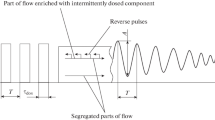

The results of experimental and analytical studies of the technological characteristics of a drum mixer for particulate solids equipped with a device for control of segregated flows of non-uniform particles is described. Analysis of the smoothing ability of the mixer was conducted in the course of continuous mixing with micro-dosed portions of one of the components. It was found that under the action of counter pulses applied to the segregated flow enriched with portions of the dosed component there is a sharp increase in the selective smoothing ability of the mixer with respect to this component of the mixture. The effect of smoothing by selective action of counter pulses on the segregated process flow is many times greater than a similar effect achieved by traditional methods such as the intensification of longitudinal mixing and increase in the working volume of the mixer.

Similar content being viewed by others

References

J. C. Williams, in: Mixing: Theory and Practice, V. W. Uhl (ed.), Academic Press, Inc., Orlando, Florida (1986).

S. V. Pershina, V. F. Pershin, and P. M. Yavnik, “The implementation of the two-step method for continuous dosing of particulate materials using a belt conveyor,” Vopr. Sovr. Nauki i Prakt., Taurida National Univ., 4, No. 42, 340–344 (2012).

V. N. Dolgunin, O. O. Ivanov, A. A. Ukolov, and A. N. Kudi, “Processing processes of particulate materials in controlled segregated flows,” Teor. Osn. Khim. Tekhnol., 48, No. 4, 434–443 (2014).

L. Bates, User Guide to Segregation, British Materials Handling Board, Elsinore House, United Kingdom (1997).

V. N. Dolgunin and O. O. Ivanov, The Processes and Equipment for the Processing of Particulate Materials under Controlled Segregated Flows, Izd. TGTU, Tambov (2011).

O. O. Ivanov, V. Ya. Borschev, and V. N. Dolgunin, “The effect of separating the particles in a drum packing machine batch,” Khim. Neftegaz. Mashinostr., 9, 13–15 (2009).

N. P. Vershinina, Investigation of the Effect of Longitudinal Mixing of the Material on the Duration of Drying It in a Tumble Dryer: Auth. Abstr. Dissert. Cand. Techn. Sci., Kharkov (1975).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 6, pp. 20–24, June, 2016.

Rights and permissions

About this article

Cite this article

Dolgunin, V.N., Ukolov, A.A., Ivanov, O.O. et al. Evaluation of the Effectiveness of a Drum Mixer for Continuous Mixing of Particulate Solids with Batch Micro-Dosing of Components. Chem Petrol Eng 52, 398–404 (2016). https://doi.org/10.1007/s10556-016-0206-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-016-0206-5