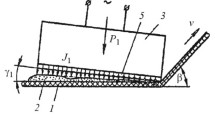

Analytical peculiarities of ultrasonic cavitators based on piezoceramic transducers with a radiative plate, which experiences bending vibrations, are analyzed. The acoustic dimensions of components of a sectional piezoelectric transducer used in the production process of contact ultrasonic treatment of a dry 1,120-mm wide cloth impregnated with a polymeric binder, are calculated.

Similar content being viewed by others

References

A. E. Kolosov, V. D. Konev, V. G. Ogonkov, et al., USSR Author’s Certificate No. 1781054, IPC B 29 B 15/12, “Method of impregnating and metering build-up of binder on a long-fiber material,” publ. Dec. 15, 1992, Byull., No. 46.

V. V. Kudryachenko, I. M. Fedotkin, and O. E. Kolosov, Ukraine Patent No. 42617A, IPC 7 B29B15/10, “Instrument for impregnation and dosed deposition of binder consisting of lengthy fibrous material,” publ. Oct. 15, 2001, Byull., No. 9.

V. V. Kudryachenko, I. M. Fedotkin, V. I. Sivetskii, et al., “Use of ultrasound in the molding of cloth polymeric composites,” Ekotekhnol. Resursosber., No. 6, 70–77 (2001).

A. F. Lugovskii, “Analysis of ultrasonic dispersers with composite piezoelectric transducers,” Vestn. Nats. Tekh. Univ. Ukrainy (Keiv Polytech. Inst.), Ser. Mashinostr., VIPOL, No. 33, 291–296 (1998).

S. P. Timoshenko, D. Kh. Yang, and W. Weaver, Vibrations in Engineering Practice [Russian translation], edited by E. I. Prigolyuk, Mashinostroenie, Moscow (1985).

A. F. Lugovskoi and A. E. Kolosov, “Procedure for analysis of an ultrasonic cavitator with a radiative plate,” Ekotekhnol. Resursosber., No. 1, 59–67 (2005).

O. E. Kolosov, V. I. Sivetskii, E. M. Panov, et al., Sidorov, Mathematical Modeling of Fundamental Processes in the Fabrication of Polymer Composite Materials with the Use of Ultrasonic Modification [in Ukrainian], VD Edelveis, Kiev (2012).

D. Kumabe, Vibrational Resonance [Russian translation], edited by I. I. Portnov and V. V. Bolov, Mashinostroenie, Moscow (1985).

D. A. Gershgal and V. M. Fridman, Ultrasonic Production Equipment [in Russian], Energiya, Moscow (1976).

K. O. Lugovska, O. E. Kolosov, V. I. Sivetskii et al., Ukraine Patent No. 57857, IPC (2009) B05C3/00, “A method of calculating the structural parameters of an ultrasonic cavitation device,” No. u201011422, subm. Sept. 24, 2010, publ. March 10, 2011, Byull., No. 5.

K. O. Lugovska, O. E. Kolosov, V. I. Sivetskii, et al., Ukraine Patent No. 57856, IPC (2009) B05C3/00, “A method of assembling and testing the functional capacity of an ultrasonic cavitation device,” No. u201011421, subm. Sept. 24, 2010, publ. March 10, 2011, Byull., No. 5.

O. E. Kolosov, V. I. Sivetskii, and K. O. Lugovska, “Techniques for calculating the structural parameters and testing the functional capacity of an ultrasonic cavitation device and special features of its patent,” Visn. NTUU KPI, Ser.Mashinobuduvannya, No. 63, 53–60 (2011).

A. V. Donskoi, O. K. Keller, and G. S. Kratysh, Ultrasonic Electrotechnical Devices [in Russian], Energoizdat, Leningrad (1982).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 11, pp. 11–17, November, 2012.

Rights and permissions

About this article

Cite this article

Kolosov, A.E., Sivetskii, V.I., Kolosova, E.P. et al. Procedure for analysis of ultrasonic cavitator with radiative plate. Chem Petrol Eng 48, 662–672 (2013). https://doi.org/10.1007/s10556-013-9677-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-013-9677-9