Abstract

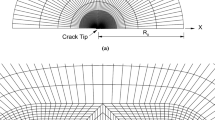

Void closing from a spherical shape to a crack is investigated quantitatively in the present study. The constitutive relation of the void-free matrix is assumed to obey the Norton power law. A representative volume element (RVE) which includes matrix and void is employed and a Rayleigh-Ritz procedure is developed to study the deformation-rates of a spherical void and a penny-shaped crack. Based on an approximate interpolation scheme, an analytical model for void closure in nonlinear plastic materials is established. It is found that the local plastic flows of the matrix material are the main mechanism of void deformation. It is also shown that the relative void volume during the deformation depends on the Norton exponent, on the far-field stress triaxiality, as well as on the far-field effective strain. The predictions of void closure using the present model are compared with the corresponding results in the literature, showing good agreement. The model for void closure provides a novel way for process design and optimization in terms of elimination of voids in billets because the model for void closure can easily be applied in the CAE analysis.

Similar content being viewed by others

Abbreviations

- A,A (i) k :

-

coefficients in stream function

- Ė :

-

macroscopic strain-rate tensor

- Ė 0, v 0 :

-

strain-rate and velocity in the absence of the void

- n :

-

Norton exponent

- n :

-

unit normal vector

- r, θ, φ :

-

spherical coordinates

- sign:

-

signum function

- S R, S :

-

surface of the RVE, surface of the void

- v,\( \tilde \upsilon \) :

-

local velocity, additional velocity

- V R, V M :

-

volume of the RVE, volume of the matrix material in the RVE

- V, V 0 :

-

current void volume, initial void volume

- σ,σ′, σ e :

-

local stress tensor, stress deviator and effective stress

- σ 0, \( \dot \varepsilon \) 0 :

-

reference stress, reference strain-rate

- \( \dot \varepsilon ,\dot \tilde \varepsilon ,\dot \varepsilon _e \) :

-

local strain-rate tensor, additional strain-rate tensor and effective strain-rate

- Σ,Σ′ :

-

macroscopic stress tensor and stress deviator

- Σm,Σe :

-

macroscopic mean stress and effective stress

- ζ :

-

stream function

References

Dudra, S. P. and Im, Y. T. Analysis of void closure in open-die forging. Int. J. Mach. Tools Manufact. 30(1), 65–75 (1990)

Wallerö, A. Closing of a central longitudinal pore in hot rolling. J. Mech. Work Technol. 12(2), 233–242 (1985)

Keife, H. and Ståhlberg, U. Influence of pressure on the closure of voids during plastic deformation. J. Mech. Work. Technol. 4, 133–143 (1980)

Ståhlberg, U., Keife, H., Lundberg, M., and Melander, A. A study of void closure during plastic deformation. J. Mech. Work. Technol. 4, 51–63 (1980)

Ståhlberg, U. Influence of spread and stress on the closure of a central longitudinal hole in the hot rolling of steel. J. Mech. Work. Technol. 13(1), 65–81 (1986)

Tanaka, M., Ono, S., and Tsuneno, M. Factors contributing to crushing of voids during forging. J. Jpn. Soci. Technol. Plast. 27(306), 852–859 (1986)

Tanaka, M., Ono, S., and Tsuneno, M. A numerical analysis on void crushing during side compression of round bar by flat dies. J. Jpn. Soci. Technol. Plast. 28, 238–244 (1987)

Tanaka, M., Ono, S., Tsuneno, M., and Ivadate, T. An analysis of void crushing during flat die free forging. Proceedings of the 2nd International Conference on Technology of Plasticity (ICTP), Vol. 2, Stuttgart, Germany, 1035–1042 (1987)

Park, C. Y. and Yang, D. Y. Modelling of void crushing for large-ingot hot forging. J. Mater. Process. Technol. 67, 195–200 (1997)

Pietrzyk, M., Kawalla, R., and Pircher, H. Simulation of the behavior of voids in steel plates during hot rolling. Steel Res. 66(12), 526–529 (1995)

Cui, Zhenshan, Ren, Guangsheng, Xu, Bingye, Xu, Chunguo, and Liu, Guihua. Void closing conditions for solid cylinders during hot forging (in Chinese). J. Tsinghua Univ. 43(2), 227–229, 233 (2003)

Wang, A., Thomson, P. F., and Hodgson, P. D. A study of pore closure and welding in hot rolling process. J. Mater. Process. Technol. 60, 95–102 (1996)

