sci 102(5):5050–5056. doi:10.1002/App.25105

Deguchi S, Kuroda K, Akiyoshi K, Lindman B, Sunamoto J (1999) Gelation of cholesterol-bearing pullulan by surfactant and its rheology. Colloid Surface A 147(1–2):203–211

Dinand E, Chanzy H, Vignon MR (1996) Parenchymal cell cellulose from sugar beet pulp: preparation and properties. Cellulose 3(3):183–188

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I -> cellulose II. Cellulose 9(1):7–18

Dong XM, Kimura T, Revol JF, Gray DG (1996) Effects of ionic strength on the isotropic-chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir 12(8):2076–2082

El-Wakil NA, Hassan ML (2008) Structural changes of regenerated cellulose dissolved in FeTNa, NaOH/thiourea, and NMMO systems. J Appl Polym Sci 109(5):2862–2871. doi:10.1002/App.28351

Gatenholm P, Klemm D (2010) Bacterial nanocellulose as a renewable material for biomedical applications. MRS Bull 35(3):208–213

George J, Ramana KV, Sabapathy SN, Jagannath JH, Bawa AS (2005) Characterization of chemically treated bacterial (Acetobacter xylinum) biopolymer: some thermo-mechanical properties. Int J Biol Macromol 37(4):189–194. doi:10.1016/j.ijbiomac.2005.10.007

Gwon JG, Lee SY, Doh GH, Kim JH (2010) Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. J Appl Polym Sci 116(6):3212–3219. doi:10.1002/App.31746

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110(6):3479–3500. doi:10.1021/cr900339w

Hirota M, Tamura N, Saito T, Isogai A (2010) Water dispersion of cellulose II nanocrystals prepared by TEMPO-mediated oxidation of mercerized cellulose at pH 4.8. Cellulose 17(2):279–288. doi:10.1007/s10570-009-9381-2

Krebs FC (2008) Degradation and stability of polymer and organic solar cells. Sol Energy Mater Sol Cells 92(7):685. doi:10.1016/j.solmat.2008.01.016

KroonBatenburg LMJ, Kroon J (1997) The crystal and molecular structures of cellulose I and II. Glycoconjugate J 14(5):677–690

Kundu PP, Singh RP (2008) Effect of addition of surfactants on the rheology of gels from methylcellulose in N,N-dimethylformamide. J Appl Polym Sci 108(3):1871–1879. doi:10.1002/App.27839

Langan P, Nishiyama Y, Chanzy H (1999) A revised structure and hydrogen-bonding system in cellulose II from a neutron fiber diffraction analysis. J Am Chem Soc 121(43):9940–9946

Langan P, Nishiyama Y, Chanzy H (2001) X-ray structure of mercerized cellulose II at 1 angstrom resolution. Biomacromolecules 2(2):410–416. doi:10.1021/mb005612q

Liu YP, Hu H (2008) X-ray diffraction study of bamboo fibers treated with NaOH. Fiber Polym 9(6):735–739. doi:10.1007/s12221-008-0115-0

Liu XX, Khor S, Petinakis E, Yu L, Simon G, Dean K, Bateman S (2010) Effects of hydrophilic fillers on the thermal degradation of poly(lactic acid). Thermochim Acta 509(1–2):147–151. doi:10.1016/j.tca.2010.06.015

Lu P, Hsieh YL (2010) Preparation and properties of cellulose nanocrystals: rods, spheres, and network. Carbohyd Polym 82(2):329–336. doi:10.1016/j.carbpol.2010.04.073

Mansikkamaki P, Lahtinen M, Rissanen K (2005) Structural changes of cellulose crystallites induced by mercerisation in different solvent systems; determined by powder X-ray diffraction method. Cellulose 12(3):233–242. doi:10.1007/s10570-004-3132-1

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen bonding system in cellulose 1(alpha), from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125(47):14300–14306. doi:10.1021/Ja037055w

Nishiyama Y, Johnson GP, French AD, Forsyth VT, Langan P (2008) Neutron crystallography, molecular dynamics, and quantum mechanics studies of the nature of hydrogen bonding in cellulose I-beta. Biomacromolecules 9(11):3133–3140. doi:10.1021/Bm800726v

