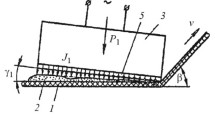

The basic techniques of computer-aided 3D variant design of an ultrasonic device based on a proposed technique of structuro-parametric simulation of a dosing cavitation device with rectangular radiative plate are described. The proposed approach assures effective determination of the required rational dimensions of the radiative plates and ultrasonic vibrators to optimize their features when employed in specific technological processes, in particular, ultrasonic cavitation dosing in the technology employed in the manufacture of composite fibrous materials.

Similar content being viewed by others

References

A. E. Kolosov, G. A. Virchenko, E. P. Kolosova, and G. I. Virchenko, “Structural and technological design of ways for preparing reactoplastic composite fibrous materials based on structural parametric modeling,” Chemical and Petroleum Engineering, 51, I, 7–8, 493–500 (2015).

A. E. Kolosov, V. I. Sivetskii, E. P. Kolosova, and E. A. Lugovskaya, “Procedure for analysis of ultrasonic cavitator with radiative plate,” Chemical and Petroleum Engineering, 48, I, 11–12, 662–672 (2013).

A. E. Kolosov, G. A. Virchenko, E. P. Kolosova, and S. L. Shambina, “Simulation of the parameters of an ultrasonic dosing cavitation device with radiative plate. Part 1: Analysis of the effective ultrasonic hardware components and a technique of structuroparametric design,” Khimicheskoe i Neftegazovoe Mashinostroenie, No. 7, 43−48 (2018).

G. A. Virchenko, A. E. Kolosov, E. P. Kolosova, and G. A. Virchenko, “Simulation of the parameters of an ultrasonic dosing cavitation device with radiative plate. Part 2: Optimization of structuro-parameters,” Khimicheskoe i Neftegazovoe Mashinostroenie, No. 8, 41−45 (2018).

D. Kymabé, Vibrational Cutting [in Russian], Mashinostroenie, Moscow (1985).

A. E. Kolosov, “Effect of low-frequency ultrasonic treatment regimes on reactoplastic polymer composite material operating properties,” Chemical and Petroleum Engineering, 50, I, 3–4, 150–155 (2014).

A. E. Kolosov, “Low-frequency ultrasonic treatment as an effective method for modifying liquid reactoplastic media,” Chemical and Petroleum Engineering, 50, I, 1–2, 79–83 (2014).

A. E. Kolosov, “Efficiency of liquid reactoplastic composite heterofrequency ultrasonic treatment,” Chemical and Petroleum Engineering, 50, I, 3–4, 268–272 (2014).

A. E. Kolosov, “Low-frequency ultrasonic treatment of liquid reactoplastic media with pressure variation,” Chemical and Petroleum Engineering, 50, I, 5–6, 339–342 (2014).

A. E. Kolosov, “Prequisites for using ultrasonic treatment for intensifying production of polymer composite materials,” Chemical and Petroleum Engineering, 50, I, 1–2, 11–17 (2014).

A. E. Kolosov, A. S. Sakharov, V. I. Sivetskii, et al., “Substantiation of the efficiency of using ultrasonic modification as a basis of a production cycle for preparing reinforced objects of epoxy polymer composition,” Chemical and Petroleum Engineering, 48, I, 5–6, 391–397 (2012).

O. G. Tsyplakov, Scientific Foundations of the Technology of Composite Fibrous materials. Part 1 [in Russian], Perm’ (1974).

H. I. Virchenko, O. O. Golova, O. P. Kolosova, and S. L. Shambina, “The use of structuro-parametric geometric models for variant design of compound acoustic concentrators,” Vestnik KhNTU, No. 3 (54), 547–550 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Part 1 may be found in No. 7 (2018), pp. 43−48; Part 2 in No. 8 (2018), pp. 41−45.

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 54, No. 9, pp. 45−48, September, 2018.

Rights and permissions

About this article

Cite this article

Vanin, V.V., Virchenko, G.A., Kolosov, A.E. et al. Simulation of the Parameters of Ultrasonic Dosing Cavitation Device with Radiative Plate. Part 3. Computer-Aided Variant 3D Design. Chem Petrol Eng 54, 694–700 (2019). https://doi.org/10.1007/s10556-019-00535-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-019-00535-7