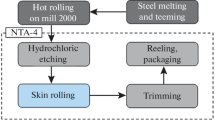

Use of a new device UDGZ-200 is considered for surface hardening. Its use increases the service life of body components, gear connections, crane wheels and rails, dies, etc., due to a marked reduction in machine and equipment down time. Its introduction does not require workshop modernization: it is capable of compensating for a lack of traditional heat treatment equipment.

Similar content being viewed by others

References

V. A. Korotkov, S. P. Ananiev, and A. V. Shekurov, “Study of the effect of cooling rate on surface layer quality with plasma hardening,” Svar. Proizvod., No. 3, 23–27 (2012).

S. P. Ananiev, V. A. Korotkov, and V. V. Kozlov, “Study of crane rail and wheel material wear resistance,” Vestn. Mashinostr., No. 8, 35–37 (2011).

M. V. Zlokazov, “Use of plasma hardening for die tool strengthening,” Remont. Vosstanovl., Moderniz., No. 2, 10–14 (2006).

V. A. Korotkov, A.V. Shekurov, D. S. Babailov, et al., “Cast iron die plasma hardening,” Remont. Vosstanovl., Moderniz., No. 1, 31–34 (2007).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 11, pp. 43–45, November, 2012.

Rights and permissions

About this article

Cite this article

Korotkov, V.A. Surface hardening equipment. Chem Petrol Eng 48, 705–708 (2013). https://doi.org/10.1007/s10556-013-9684-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-013-9684-x