Abstract

Precious metal-titania materials make good catalysts for hydrogen production from a variety of organic substrates using sunlight. These substrates essentially act as reductants for water, by intercepting electrophilic oxygen species generated by electron–hole excitation resulting from photon absorption in the titania support. As a result, the hydrogen produced comes partly from water splitting and partly from dehydrogenation of the organic substrate. Why only precious metals work for the reaction is discussed, together with the mechanism of these reactions. The oxygenate substrates are decarbonylated to produce adsorbed CO, which is removed in the presence of light by the electrophilic oxygen as CO2, but the level of CO2 detected is strongly affected by the amount of liquid water present, due to absorption and reaction to form carbonic acid. The possibilities for application of this technology in the domestic environment, the ‘Photocatalytic Window’ is considered.

Graphical Abstract

Similar content being viewed by others

1 Setting the Scene

The human race is in a period of fast transition in all sorts of aspects of life. Perhaps the most important of these is the changing energy scene. Because of the increase in population and increased industrialisation the most convenient forms of useable energy that are available in large quantity, fossil fuels, have been utilized for energy supply. These are firstly coal, used originally for driving steam generation for the new steam engines invented and widely introduced for manufacturing and transport in England from the late 18th century. Following from this came the widespread use of crude oil for transport, in the form of refined petroleum spirit, and in more recent times increasing use of gas powered electrical power generation and domestic combustion. As a result there has been an increase of CO2 in the atmosphere—increasing from the geologically steady value of about 280 ppm, now just breaking the 400 ppm level, a 42 % increase. The source of these increases can be traced back to the original industrialisation of the early-mid 18th century. Figure 1 illustrates this in terms of the CO2 level in the atmosphere, combined with a derivative which traces the start of this increase to the period just after the development of more efficient forms of steam engines for mechanical power generation see Ref. [1].

A graph showing the increase in CO2 levels, the time derivative of this, and the rise of coal production in the period of industrialization of the UK. The baseline for the latter has been vertically shifted to align it with the pre-industrial CO2 level; there was very little coal production before 1750. All trace the beginnings of the CO2 level increase to the late 18th century. For more discussion of these origins of the CO2 increase see Ref. [1]

The consequences of this geologically fast increase in CO2 levels can be debated, but what is absolutely certain is that, as sentient beings, humans should not be playing with dice by abnormal perturbance of natural equilibrium, over a geologically fast timescale. The results are not likely to be positive for the planet, except in the sense that it might help reduce the human population.

Thus there is an urgent need to stop the CO2 increase and to find new sustainable ways of fuelling our future. Of course we have a number of successful technologies in place which are being applied and made ever more efficient technologically and economically. Wind power and solar power are mainstays of sustainable energy production, but are geographically very variable in efficiency and are often in very variable time-dependence of production, due to often chaotic weather patterns. For that reason storage of such power production in peak times, for use in slack times, is essential. It is recently being appreciated that perhaps the only efficient way of doing this is to store such energy in the form of chemical energy. The way at present being considered is hydrogen production by electrolysis, followed by conversion into a transportable form such as methanol or ammonia [2].

The point of this article is to describe current research in our group and others concerning an alternative way of producing hydrogen that is also direct, namely photocatalytic hydrogen production using sunlight energy and to consider the possibility of utilising such energy in the domestic environment.

2 Basics: Kinetics and Thermodynamics

As always should be the case for determining the feasibility of catalytic reactions we must consider the thermodynamics, which are particularly simple for water splitting: the conclusion from this is that it is an extremely difficult reaction since it is endergonic by ~240 kJ mol−1, as discussed in an earlier review in this journal [3] and elsewhere [4] in more detail.

