Abstract

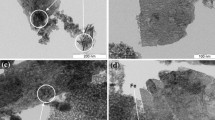

A new alumina-supported cobalt–nickel oxide catalyst for the synthesis of acetonitrile from ethanol and ammonia was prepared by coprecipitation-kneading method. The parameters influencing the reaction were studied thoroughly and an optimized process, which is running the reaction at 380 °C under atmospheric pressure while keeping the ammonia/alcohol molar ratio of 5 and GHSV of 1,163 h−1, was obtained. Under the optimized conditions the catalyst reached its best performance when being on stream for 40 h, at which the yield of acetonitrile was 92.6%. Then the selectivity to acetonitrile decreased gradually but the yield of acetonitrile always remained higher than 81% within 720 h. The samples of the fresh and used catalyst were characterized by XRD, XPS, TEM, EDX and N2 adsorption–desorption analysis. The results revealed that carbon deposition and formation of metal carbides from the active species in the catalytic runs led to the deterioration of the catalyst.

Graphical Abstract

A new Co–Ni/γ-Al2O3 catalyst for the amination of ethanol to acetonitrile was studied in a continuous fixed-bed reactor and the reaction parameters were optimized. The mechanisms for the formation of acetonitrile and butyronitrile were discussed. The reasons leading to the deterioration of the catalyst were investigated through the characterization of the fresh, used and regenerated samples of the catalyst by means of XRD, XPS, TEM and N2 adsorption–desorption techniques.

Similar content being viewed by others

References

Iida S, Togo H (2007) Tetrahedron 63:8274

Grasselli RK, Callahan JL (1969) J Catal 14:93

Andersson A, Andersson SLT, Centi G, Grasselli RK, Sanati M, Trifiro F (1993) Stud Surf Sci Catal 75:691

Potaraju R, Vishnu JM (1986) EP Patent 0,206,632, Indian Explosives Limited, ICI

Olivé G, Olivé S (1979) US Patent 4,179,462, Monsanto Company, St. Louis, MO

Hummel AA, Badani MV, Hummel KE, Delgass WN (1993) J Catal 139:392

Eshelman LM, Delgass WN (1994) Catal Today 21:229

Badani MV, Eshelman LM, Delgass WN (1993) Stud Surf Sci Catal 75:1223

Sandner WJ, Fierce WL (1961) CA Patent 615,929, Pure Oil Company

Fierce WL, Lake C, Sandner WJ (1957) US Patent 2,802,020, Pure Oil Company

Krebaum LJ (1964) US Patent 3,129,241, Monsanto Chemical Company, St. Louis, MO

Fierce WL, Sandner WJ (1959) CA Patent 586,008, Pure Oil Company

Fierce WL, Lake C, Sandner WJ (1962) US Patent 3,056,826, Pure Oil Company

Morikawa K, Shiba T (1961) GB Patent 870,462A, State of Japan

Callahan JL, Stamm JA (1963) US Patent 3,106,574, Standard Oil Company

Stamm JA, Callahan JL (1965) CA Patent 718,939A, Standard Oil Company

Zhang HT, Zhang YN, Chen J (2005) CN Patent 1,226,281C, Zhang HT

Reddy BM, Manchar B (1993) J Chem Soc Chem Commun 3:234

Kulkarni SJ, Ramachandra Rao R, Subrahmanyam M, Rama Rao AV (1994) J Chem Soc Chem Commun 3:273

Roger JC, Lawrence JS (1981) J Org Chem 46:754

Zhang YN, Zhang YC, Feng C, Qiu CJ, Wen YL, Zhao JQ (2009) Catal Commun 10:1454

Kurina LN, Golovko AK, Galanov SI, Sidorova OI (2003) RU Patent 2,214,396C2, Inst Khim Nefit So Ran

Hou XM, Yan L, Zhang X, Li YW, Li CB (2009) J Jilin Norm Univ (Nat Sci Ed) 30:108

