Abstract

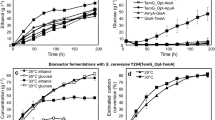

Industrial strains of a polyploid, distiller’s Saccharomyces cerevisiae that produces glucoamylase and α-amylase was used for the direct fermentation of raw starch to ethanol. Strains contained either Aspergillus awamori glucoamylase gene (GA1), Debaryomyces occidentalis glucoamylase gene (GAM1) or D. occidentalis α-amylase gene (AMY), singly or in combination, integrated into their chromosomes. The strain expressing both GA1 and AMY generated 10.3% (v/v) ethanol (80.9 g l−1) from 20% (w/v) raw corn starch after 6 days of fermentation, and decreased the raw starch content to 21% of the initial concentration.

Similar content being viewed by others

References

de Moraes LMP, Astolfi-filho S, Oliver SG (1995) Development of yeast strains for the efficient utilization of starch: evaluation of constructs that express α-amylase and glucoamylase separately or as bifunctional fusion proteins. Appl Microbiol Biotechnol 43:1067–1076

Eksteen JM, van Renseburg P, Cordero Otero RR, Pretorius IS (2003) Starch fermentation by recombinant Saccharomyces cerevisiae strains expressing the α-amylase and glucoamylase genes from Lipomyces kononenkoae and Saccharomycopsis fibuligera. Biotechnol Bioeng 84:639–646

Ghang DM, Yu L, Lim MH, Ko HM, Im SY, Lee HB, Bai S (2007) Efficient one-step starch utilization by industrial strains of Saccharomyces cerevisiae expressing the glucoamylase and α-amylase genes from Debaryomyces occidentalis. Biotechnol Lett 29:1203–1208

Gietz D, St Jean A, Woods R, Schiestl RH (1992) Improved method for high efficiency transformation of intact yeast cells. Nucleic Acids Res 20:1425

Janse BJ, Pretorius IS (1995) One-step enzymatic hydrolysis of starch using a recombinant strain of Saccharomyces cerevisiae producing α-amylase, glucoamylase and pullulanase. Appl Microbiol Biotechnol 42:876–883

Kim JH, Kim HR, Lim MH, Ko HM, Chin JE, Lee HB, Kim IC, Bai S (2010) Construction of a direct starch-fermenting industrial strain of Saccharomyces cerevisiae producing glucoamylase, α-amylase and debranching enzyme. Biotechnol Lett 32:713–719

Lee FWF, Da Silva NA (1997) Improved efficiency and stability of multiple cloned gene insertions at the δ sequences of Saccharomyces cerevisiae. Appl Microbiol Biotechnol 48:339–345

Lin LL, Ma YJ, Chien HR, Hsu WH (1998) Construction of an amylolytic yeast by multiple integration of the Aspergillus awamori glucoamylase gene into a Saccharomyces cerevisiae chromosome. Enzyme Microb Technol 23:360–365

Ma Y, Lin LL, Chien HR, Hsu WH (2000) Efficient utilization of starch by a recombinant strain of Saccharomyces cerevisiae producing glucoamylase and isoamylase. Biotechnol Appl Biochem 31:55–59

Marin D, Jimenez A, Lobato MF (2001) Construction of an efficient amylolytic industrial yeast strain containing DNA exclusively derived from yeast. FEMS Microbiol Lett 201:249–253

Ness F, Lavallee F, Dubourdieu D, Aigle M, Dulau L (1993) Identification of yeast strains using the polymerase chain reaction. J Sci Food Agric 62:89–94

Nieto A, Prieto JA, Sanz P (1999) Stable high-copy number integration of Aspergillus orizae α-amylase cDNA in an industrial baker’s yeast strain. Biotechnol Prog 15:459–466

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Shigechi H, Koh J, Fujita Y, Matsumoto T, Bito Y, Ueda M, Satoh E, Fukuda H, Kondo A (2004) Direct production of ethanol from raw corn starch via fermentation by use of a novel surface-engineered yeast strain codisplaying glucoamylase and α-amylase. Appl Environ Microbiol 70:5037–5040

Sun H, Zhao P, Ge X, Xia Y, Hao Z, Liu J, Peng M (2010) Recent advances in microbial raw starch degrading enzymes. Appl Biochem Biotechnol 160:988–1003

Yamada R, Bito Y, Adachi T, Tanaka T, Ogino C, Fukuda H, Kondo A (2009) Efficient production of ethanol from raw starch by a mated diploid Saccharomyces cerevisiae with integrated α-amylase and glucoamylase genes. Enzyme Microb Technol 44:344–349

Yamada R, Tanaka T, Ogino C, Fukuda H, Kondo A (2010) Novel strategy for yeast construction using δ-integration and cell fusion to efficiently produce ethanol from raw starch. Appl Microbiol Biotechnol 85:1491–1498

Acknowledgments

This work was supported by a grant of the Korea Ministry of Education, Science and Technology (The Regional Core Research Program/Biohousing Research Institute). Ha-Ram Kim and Young-Kum Im were supported by the second stage of the Brain Korea 21 project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, HR., Im, YK., Ko, HM. et al. Raw starch fermentation to ethanol by an industrial distiller’s yeast strain of Saccharomyces cerevisiae expressing glucoamylase and α-amylase genes. Biotechnol Lett 33, 1643–1648 (2011). https://doi.org/10.1007/s10529-011-0613-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-011-0613-9