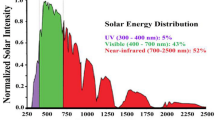

Thus dissociation can be obtained with reasonable equilibrium yields but with very high thermal input at high temperature. The alternative is to provide the thermodynamic energy with light, in which case we need light of ~500 nm wavelength. Such light is abundant on earth, but fortunately for the biota, water is stable because the kinetic barrier to split off the first hydrogen atom from water is much more energy demanding, needing ~500 kJ mol−1, or light of at maximum wavelength 250 nm. Hence water is stable at the earth’s surface—such wavelengths are cut out in the stratosphere before reaching ground level.

Hence we need strategies to get round the kinetic problem and this involves the use of catalysis to lower that barrier. However, as shown in Fig. 2, even if that is achieved, the reaction of hydrogen and oxygen back to water is trivial compared with splitting. Thus, although there are a number of reports of water splitting using complex mixes of inorganic materials [5–12], or separated production of the two gases by use of membranes, true yields are usually low or unsustainable in the absence of other additives or a driving voltage. One way around this problem is not to produce oxygen at all, but rather to capture it with some sacrificial material (often called a hole scavenger) before it can react with the hydrogen. Here I report work on the use of certain organics as such scavengers.

3 Electronic Transitions in Titania

The approach to storing sunlight to enable water splitting has been to utilize solid state chemistry and the properties of semiconductors. This is because sunlight can excite a ground state electron across the band gap and thereby store energy which may be used to split water. Although many such materials have been made and utilized a crucial factor in application is the photo-hydro-stability of the material. For example, CdS could be a much better material for water splitting because it has a band gap in the visible (~2.4 eV), but it oxidises in the presence of water and light [13] and the band positions are not properly aligned for water splitting. Titania has been shown to be generally photo-hydrostable and so is the focus here, but it is worth noting that other, less stable semiconductors have been proposed for use when coated with a fairly thick layer of titania for protection [14].

There is much discussion of which morphology of titania is best for photocatalysis, with general agreement that anatase is better than rutile. In some ways this is surprising because rutile has the smaller bandgap (3.0 vs 3.2 eV). However, there are two factors which militate against rutile:

-

(i)

It has a direct bandgap, which results in a shorter lifetime of the e–h pair than in anatase [15, 16], and

-

(ii)

Rutile is usually a low surface area material.

However, a number of workers [17–19] claim that a mix of the two morphologies gives higher yields than either individually due to positive interfacial effects between the two, and indeed the material often used as choice for the reaction is commercially available P25 TiO2, which is an approximately 4:1 mix of anatase and rutile. A number of reasons have been postulated for the advantage of the mixture, the most obvious perhaps being that excitation can occur in anatase, but excited electrons transfer to the rutile, extending the lifetime if the e–h pair significantly.

Nonetheless the picture is not as simple as this—some anatase titanias perform better than P25 for the reactions described and rutile titania can be a good catalyst under the right conditions.

4 Reactivity of Titania Under Anaerobic Conditions

Notwithstanding our discussion in the section above, the reactivity of titania alone is low in the absence of gas phase oxygen. In the presence of oxygen it is widely applied for the demineralisation of water, and in academic studies for the decolouration of dyes, but in terms of the hydrogen production we are discussing in this paper, it is important to note that it has good activity for recombining oxygen and hydrogen [4]. Hence it is essential to carry out hydrogen production in an anaerobic environment, but is also important to note that titania is very inactive for hydrogen producing reactions by reforming of simple organics, such as methanol. There is some activity, but it is very much lower than the activity of the metal-loaded catalysts described below under the same conditions.

5 The Specifics: Reactivity

Figure 3 shows hydrogen evolution rates for Pt/TiO2 catalysts for several different loadings. The rate is low at low and high metal loadings and is maximized in between at ~0.1 wt%, and previous results for Pd are also shown here [20–22]. Both the Pd and Pt produce similar peak rates, with Pt having the higher rate, though Pd appears to perform better at very low loadings of metal. Such reactivity is sustained and the catalyst can be taken out from the reactor and re-used with the same hydrogen production rate. It appears to be very robust, at least when used at ambient temperatures. Similarly Au based catalysts also show a maximum, but with lower peak rate which occurs at higher loadings [23, 24].

