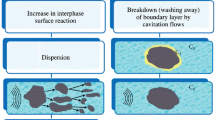

An improved method has been developed to select efficient design and operating parameters for equipment used for the ultrasonic modification of liquid-polymer composites and fibrous fillers. The method can make ultrasonic treatments more productive and speed up the processes of impregnation and batch-dosing in the molding of polymeric composites.

Similar content being viewed by others

References

B. G. Novitskii, The Use of Acoustic Vibrations in Unit Operations in Chemical Engineering [in Russian], Khimiya, Moscow (1983).

D. A. Gershgal and V. M. Fridman, Industrial Ultrasonic Equipment [in Russian], Energiya, Moscow (1976).

P. P. Prokhorenko, N. V. Dezhkunov, and G. E. Konovalov, Ultrasonic Capillary Effect [in Russian], Tekhnika, Minsk (1981).

I. P. Golyamina (ed.), Ultrasound: Concise Encyclopedia, Sov. Entsiklopediya (1979).

O. E. Sivetskii, “Technique of calculating the parameters of devices used for ultrasonic treatment and intensification of the process of impregnation of the tissues of fillers with polymer binders,” Visn. KNUTD, No. 1, 156–158 (2003).

O. E. Kolosov, “Optimization of the parameters of physical modification of epoxide oligomers and compounds based on the latter with the use of ultrasound,” Polimer. Zh., No. 2, 123–130 (2005).

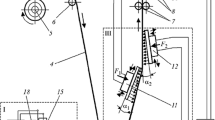

A. F. Lugovskoi and A. E. Kolosov, “Method for designing an ultrasonic cavitation unit with a radiating plate,” Ekotekhnol. Resursosber., No. 1, 59–67 (2005).

O. E. Kolosov, Molding of Polymer Composite Materials with the Use of Physicochemical Modification (in two parts). Part 1. Studies of the Prerequisites for Directed Action of Physicochemical Modification [in Ukrainian], NTUU KPI, Kiev (2005).

O. E. Kolosov and V. Sivetskii, Molding of Polymer Composite Materials with the Use of Physicochemical Modification (in two parts). Part 2. Effective Regimes and Equipment for Realization of Physicochemical Modification [in Ukrainian], NTUU KPI, Kiev (2006).

O. E. Kolosov,V. Sivetskii, and E. M. Panov, Technology for the Production of Multicomponent Epoxy Polymers with the Use of Directed Physicochemical Modification [in Ukrainian], NTUU KPI, Kiev (2010).

O. E. Kolosov, V. Sivetskii, E. M. Panov, O. Mikulyonok, V. V. Klyavlin, and D. E. Sidorov, Mathematical Modeling of Base Processes in the Production of Polymer Composite Materials with the Use of Ultrasonic Modification [in Ukrainian], VD Edelveys, Kiev (2012).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 7, pp. 42–47, July, 2012.

Rights and permissions

About this article

Cite this article

Kolosov, A.E., Sakharov, A.S., Sivetskii, V.I. et al. Method of selecting efficient design and operating parameters for equipment used for the ultrasonic modification of liquid-polymer composites and fibrous fillers. Chem Petrol Eng 48, 459–466 (2012). https://doi.org/10.1007/s10556-012-9640-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-012-9640-1