Abstract

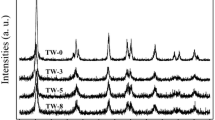

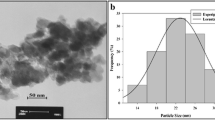

A composite oxide ZnAl2O4 was prepared by microwave-assisted hydrothermal treatment, a precursor mixture of hydroxides obtained by precipitation of aluminium and zinc nitrates. Characterization by TEM, XRD and textural studies shows that ZnAl2O4 is nanosized and is a micro/mesoporous material with large a surface area (140 m2/g). The gas phase catalytic methylation of 4-hydroxypyridine in the presence of the ZnAl2O4 catalyst was performed in a continuous process at atmospheric pressure in the temperature range of 240–360 °C. A mixture of O- and N-alkylated products, namely 4-methoxypyridine and N-methyl-4-pyridone were obtained. The alkylation of 4-hydroxypyridine with methanol at 345 °C offered 87.6% selectivity towards N-methyl-4-pyridone with about 89% 4-hydroxypyridine conversion.

Similar content being viewed by others

References

Electronic Medicines Compendium http://emc.medicines.org.uk/emc/assets/c/html/DisplayDoc.asp?DocumentID=6380

Stetinova V, Grossmann V (2000) Exp Toxicol Pathol 52:473

Dyer DJ, Lee VY, Twieg RJ (1997) Liquid Cryst 23:551

You F, Twieg RJ (1999) Tetrahedron Lett 40:8759

Gibson D, Clarke D, Winscom Ch (2000) US Pat 6,841,344

Grabowska H, Zawadzki M, Syper L (2006) Appl Catal A: Gen 314:226

Komarneni S, Katsuki H (2002) Pure Appl Chem 74:1537

Rao KJ, Mahesh K, Kumar S (2005) Bull Mater Sci 28:19

Malinger KA, Laubernds K, Son YC, Suib SL (2004) Chem Mater 16:4296

Ren ZW, Zhou DB, Tu SQ (2007) Chin J Catal 8:217

International Centre for Diffraction Date, ICDD, PDF-4 + 2005

Dollimore D, Heal GR (1964) J Appl Chem 14:109

Wrzyszcz J, Zawadzki M, Trawczyński J, Grabowska H, Miśta W (2001) Appl Catal A: Gen 210:263

Grabowska H, Miśta W, Trawczyński J, Wrzyszcz J, Zawadzki M (2001) Appl Catal A: Gen 220:207

Grabowska H, Zawadzki M, Syper L, Miśta W (2005) Appl Catal A: Gen 292:208

Sparks AK (1972) US Patent 3,670,030

Leach BE (1980) US Patent 4,227,024

IUPAC Recommendations (1994) Pure Appl Chem 66:1739

Di Cosimo JI, Diez VK, Xu M, Iglesia E, Apesteguia CR (1998) J Catal 178:499

Di Cosimo JI, Apesteguia CR, Gines MJL, Iglesia E (2000) J Catal 190:261

Beak P, Bonham J, Lee TJ Jr (1968) J Am Chem Soc 90:1569

Acknowledgments

The authors are very grateful to Mrs Ludwina Krajczyk for HRTEM studies and to Prof. Janusz Trawczyński for his help in acidity measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grabowska, H., Zawadzki, M. & Syper, L. Catalytic Method for N-Methyl-4-pyridone Synthesis in the Presence of ZnAl2O4 . Catal Lett 121, 103–110 (2008). https://doi.org/10.1007/s10562-007-9305-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-007-9305-4