Abstract

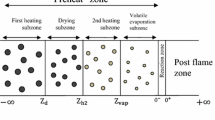

This paper investigates the role of recirculation and non-unity Lewis number on the combustion of organic dust particles. Since recirculation effect is more noticeable in micro-combustors, it is necessary to propose a modeling approach of this phenomenon to better simulate the performance of micro-combustors. In this research, in order to model the combustion of organic dust particles, it is assumed that the dust particles vaporize first to yield a known chemical structure which is oxidized in the gas phase, and the chemical structure of this gaseous fuel is assumed methane. To study the flame structure and solve the governing equations, it is considered that the flame structure consists of three zones titled the preheat-vaporization zone, the narrow reaction zone and finally the post flame zone. The recirculation phenomenon is evaluated by entering the exhausted heat from the post flame zone into the preheat zone. The solution is based on the following approach. First, the governing equations in each zone are nondimensionalized. Then the needed boundary and matching conditions are applied in each zone. After that, these equations and the required boundary and matching conditions are simultaneously solved with the analytical model. Consequently, the remarkable effects of recirculation and non-unity Lewis number on the combustion characteristics of the organic dust particles such as burning velocity and temperature profiles for different particle radii are obtained. The results show reasonable agreement with published experimental data.

Similar content being viewed by others

Abbreviations

- A :

-

parameter characterizing rate of vaporization of fuel particles defined in Eq. (1)

- a :

-

defined in Eq. (22)

- B :

-

frequency factor characterizing rate of gas phase oxidation of the gaseous fuel

- b :

-

scaled mass fraction of fuel at the boundary between the reaction and convection zones

- C :

-

heat capacity of mixture defined in Eq. (9)

- C F :

-

molar concentration of fuel

- C p :

-

heat capacity of the gas

- C s :

-

heat capacity of a fuel particle

- D :

-

dimensionless flame temperature, defined in Eq. (10)

- D u :

-

diffusion coefficient

- E a :

-

activation energy characterizing the gas phase reaction

- H :

-

chamber width

- h :

-

convective heat transfer coefficient between the combustion flow and combustion chamber

- k :

-

heat recirculation coefficient defined in Eq. (15)

- k 1 :

-

defined in Eq. (20)

- k 2 :

-

ratio of convective heat transfer coefficient per the chamber width

- k r :

-

rate constant of the gas-phase reaction

- Le :

-

Lewis number defined in Eq. (15)

- m :

-

defined in Eq. (10)

- n :

-

temperature exponent characterizing rate of vaporization of fuel particles defined in Eq. (1)

- n s :

-

local number density of particles

- n u :

-

number density of particles in ambient reactant stream (number of particles per unit volume)

- Pe :

-

Péclet number defined in Eq. (15)

- Q :

-

heat release per unit mass of gaseous fuel consumed

- Q L :

-

heat exchange between gas and surrounding surface per unit mass

- Q V :

-

heat associated with vaporizing unit mass of fuel

- q :

-

defined in Eq. (15)

- R :

-

gas constant

- r :

-

radius of fuel particle

- T :

-

temperature

- t :

-

defined in Eq. (33)

- v :

-

velocity

- V u :

-

burning velocity calculated neglecting heat of vaporization of fuel particles

- V v :

-

burning velocity calculated including heat of vaporization of fuel particles

- W F :

-

molecular weight of gaseous fuel

- ω :

-

defined in Eq. (15)

- ω F :

-

reaction rate characterizing consumption of gaseous fuel defined in Eq. 31

- ω v :

-

rate of vaporization of fuel particles defined in Eq. (1)

- x :

-

spatial coordinate

- Y :

-

mass fraction

- Y FC :

-

defined in Eq. (11)

- Y Ff :

-

mass fraction of fuel at the reaction zone

- Y Fu :

-

gaseous fuel available in the particles in the ambient reactant stream

- y :

-

defined in Eq. (33)

- y F :

-

defined in Eq. (10)

- y s :

-

defined in Eq. (10)

- Z e :

-

defined in Eq. (2)

- z :

-

scaled independent variable defined in Eq. (10)

- α :

-

defined in Eq. (21)

- γ :

-

defined in Eq. (15)

- ɛ :

-

1/Z e expansion parameter

- η :

-

independent variable defined in Eq. (33)

- θ :

-

scaled independent variable defined in Eq. (10)

- θ 0 :

-

value of θ calculated neglecting heat of vaporization of particles

- Λ:

-

defined in Eq. (39)

- λ :

-

thermal conductivity

- ρ :

-

density of the reactant mixture

- ρ u :

-

density of the unburned mixture

- ρ s :

-

density of a fuel particle

- v :

-

stoichiometric coefficient

- Φu :

-

equivalence ratio based on fuel available in the particles in the ambient reactant stream

- Φs :

-

effective equivalence ratio in the reaction zone.