6 Why Metal is Important for Steady State Photocatalysis

For most of the reactions involved (for example methanol reforming with water) addition of metal to the surface of titania enormously improves the hydrogen yield, as shown above. So why is this? What is the role of the metal? There are a number of roles that have been proposed in the literature. One is that the metal acts to improve the lifetime of the electron–hole pair by trapping the itinerant electron [17–19]. Another is that the metal is essential for the initial steps of the photocatalysis, that is, the reaction of the organic with the surface, usually involving dehydrogenation/decarbonylation reactions [25, 26]. Similarly, Joo et al. recently dismissed the role of the metal as a centre for electron trapping and also postulated that the metal plays an important chemical role, that is, as a centre for hydrogen atom recombination [27]. Such reactions are much easier on precious metals than on titania. So, for instance, methanol and other oxygenates simply decarbonylate on pure Pd to CO and H2, even at room temperature [25, 26, 28], whereas on titania it follows a much more complex and energetically demanding route, involving dehydration and dehydrogenation reactions, occuring above 600 K [29, 30].

The reaction pathway is summarized in Figs. 4 and 5 and there are a number of chemical steps involved in the catalytic process. Firstly the methanol has to adsorb on the surface of the metal, where it decarbonylates to adsorbed CO and gas phase hydrogen. That this occurs at ambient temperature is proved by experiments on pure Pd in single crystal form. Methanol adsorbs, giving off hydrogen and stops once the surface is saturated with CO [31]. This is the situation before light hits the titania support and at that point no further reaction can take place due to this self-poisoning by adsorbed CO. However, light of wavelength shorter than the bandgap of titania causes e–h pair formation. The hole is highly electrophilic O−, and, by the principal of Ockham’s Razor, and in the absence of any other evidence of the nature of the oxidising species, it is that O− which attacks CO adsorbed on the Pd, producing CO2 and liberating a free site on the Pd for further methanol adsorption. What is left then is an anion vacancy on the titania support, which, it is proposed, is filled by water, liberating another mole of hydrogen and completing the catalytic cycle in Fig. 5. The oxygen from that water is not released, but fills the anion vacancy. So this is summarized in the following reaction scheme:

Reactions steps proposed for methanol photo-reforming on Pd/TiO2. 1, methanol adsorption and dehydrogenation at a vacant site on the Pd nanoparticle. Without light the reaction stops due to self-poisoning of the surface by CO. 2, band gap excitation forming an electron–hole pair, with hole attack on the adsorbed CO, which results in 3, the desorption of CO2 and the creation of a free site on the metal (V) and an anion vacancy (V 2−o ) in the oxide. The vacancy is then filled by water. 4, with the release of a further mole of hydrogen and completion of the photocatalytic cycle, 5

Overall

Thus the importance of the presence of the metal is principally a catalytic one—it is more efficient than an oxide like titania in carrying out ambient temperature decarbonylation/dehydrogenation. It is not only Pd and Pt that can do this—all noble metals can do it to different degrees [3, 4, 24]. The main requirement is that those metals that are active for the reaction are easily photo-reduced by methanol at ambient conditions in an exothermic fashion, that is:

in this case the stoichiometry is for the case of simple divalent oxides. In the case of Pd the thermodynamics are favourable (ΔH = −156 kJ/mol). In principal it is likely that any metal can work. Ni and Fe do not work for the reaction, simply because they cannot be reduced in the reaction mixture.

7 Substrate Structure Effects

Although so far in this article we have focused on methanol, a range of other molecules work for the reactions, and just a few examples are show in Fig. 6. A range of primary and secondary alcohols and polyols work, aldehydes work, and Fig. 6 also shows results for two amines, and a range of amines work. Ketones and acids do not work, the primary reason being the requirement for an H to be available on the C atom adjacent to the functional group. Longer chain alcohols produce alkanes as co-products together with hydrogen and CO2 (e.g. ethane with propan-1-ol), and the general reaction formula seems to be: \({\text{RCH}}_{ 2} {\text{OH}} + {\text{H}}_{ 2} {\text{O}} + {\text{hv}} \to {\text{CO}}_{ 2} + {\text{RH}} + 2 {\text{H}}_{ 2}\).

