Abstract

A mean field microkinetic evaluation of previously reported DFT-derived Gibbs free energy profiles for CO and CO2 hydrogenation to methanol on Cu(111), Cu(211) and Zn-modified Cu(211) is presented. It is demonstrated that explicit consideration of the effect of surface coverages of reaction intermediates on rates is needed in order to arrive at a realistic evaluation of the activity and selectivity. In particular, both the methanol formation rate and the CO/CO2 selectivity for methanol production are demonstrated to be highly sensitive to the saturation coverage of formate at steady state. In general, the study emphasises the importance of including explicit kinetic analyses when mechanistic DFT-derived energy profiles are interpreted for catalytic processes.

Graphical Abstract

Similar content being viewed by others

Notes

See Supplementary Material for more information.

Given that experimental Cu-catalyzed MeOH synthesis selectivity is >99%, it is reasonable to assume that selectivity towards formic acid as product will not exceed 1 %. Therefore, the formic acid pressures associated with 1 % formic acid production in the kinetic runs were determined and found to be of the order of 0.28 mbar for all CO2 hydrogenation cases considered. Analysis 2 runs thus treat this formic acid pressure as a fixed kinetic model input parameter essential in ensuring the reincorporation of formic acid into the mechanism for methanol production. Furthermore, the formic acid pressure is required to be relatively low to ensure that both formic acid and methanol are produced from CO2 hydrogenation, rather than the production of CO2 and methanol from the consumption of externally introduced formic acid. From an experimental perspective this approach is regarded as a more accurate kinetic treatment of CO2 conversion via formic acid to methanol compared to Analysis 1 where no formic acid pressure build-up is allowed, artificially inhibiting the formation of methanol. Further validity of the low formic acid pressure is reflected in the similarity of kinetic data obtained in Table 2 (formally gas phase HCOOH treatment) and Table 3 (formally surface intermediate HCOOH* treatment) for the Cu(211) surface

See footnote 2

See Footnote 2

Note that for these energy profiles and microkinetic analyses no gas phase formation of formic acid is considered, but rather the formation of surface intermediate HCOOH*, effectively eliminating the possibility for formic acid to form as a product.

See Footnote 7

The 0.31 ML formate saturation coverage was calculated from the 3.4 × 1014 formates/cm2 coverage [reported by Henn FC, Rodriguez JA, Campbell CT (1990) Surf. Sci. 236:282] based on a Cu(110) (1 × 1) surface unit cell with dimensions a = 3.6147 Å and b = 2.5560 Å.

The formate saturation coverage limit is defined as the sum of the saturation coverage limit of HCOO* and HCOOH* on the surface. It is found that HCOOH* constitutes at most only 0.02 ML of the combined total coverage, effectively implying that the steady state coverage for these two species is mainly due to HCOO* on the surface. For the RPBE functional a saturation coverage limit range of 0.1–0.8 ML was considered, because it is evident from the RPBE steady state formate coverage for combined CO and CO2 hydrogenation in Table 3 that the highest coverage of 0.86 ML obtained represents an upper limit for formate coverage. Similarly, for the BEEF-vdW functional a saturation coverage limit of 0.1–0.9 ML was considered because the upper limit for formate saturation coverage approaches 0.97 ML (Table 3). See Supplementary Material for more details

The procedure, based on the methods described by (a) Saltelli A, Ratto M, Tarantola S, Campolongo F (2012) Chem. Rev. 112:PR1 and (b) Stegelmann C, Anfreasen A, Campbell CT (2009) J. Am. Chem. Soc. 131:8077, involved isolated increase of each of the seven barriers in the CO2 hydrogenation reaction sequence by 0.1 eV in each case determining the methanol formation rate at steady state. Four sets of data were obtained for each of the RPBE and BEEF-vdW determined DFT data sets at 0.5 and 1.0 ML formate saturation coverage limit, respectively