- b:

-

adiabatic conditions after completion of chemical reactions

- F:

-

gaseous fuel

- f:

-

conditions at the reaction zone

- O2 :

-

oxygen

- s:

-

fuel particles

- u:

-

conditions in the ambient reactant stream

- w:

-

conditions in the wall

References

Cashdollar, K. L. Overview of dust explosibility characteristics. Journal of Loss Prevention in the Process Industries 13(3–5), 183–199 (2000)

Han, O. S., Yashima, M., Matsuda, T., Matsui, H., Miyake, A., and Ogawa, T. Behavior of flame propagating through lycopodium dust clouds in a vertical duct. Journal of Loss Prevention in the Process Industries 13(6), 449–457 (2000)

Han, O. S., Yashima, M., Matsuda, T., Matsui, H., Miyake, A., and Ogawa, T. A study of flame propagation mechanisms in lycopodium dust clouds based on dust particles behaviour. Journal of Loss Prevention in the Process Industries 14(3), 153–160 (2001)

Kurdyumov, V. N. and Fernández-Tarrazo, E. Lewis number effect on the propagation of premixed laminar flames in narrow open ducts. Combustion and Flame 128(4), 382–394 (2002)

Shamim, T. The effect of Lewis number on radiative extinction and flamelet modeling. International Journal of Heat and Mass Transfer 45(6), 1249–1259 (2002)

Proust, C. A few fundamental aspects about ignition and flame propagation in dust clouds. Journal of Loss Prevention in the Process Industries 19(2–3), 104–120 (2006)

Proust, C. Flame propagation and combustion in some dust-air mixtures. Journal of Loss Prevention in the Process Industries 19(1), 89–100 (2006)

Eckhoff, R. K. Differences and similarities of gas and dust explosions: a critical evaluation of the European ‘ATEX’ directives in relation to dusts. Journal of Loss Prevention in the Process Industries 19(6), 553–560 (2006)

Babrauskas, V. Ignition: a century of research and an assessment of our current status. Journal of Fire Protection Engineering 17(3), 165 (2007)

Chakraborty, S., Mukhopadhyay, A., and Sen, S. Interaction of Lewis number and heat loss effects for a laminar premixed flame propagating in a channel. International Journal of Thermal Sciences 47(1), 84–92 (2008)

Chen, Z., Burke, M. P., and Ju, Y. Effects of Lewis number and ignition energy on the determination of laminar flame speed using propagating spherical flames. Proceedings of the Combustion Institute 32(1), 1253–1260 (2009)

Daou, J. and Matalon, M. Influence of conductive heat losses on the propagation of premixed flames in channels. Combustion and Flame 128(4), 321–339 (2002)

Daou, J. and Matalon, M. Flame propagation in channels: differential diffusion effects. 3rd Joint Meeting of the US Sections of the Combustion Institute, Chicago, Illinois (2003).

Ronney, P. D. Analysis of non-adiabatic heat-recirculating combustors. Combustion and Flame 135(4), 421–439 (2003)

Leach, T. T., Cadou, C. P., and Jackson, G. S. Effect of structural heat conduction and heat loss on combustion in micro-channels. Combustion Theory and Modeling 10(1), 85–103 (2006)

Leach, T. T. and Cadou, C. P. The role of structural heat exchange and heat loss in the design of efficient silicon micro-combustors. Proceedings of the Combustion Institute 30(2), 2437–2444 (2005)

Deng, W. W., Klemic, J. F., Li, X. H., Reed, M. A., and Gomez, A. Liquid fuel microcombustor using microfabricated multiplexed electrospray sources. Proceedings of the Combustion Institute 31(2), 2239–2246 (2007)

Bidabadi, M. and Rahbari, A. Modeling combustion of lycopodium particles by considering the temperature difference between the gas and the particles. Combustion, Explosion and Shock Waves 45(3), 49–57 (2009)

Bidabadi, M., Haghiri, A., and Rahbari, A. The effect of Lewis and Damköhler numbers on the flame propagation through micro organic dust particles. International Journal of Thermal Sciences 49(3), 534–542 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Zhe-wei ZHOU

Rights and permissions

About this article

Cite this article

Bidabadi, M., Fanaee, A. & Rahbari, A. Investigation over the recirculation influence on the combustion of micro organic dust particles. Appl. Math. Mech.-Engl. Ed. 31, 685–696 (2010). https://doi.org/10.1007/s10483-010-1303-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-010-1303-7