8 CO2 Production

In terms of what has been described above there should be CO2 produced from the reaction, and indeed there is. However Fig. 7 shows two results from a reaction in solution and two from the gas phase and it can be seen that there are very different ratios of H2:CO2 observed than might be expected according to the formula (1) above. This deficiency in CO2 production has also been noted previously by Sakata and Kawai [32]. However, this is simply because of the high solubility of CO2 in water due to carbonic acid and carbonate formation. In the case of the liquid phase reaction 100 ml of water was used in the mix with the catalysts and 0.1 ml of methanol, whereas in the other case the catalyst is suspended above a much smaller amount of water, so that dissolution of the CO2 is much reduced and the ratio of CO2 to hydrogen is close to that expected when the water level is very low.

9 So What? The Photocatalytic Window

We have now learned much about photocatalytic hydrogen production, so can we put it into practical use? The movie in the supplementary data shows a simple system in the author’s back garden in Oxfordshire UK (latitude 51°35′ N). Here we used a catalyst (1 % Pd/TiO2) contained in a Pyrex test tube with a layer of the catalyst at the bottom (exposing ~3 cm2 of catalyst geometrical surface to natural sunlight, about 0.3 g of catalyst). Having no pure ethanol available, gin (Gordon’s London Dry Gin) was used (diluted 10:1 with distilled water). The catalyst is clearly producing gas bubbles, which from previous experiments [3, 33] will be mostly H2, CH4 and some CO2. The catalyst continued to operate over a period of a month until stopped, and on a completely sunny day in June produced gas at an average rate of ~0.3 ml per hour between 10 am and 6 pm. With this practical example then, we envisage that a panel of 1 m2 would produce very approximately 1 dm3 of gas per hour, and probably significantly more with much improved design features compared with the simple example here. It is possible that such gas could be used for domestic combustion and cooking. But what would such a system look like? A proposed set-up is shown schematically in Fig. 8. Here we have a storage system for the reactant liquor, the liquid passes over the flat bed panel consisting of a UV transmitting material (note that in our experiments we do not use quartz and usually use borosilicate glass) and a back plate which is coated with catalyst. This could then operate either as a window or a panel. However, if operating as a window, obviously it would not be achieving its maximum potential since it needs to transmit a large proportion of the light. Further, in separate experiments we have found that maximum hydrogen production is only achieved when a layer ~0.2 mm thick [34] is applied to the glass, which then absorbs/scatters most of the light. The gas produced from the panel passes through to a storage device which could either be batch storage or could be directly connected to the cooker.

Besides use in this way such a device may be more appropriately applied in communities in the world who have exhausted wood supplies for cooking and don’t have easy access to fossil fuels, but who have high sunlight levels. It is likely that they can ferment alcohol products which could then be used to generate useable gas, particularly appropriate, perhaps, in communities where consumption of the alcohol is forbidden!

Of course, much of this is surmise at present and such a device has not yet been produced. It is feasible, but for domestic application safety is of major concern, and storage/monitorring/control of the gas would have to be arranged most carefully.