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohyd Res 340(3):417–428. doi:10.1016/j.carres.2004.11.027

Park JM, Kim SJ, Jang JH, Wang ZJ, Kim PG, Yoon DJ, Kim J, Hansen G, DeVries KL (2008) Actuation of electrochemical, electro-magnetic, and electro-active actuators for carbon nanofiber and Ni nanowire reinforced polymer composites. Compos Part B-Eng 39(7–8):1161–1169. doi:10.1016/j.compositesb.2008.03.009

Paszner L (1968) Effect of inter- and intra-crystalline swelling on cellulose degradation by gamma-rays. Svensk Papperstidning-Nordisk Cellulosa 71(22):822

Ray D, Sarkar BK (2001) Characterization of alkali-treated jute fibers for physical and mechanical properties. J Appl Polym Sci 80(7):1013–1020

Revol JF, Goring DAI (1981) On the mechanism of the mercerization of cellulose in wood. J Appl Polym Sci 26(4):1275–1282

Sauperl O, Stana-Kleinschek K, Ribitsch V (2009) Cotton cellulose 1, 2, 3, 4 buthanetetracarboxylic acid (BTCA) crosslinking monitored by some physical-chemical methods. Text Res J 79(9):780–791. doi:10.1177/0040517508096222

Schwanninger M, Rodrigues JC, Pereira H, Hinterstoisser B (2004) Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36(1):23–40. doi:10.1016/j.vibspec.2004.02.003

Shibazaki H, Kuga S, Okano T (1997) Mercerization and acid hydrolysis of bacterial cellulose. Cellulose 4(2):75–87

Uskokovic V (2008) Composites comprising cholesterol and carboxymethyl cellulose. Colloids Surf B 61(2):250–261. doi:10.1016/j.colsurfb.2007.08.014

Wang N, Ding EY, Cheng RS (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48(12):3486–3493. doi:10.1016/j.polymer.2007.03.062

Wu JJ, Liang SM, Dai HJ, Zhang XY, Yu XL, Cai YL, Zheng LN, Wen N, Jiang B, Xu J (2010) Structure and properties of cellulose/chitin blended hydrogel membranes fabricated via a solution pre-gelation technique. Carbohyd Polym 79(3):677–684. doi:10.1016/j.carbpol.2009.09.022

Yasuda K, Saito M, Kamide K (1993) Flow birefringence and viscosity of cellulose solutions in semidilute regime. Polym Int 30(3):393–400

Zhang JG, Elder TJ, Pu YQ, Ragauskas AJ (2007) Facile synthesis of spherical cellulose nanoparticles. Carbohyd Polym 69(3):607–611. doi:10.1016/j.carbpol.2007.01.019

Zhou CJ, Chu R, Wu R, Wu QL (2011a) Electrospun polyethylene oxide/cellulose nanocrystal composite nanofibrous mats with homogeneous and heterogeneous microstructures. Biomacromolecules 12(7):2617–2625. doi:10.1021/Bm200401p

Zhou CJ, Wu QL, Yue YY, Zhang QG (2011b) Application of rod-shaped cellulose nanocrystals in polyacrylamide hydrogels. J Colloid Interf Sci 353(1):116–123. doi:10.1016/j.jcis.2010.09.035

Zhou CJ, Wu QL, Zhang QG (2011c) Dynamic rheology studies of in situ polymerization process of polyacrylamide-cellulose nanocrystal composite hydrogels. Colloid Polym Sci 289(3):247–255. doi:10.1007/s00396-010-2342-3

Zivanovic S, Li JJ, Davidson PM, Kit K (2007) Physical, mechanical, and antibacterial properties of chitosan/PEO blend films. Biomacromolecules 8(5):1505–1510. doi:10.1021/Bm061140p

Acknowledgments

We are thankful for the financial support from the USDA CSREES (Award No: 2008-38814-04771) and from the National Natural Science Foundation of China (Award No: 31070505 and 31010103905). We also thank Dr. Vince Edwards of the USDA ARS Southern Regional Research Center in New Orleans, LA for providing the fabric material.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yue, Y., Zhou, C., French, A.D. et al. Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19, 1173–1187 (2012). https://doi.org/10.1007/s10570-012-9714-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9714-4