See Footnote 9

References

Lee S (1989) Methanol Synthesis Technology. CRC Press, Boca Raton

Olah GA, Goeppert A, Prakash GKS (2009) Beyond Oil and Gas: The Methanol Economy, 2nd edn. Weinheim, Wiley-VCH

Mei D, Xu L, Henkelman G (2009) J Phys Chem 313:4522

Yang Y, Evans J, Rodriguez JA, White MG, Liu P (2010) Phys Chem Chem Phys 12:9909

Chuasiripattana K, Warschkow O, Delley B, Stampfl C (2010) Surf Sci 604:1742

Zhao Y-F, Yang Y, Mims C, Peden CHF, Li J, Mei D (2011) J Catal 281:199

Yang Y, White MG, Liu P (2012) J Phys Chem C 116:248

Zhao Y-F, Rousseau R, Li J, Mei D (2012) J Phys Chem C 116:15952

Behrens M, Studt F, Kasatkin I, Kühl S, Hävecker M, Abild-Pedersen F, Zander S, Girgsdies F, Kurr P, Kniep B-L, Tovar M, Fischer RW, Nørskov JK, Schlögl R (2012) Science 336:893

Studt F, Abild-Pedersen F, Varley JB, Nørskov JK (2013) Catal Lett 143:71

Grabow LC, Mavrikakis M (2011) ACS Catal. 1:365

Studt F, Abild-Pedersen F, Wu Q, Jensen AD, Temel B, Grunwaldt J-D, Nørskov JK (2012) J Catal 293:51

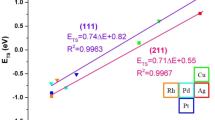

Medford AJ, Sehested J, Rossmeisl J, Chorkendorff I, Studt F, Nørskov JK, Moses PG (2014) J Catal 309:397

Studt F, Sharafutdinov I, Abild-Pedersen F, Elkjær CF, Hummelshøj JS, Dahl S, Chorkendorff I, Nørskov JK (2014) Nature Chem. doi:10.1038/NCHEM.1873

Dumesic JA, Rudd DF, Aparicio LL, Rekoske JE (1993) Trevino AA The Microkinetics of heterogeneous Catalysis. American Chemical Society, Washington, DC

Van Helden P, van den Berg J-A, Weststrate CJ (2012) ACS Catal. 2:1097

Yoshihara J, Campbell CT (1996) J Catal 161:776

Hansen JB, Nielsen PEH (2008) In: Ertl G, Knözinger H, Schüth F, Weitkamp J (eds) Handbook of heterogeneous catalysis. Wiley, Weinheim

Chinchen GC, Denny PJ, Parker DG, Spencer MS, Whan DA (1987) Appl. Catal. 30:333

Wellendorf J, Lundgaard KT, Møgelhøj A, Petzold V, Landis DD, Nørskov JK, Bligaard T, Jacobsen KW (2012) Phys. Rev. B 85:235149

Nakamura J, Kushida Y, Choi Y, Uchijima T, Fujitani T (1997) Vac Sci Technol A 15:1568

Fujitani T, Choi Y, Sano M, Kushida Y, Nakamura J (2000) J. Phys. Chem. B 104:1235

Yatsu T, Nishimura H, Fujitani T, Nakamura J (2000) J Catal 191:423

Hayden BE, Prince K, Woodruff DP, Bradshaw AM (1983) Surf Sci 133:589

Rasmussen PB, Holmblad PM, Askgaard T, Oveson CV, Stoltze P, Nørskov JK, Chorkendorff I (1994) Catal Lett 26:373

Acknowledgement

Prof Eric van Steen (University of Cape Town) is acknowledged for his inputs and proof reading of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Janse van Rensburg, W., Petersen, M.A., Datt, M.S. et al. On the Kinetic Interpretation of DFT-Derived Energy Profiles: Cu-Catalyzed Methanol Synthesis. Catal Lett 145, 559–568 (2015). https://doi.org/10.1007/s10562-014-1407-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1407-1