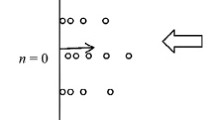

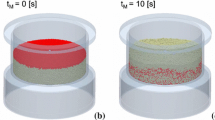

The process of mixing of a diffusing powdery material adjoining an absorbing wall moving in a specific manner is investigated. An entropy method based on statistical approach to the mixing process modeling problem is used as the mathematical apparatus. Given the statistical nature of the investigated phenomenon, an expression based on the postulates of the probability theory is obtained for the key process efficiency parameter (inhomogeneity coefficient) as a function of the parameters of this process. A method for determining the macrodiffusion coefficient that characterizes the particles mixing process intensity is proposed.

Similar content being viewed by others

References

V. V. Kafarov, Cybernetic Methods in Chemistry and Chemical Engineering [in Russian], Khimiya, Moscow (1985).

L. T. Fan, Y. M. Chen, and F. S. Lai, “Recent developments in solids mixing,” Powder Technology, 61, 255–287 (1990).

E. A. Barantseva, V. E. Mizonov, S. V. Fedosov, and Yu. V. Khoklova, “A mathematical model of kinetics of blade mixing of bulk materials,” Stroitel. Mater., No. 2, 12–13 (2008).

E. A. Barantseva, V. E. Mizonov, and Yu. V. Khoklova, “Distribution of time of bulk material particles residence in batch blade mixer,” Khim. Prom. Segodnya, No. 3, 50–53 (2009).

Y. Naumenko, “Modeling a flow pattern of the granular fill in the cross section of a rotating chamber,” Eastern-European Journal of Enterprise Technologies, 5, No. 1 (89), 59–69 (2017).

S. N. Cherpitskii, M. Y. Tirshis, L. V. Korolev, and A. V. Kapranova, “An investigation of the process of mixing of bulk materials in a drum-blade mixer,” Khim. Neftegaz. Mashinostr., No. 1, 3–6 (2020).

C. Gardiner, Stochastic Methods in Natural Sciences [Russian translation], Mir, Moscow (1986).

N. A. Fuchs, Mechanics of Aerosols [in Russian], Izd. Akad. Nauk SSSR, Moscow (1955).

V. P. Maikov, Entropy Methods of Modeling in Chemical Engineering [in Russian], MIKhM, Moscow (1981).

E. T. Jaynes, “Principle of maximum entropy,” Maximum-Entropy and Bayesian Methods in Applied Statistics, Cambridge University Press, Cambridge (1996).

E. V. Semenov, A. A. Slavyanskii, I. A. Nikitin, et al., “Calculation of finely dispersed powder mixing process,” Khim. Neftegaz. Mashinostr., No. 3, 3–6 (2020).

I. N. Bronshtein and K. A. Semendyaev, A Handbook of Mathematics for Engineers and Students of Higher Technical Educational Institutions [in Russian], Nauka, Moscow (1986).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 56, No. 10, pp. 3–6, October, 2020.

Rights and permissions

About this article

Cite this article

Semenov, E.V., Slavyanskii, A.A., Nikitin, I.A. et al. Calculation of Bulk Materials Mixing Process. Chem Petrol Eng 56, 779–786 (2021). https://doi.org/10.1007/s10556-021-00842-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-021-00842-y