Abstract

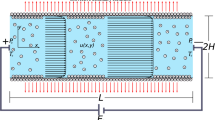

This paper presents a numerical analysis of Joule heating effect of electroosmosis in a finite-length microchannel made of the glass and polydimethylsiloxane (PDMS) polymer. The Poisson-Boltzmann equation of electric double layer, the Navier-Stokes equation of liquid flow, and the liquid-solid coupled heat transfer equation are solved to investigate temperature behaviors of electroosmosis in a two-dimensional microchannel. The feedback effect of temperature variation on liquid properties (dielectric constant, viscosity, and thermal and electric conductivities) is taken into account. Numerical results indicate that there exists a heat developing length near the channel inlet where the flow velocity, temperature, pressure, and electric field rapidly vary and then approach to a steady state after the heat developing length, which may occupy a considerable portion of the microchannel in cases of thick chip and high electric field. The liquid temperature of steady state increases with the increase of the applied electric field, channel width, and chip thickness. The temperature on a PDMS wall is higher than that on a glass wall due to the difference of heat conductivities of materials. Temperature variations are found in the both longitudinal and transverse directions of the microchannel. The increase of the temperature on the wall decreases the charge density of the electric double layer. The longitudinal temperature variation induces a pressure gradient and changes the behavior of the electric field in the microchannel. The inflow liquid temperature does not change the liquid temperature of steady state and the heat developing length.

Similar content being viewed by others

References

Bayraktar, Tuba and Pidugu, Srikanth B. Characterization of liquid flows in microfluidic systems. Int. J. Heat Mass Transfer 49(5–6), 815–824 (2006)

Stone, H. A., Stroock, A. D., and Ajdari, A. Engineering flows in small devices: microfluidics toward a lab-on-a-chip. Annual Review of Fluid Mechanics 36, 381–411 (2004)

Probstein, R. F. Physicochemical Hydrodynamics: An Introduction, John Wiley and Sons, Inc., New York (1994)

Jones, A. E. and Grushka, E. Nature of temperature gradients in capillary zone electrophoresis. J. Chromatogr. A 466, 219–225 (1989)

Knox, J. H. Thermal effects and band spreading in capillary electro-separation. Chromatographia 26, 329–337 (1988)

Grushka, E., McCormick, R. M., and Kirkland, J. J. Effect of temperature gradients on the efficiency of capillary zone electrophoresis separations. Anal. Chem. 61, 241–246 (1989)

Knox, J. H. and McCormack, K. A. Temperature effects in capillary electrophoresis, 1: internal capillary temperature and effect upon performance. Chromatographia 38, 207–214 (1994)

Knox, J. H. and McCormack, K. A. Temperature effects in capillary electrophoresis, 2: theoretical calculations and predictions. Chromatographia 38, 215–221 (1994)

Zade, Azad Qazi, Manzari, Mehrdad T., and Hannani, Siamak K. An analytical solution for thermally fully developed combined pressure-electroosmotically driven flow in microchannels. Int. J. Heat Mass Transfer 50, 1087–1096 (2007)

Horiuchi, Keisuke and Dutta, Prashanta. Joule heating effects in electroosmotically driven microchannel flows. Int. J. Heat Mass Transfer 47, 3085–3095 (2004)

Dutta, P. and Horiuchi, Keisuke. Thermal characteristics of mixed electroosmotic and pressuredriven microflows. Comput. Math. Appl. 53, 651–670 (2006)

Tang, G. Y., Yang, C., Chai, C. K., and Gong, H. Q. Numerical analysis of the thermal effect on electroosmotic flow and electrokinetic mass transport in microchannels. Anal. Chim. Acta 507, 27–37 (2004)

Tang, G. Y., Yang, C., Chai, J. C., and Gong, H. Q. Joule heating effect on electroosmotic flow and mass species transport in a microcapillary. Int. J. Heat Mass Transfer 47, 215–227 (2004)

Tang, Gongyue, Yan, Deguang, Yang, Chun, Gong, Haiqing, Chai, Cheekiong, and Lam, Yeecheong. Joule heating and its effects on electrokinetic transport of solutes in rectangular microchannels. Sens. Actuators A 139, 221–232 (2007)

Xuan, Xiangchun, Sinton, David, and Li, Dongqing. Thermal end effects on electroosmotic flow in a capillary. Int. J. Heat Mass Transfer 47, 3145–3157 (2004)

Eteshola, E. and Leckband, D. Development and characterization of an ELISA assay in PDMS microfluidic channels. Sens. Actuators B 72, 129–133 (2001)

Brugger, J., Beljakovic, G., Despont, M., Biebuyck, H., De Rooij, N. F., and Vettiger, P. Low-cost PDMS seal ring for single-side wet etching of MEMS structures. Sens. Actuators A 70, 191–194 (1998)

Fu, R., Xu, B., and Li, D. Study of the temperature field in microchannels of a PDMS chip with embedded local heater using temperature-dependent fluorescent dye. Int. J. Therm. Sci. 45, 841–847 (2006)

Jeong, Ok Chan and Konishi, Satoshi. Fabrication and drive test of pneumatic PDMS micro pump. Sens. Actuators A 135, 849–856 (2007)

Weast, R., Astle, M. J., and Beyer, W. H. CRC Handbook of Chemistry and Physics, CRC Press, Inc., Boca Raton (1986)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Jian-zhong LIN

Project supported by the National Natural Science Foundation of China (Nos.10872076 and 50805059)

Rights and permissions

About this article

Cite this article

Chao, K., Wu, Jk. & Chen, B. Joule heating effect of electroosmosis in a finite-length microchannel made of different materials. Appl. Math. Mech.-Engl. Ed. 31, 109–118 (2010). https://doi.org/10.1007/s10483-010-0111-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-010-0111-z