References

McKay DJC (2008) ‘Sustainable energy—without the hot air’ UIT Cambridge, and www.withouthotair.com

Lan R, Irvine JTS, Tao S (2012) Int J Hydrog Energy 37:1482

Bowker M (2012) Catal Lett 142:923

Bowker M (2011) Green Chem 13:2235

Takanabe K, Domen K (2012) ChemCatChem 4:1485

Rocheleau RE, Miller EL, Misra A (1998) Energy Fuels 12:3

Reece SY, Hamel JA, Sung K, Jarvi TD, Esswein AJ, Pijpers JJH, Nocera DG (2011) Science 334:645

Brillet J, Yum JH, Cornuz M, Hisatomi T, Solarska R, Augustynski J, Gratzel M, Sivula K (2012) Nat Photonics 26:824

Abdi FF, Han L, Smets AHM, Zeman M, Dam B, van de Krol R (2013) Nature Commun. 4:1

Liu C, Tang J, Chen HM, Liu B, Yang P (2013) Nano Lett 13:2989

Shaner MR, Fountaine KT, Ardo S, Coridan RH, Atwater HA, Lewis N (2014) Energy Environ Sci 7:779

Maeda K, Teramura K, Lu D, Takata T, Saito N, Inoue Y, Domen K (2006) Nature 440:295

Inoue T, Watanabe T, Fujishima A, Honda K-I, Kohayakawa K (1977) J Electrochem Soc 124:719

Shu H, Shaner MR, Beardslee JA, Lichterman M, Brunschwig BS, Lewis NS (2014) Science 344:1005

Colbean-Justin C, Kunst M (2003) J Mat Sci 38:2429

Xu G, Gao Y, Moreno EM, Kunst M, Muhler M, Wang Y, Idriss H, Woll C (2011) Phys Rev Lett 106:138302

Bashir S, Wahab AK and Idriss H Catal Today, in press, http://dx.doi.org/10.1016/j.cattod.2014.05.034

Zhang J, Xu Q, Feng Z, Li M, Li C (2008) Angew Chem Int Ed 47:1766

Ozawa T, Iwasaki M, Taka H, Akita T, Tanaka K, Ito S (2005) J Colloid Interface Sci 281:510

Dickinson A, James D, Perkins N, Cassidy T, Bowker M (1999) J Mol Cat A 146:211

Bowker M, James D, Stone P, Bennett R, Perkins N, Millard L, Greaves J, Dickinson A (2003) J Catal 217:427

Al-Mazroai LS, Bowker M, Davies PR, Dickinson A, Greaves J, James D, Millard L (2007) Catal Today 122:46

Bowker M, Millard L, Greaves J, James D, Soares J (2004) Gold Bulletin 37:170

Bowker M, Morton C, Kennedy J, Bahruji H, Greaves J, Jones W, Davies PR, Brookes C, Wells PP, Dimitratos N (2014) J. Catal 10:10

Bowker M, Holroyd R, Perkins N, Gilbert L, Counsell J, Morgan C (2010) J Phys Chem C 114:17142

Bowker M, Cookson L, Bhantoo J, Carley AF, Hayden E, Gilbert L, Morgan C, Counsell J (2011) Appl Catal A 391:394

Joo JB, Dillon R, Lee I, Yin Y, Bardeen CJ, Zaera F (2014) Proc Nat Acad. Sci 111:7942

Holroyd R, Bowker M (1997) Surface Sci 377–379:786

Lusvardi VS, Barteau MA, Farneth W (1995) J Catalysis 153:41

Pringle T, Aas N, Bowker M (1994) J Chem Soc Faraday Trans 90:1015

Francis S, Corneille J, Goodman DW, Bowker M (1996) Surface Sci 364:30

Sakata T, Kawai T (1981) Chem Phys Lett 80:341

Bahruji H, Bowker M, Davies PR, Al-Mazroai L, Dickinson A, Greaves J, James D, Millard L, Pedrono FJ (2010) Photochem Photobiol A 216:115

Greaves J, Al-Mazroai L, Nuhu A, Davies PR, Bowker M (2006) Gold Bulletin 39:216

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bowker, M., Bahruji, H., Kennedy, J. et al. The Photocatalytic Window: Photo-Reforming of Organics and Water Splitting for Sustainable Hydrogen Production. Catal Lett 145, 214–219 (2015). https://doi.org/10.1007/s10562-014-1443-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1443-x