Abstract

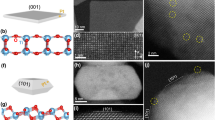

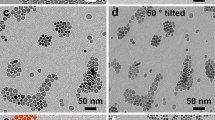

We demonstrate a technique to prepare high surface area ZnO powders that preferentially favor a plate-like morphology, exposing the \((0001)/(000\bar{1})\) facets. A solution-based synthetic route was used to decompose zinc acetate in the presence of amine and citrate ions to block the \((0001)/(000\bar{1})\) facets and favor growth from the pyramid planes. The ZnO platelets remained stable upon heating to 250 °C as evidenced by electron diffraction patterns. The high surface area (75 m2/g) and surface energetics of the (0001) plane make these powders suitable as supports for heterogeneous catalysts.

Graphical Abstract

Similar content being viewed by others

References

Vesborg PCK, Chorkendorff I, Knudsen I, Balmes O, Nerlov J, Molenbroek AM, Clausen BS, Helveg S (2009) J Catal 262(1):65. doi:10.1016/j.jcat.2008.11.028

Iwasa N, Takezawa N (2003). Top Catal V22(3):215. doi:10.1023/A:1023571819211

Karim AM, Conant T, Datye AK (2008) Phys Chem Chem Phys 10:5584. doi:10.1039/b800009c

Cheng WH, Akhter S, Kung HH (1983) J Catal 82(2):341. doi:10.1016/0021-9517(83)90200-2

Wilmer H, Kurtz M, Klementiev KV, Tkachenko OP, Grünert W, Hinrichsen O, Birkner A, Rabe S, Merz K, Driess M, Wöll C, Muhler M (2003) Phys Chem Chem Phys 5:4736. doi:10.1039/b304425d

Vohs J, Barteau M (1986) Surf Sci 176(1–2):91. doi:10.1016/0039-6028(86)90165-2

Hyman MP, Lebarbier VM, Wang Y, Datye AK, Vohs JM (2009) J Phys Chem C 113(17):7251. doi:10.1021/jp809934f

Bowker M, Houghton H, Waugh KC (1981) J Chem Soc Faraday Trans 1: Phys Chem Condens Phases 77:3023. doi:10.1039/F19817703023

Halevi B, Vohs JM (2005) J Phys Chem B 109(50):23976

Diebold U, Koplitz LV, Dulub O (2004) Appl Surf Sci 237(1–4):336

Dulub O, Boatner LA, Diebold U (2002) Surf Sci 519(3):201

Ada K, Gökgöz M, Önal M, Sarıkaya Y (2008) Powder Technol 181(3):285. doi:10.1016/j.powtec.2007.05.015

Li GR, Hu T, Pan GL, Yan TY, Gao XP, Zhu HY (2008) J Phys Chem C 112(31):11859. doi:10.1021/jp8038626

Xu CX, Sun XW, Dong ZL, Yu MB (2004) Appl Phys Lett 85(17):3878. doi:10.1063/1.1811380

Wang F, Liu R, Pan A, Cao L, Cheng K, Xue B, Wang G, Meng Q, Li J, Li Q, Wang Y, Wang T, Zou B (2007) Mater Lett 61(10):2000. doi:10.1016/j.matlet.2006.08.007

Staemmler V, Fink K, Meyer B, Marx D, Kunat M, Girol SG, Burghaus U, Wöll C (2003) Phys Rev Lett 90(10):106102/1

Yu Q, Yu C, Yang H, Fu W, Chang L, Xu J, Wei R, Li H, Zhu H, Li M, Zou G, Wang G, Shao C, Liu Y (2007) Inorg Chem 46(15):6204. doi:10.1021/ic070008a

Wang M, Hahn SH, Kim JS, Chung JS, Kim EJ, Koo KK (2008) J Cryst Growth 310(6):1213. doi:10.1016/j.jcrysgro.2008.01.001

Tian ZR, Voigt JA, Liu J, McKenzie B, McDermott MJ, Rodriguez MA, Konishi H, Xu H (2003) Nat Mater 2(12):821. doi:10.1038/nmat1014

Rietveld HM (1969) J Appl Crystallogr 2(2):65. doi:10.1107/S0021889869006558

Larson AC, Dreele RBV (2004) General structure analysis system (GSAS). Technical report, Los Alamos National Laboratory Report LAUR 86-748

Toby BH (2001) J Appl Crystallogr 34(2):210 doi:10.1107/S0021889801002242

Downs RT, Hall-Wallace M (2003) . Am Mineral 88:247

Brunauer S, Emmett PH, Teller E (1938) J Am Chem Soc 60(2):309

Cho S, Jang JW, Jung SH, Lee BR, Oh E, Lee KH (2009) Langmuir 25(6):3825. doi:10.1021/la804009g

Chippindale AM, Hibble SJ, Bilbé EJ (2009) Acta Crystallogr Sect C 65(7):i39. doi:10.1107/S0108270109020885. http://dx.doi.org/10.1107/S0108270109020885

Abràmoff MD, Magalhães PJ, Ram SJ (2004) Biophotonics Int 11(7):36

Cao X, Zeng H, Wang M, Xu X, Fang M, Ji S, Zhang L (2008) J Phys Chem C 112(14):5267. doi:10.1021/jp800499r

Acknowledgements

This work has been supported by the United States Department of Energy Office of Basic Energy Science, Division of Chemical Sciences under contract number DE-FG02-05ER15712 (University of New Mexico), and DE-AC0494AL85000 (Sandia National Laboratories), Division of Material Science. Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company for the United States Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Burton, P.D., Peterson, E.J., Boyle, T.J. et al. Synthesis of High Surface Area ZnO(0001) Plates as Novel Oxide Supports for Heterogeneous Catalysts. Catal Lett 139, 26–32 (2010). https://doi.org/10.1007/s10562-010-0405-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0405-1