Kryukov YB, Bashkirov AN, Zakirov NS, Novak FL (1966) Dokl Akad Nauk SSSR 170:852

Pan WX (1992) CN Patent 1,062,303, Tsinghua University

Kulkarni SJ, Ramachandra Rao R, Subrahmanyam M, Rama Rao AV (1994) Appl Catal A 113:1

Kumar RJ, Joshi PN, Chapekar GM (2005) WO Patent 2,005,000,816A, Council of Scientific and Industrial Research, Jubilant Organosys Ltd

Rausch AK, van Steen E, Roessner F (2008) J Catal 253:111

Neylon MK, Bej SK, Bennett CA, Thompson LT (2002) Appl Catal A 232:13

Higashio YS, Shoji T (2004) Appl Catal A 260:251

Ramachandra Rao R, Srinivas N, Kulkarni SJ, Subrahmanyam M, Raghavan KV (1997) Appl Catal A 161:L37

Jin F, Cui YG, Li YD (2008) Appl Catal A 350:71

Volckmar CE, Bron M, Bentrup U, Martin A, Claus P (2009) J Catal 261:1

Barthos R, Solymosi F (2005) J Catal 235:60

Modrogan E, Valkenberg MH, Hoelderich WF (2009) J Catal 261:177

Freire RM, de Sousa FF, Pinheiro AL, Longhinotti E, Mendes Filho J, Oliveira AC, de Tarso C, Freire P, Ayala AP, Oliveira AC (2009) Appl Catal A 359:165

Martin A, Narayana Kalevaru V, Lücke B, Brückner A (2008) Appl Catal A 335:196

Wang HF, Chen LG, Bai GY, Luan DZ, Li Y, Yan XL, Zhang YC, Xing JD (2007) Catal Commun 8:145

Seehra MS, Dutta P, Manivannan A (2005) Div Fuel Chem 50:638

Tavasoli A, Malek Abbaslou RM, Dalai AK (2008) Appl Catal A 346:58

Zhang DS, Shi LY, Fang JH, Li XK, Dai K (2005) Mater Lett 59:4044

Ruckenstein E, Wang HY (2002) J Catal 205:289

Wang ZH, Choi CJ, Kim BK, Kim JC, Zhang ZD (2003) Carbon 41:1751

Bechara R, Balloy D, Vanhove D (2001) Appl Catal A 207:343

Waldrop JR, Grant RW (1990) Appl Phys Lett 56:557

Kuivila CS, Butt JB, Stair PC (1988) Appl Surf Sci 32:99

Sinharoy S, Levenson LL (1978) Thin Solid Films 53:31

Ramqvist L, Hamrin K, Johansson G, Fahlman A, Nordling C (1969) J Phys Chem Solids 30:1835

Li CP, Proctor A, Hercules DM (1984) Appl Spectrosc 38:880

Wang ZH, Zhang ZD, Choi CJ, Kim BK (2003) J Alloys Compd 361:289

Nieto-Márquez A, Valverde JL, Keane MA (2009) Appl Catal A 352:159

Alfred GC, Yardley P, Partha SG, Princeton NJ (1991) US Patent 5,037,791, HRI, Inc

Hu ZH, Guo HM, Srinivasan MP, Yaming N (2003) Sep Purif Technol 31:47

Hu ZH, Srinivasan MP (2001) Microporous Mesoporous Mater 43:267

Inagaki M, Radovic LR (2002) Carbon 40:2279

Acknowledgments

We thank the financial support by the National Natural Science Foundation of China (Grant no. 20976034) and the Natural Science Foundation for Young Scientists of Hebei Province, China (Grant no. B2009000009) and Guide Project for the Development of Science and Technology of Hebei Province, China (Grant no. 072156136).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, C., Zhang, Y., Zhang, Y. et al. Study on Alumina-Supported Cobalt–Nickel Oxide Catalyst for Synthesis of Acetonitrile from Ethanol. Catal Lett 141, 168–177 (2011). https://doi.org/10.1007/s10562-010-0468-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0468-z