Chaaban, M. A. and Alexander, J. M. A study of the closure of cavities in swing forging. Proceedings of the 17th International Machine and Tool Design Research Conference (ed. Tobias, S. A.), Birmingham, UK, 633–645 (1976)

Nakasaki, M., Takasu, I., and Utsunomiya, H. Application of hydrostatic integration parameter for free-forging and rolling. J. Mater. Process. Technol. 177, 521–524 (2006)

McClintock, F. A. A criterion for ductile fracture by growth of holes. J. Appl. Mech. 35, 363–371 (1968)

Rice, J. R. and Tracey, D. M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 17, 201–217 (1969)

Gurson, A. L. Continuum theory of ductile rupture by void nucleation and growth: Part I—Yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99, 2–15 (1977)

Søik, O. P. and Thaulow, C. Growth of spheroidal voids in elastic-plastic solids. Fatigue Fract. Engng. Mater. Struct. 20(12), 1731–1744 (1997)

Budiansky, B., Hutchinson, J. W., and Slutsky, S. Void growth and collapse in viscous solids. Mechanics of Solids (eds. Hopkins, H. G. and Sewell, M. J.), Pergamon Press, Oxford, 13–45 (1982)

Duva, J. M. A constitutive description of nonlinear materials containing voids. Mech. Mater. 5, 137–144 (1986)

Cocks, A. Inelastic deformation of porous materials. J. Mech. Phys. Solids 37, 693–715 (1989)

Wang, T. C. and Qin, J. L. Constitutive potential for void-containing nonlinear material and void growth (in Chinese). Acta Mechanica Solida Sinica 2, 127–142 (1989)

Leblond, J. B., Perrin, G., and Suquet, P. Exact results and approximate models for porous viscoplastic solids. International Journal of Plasticity 10(3), 213–235 (1994)

Liu, Y. and Huang, Z. P. Macroscopic strain potentials in nonlinear porous materials. Acta Mechanica Sinica 19(1), 52–58 (2003)

Huang, Z. P. and Wang, J. Nonlinear mechanics of solids containing isolated voids. ASME Appl. Mech. Rev. 59, 210–229 (2006)

Hsu, C. Y., Lee, B. J., and Mear, M. E. Constitutive models for power-law viscous solids containing spherical voids. Int. J. Plasticity 25(1), 134–160 (2009)

Flandi, L. and Leblond, J. B. A new model for porous nonlinear viscous solids incorporating void shape effects—I: Theory. Eur. J. Mech. A/Solids 24, 537–551 (2005)

Gologanu, M., Leblond, J. B., and Devaux, J. Approximate models for ductile metals containing nonspherical voids—case of axisymmetric prolate ellipsoidal cavities. J. Mech. Phys. Solids 41, 1723–1754 (1993)

Gologanu, M., Leblond, J. B., and Devaux, J. Approximate models for ductile metals containing nonspherical voids—case of axisymmetric oblate ellipsoidal cavities. J. Eng. Mater. Technol. 116, 290–297 (1994)

Li, Zhenhuan and Huang, Minsheng. Combined effects of void shape and void size-oblate spheroidal microvoid embedded in infinite non-linear solid. Int. J. Plasticity 21, 625–650 (2005)

Pardoen, T. and Hutchinson, J. W. An extended model for void growth and coalescence. J. Mech. Phys. Solids 48, 2467–2512 (2000)

Lee, B. J. and Mear, M. E. Axisymmetric deformations of power-law solids containing a dilute concentration of aligned spheroidal voids. J. Mech. Phys. Solids 40, 1805–1836 (1992)

Lee, B. J. and Mear, M. E. Studies of the growth and collapse of voids in viscous solids. J. Eng. Mater. Technol. 116, 348–358 (1994)

Yee, K. C. and Mear, M. E. Effect of void shape on the macroscopic response of non-linear porous solids. Int. J. Plasticity 12, 45–68 (1996)

Norton, F. H. Creep of Steel at High Temperature, McGraw-Hill, New York (1929)

Duva, J. M. and Hutchinson, J. W. Constitutive potentials for dilutely voided nonlinear materials. Mech. Mater. 3(1), 41–54 (1984)

Wilkinson, D. S. and Ashby, M. F. Pressure sintering by power law creep. Acta Metall. 23, 1277–1285 (1975)

Tvergaard, V. On the creep constrained diffusive cavitation of grain boundary facets. J. Mech. Phys. Solids 32(5), 373–393 (1984)

He, M. Y. and Hutchinson, J. W. The penny-shaped crack and the plane strain crack in an infinite body of power-law material. J. Appl. Mech. 48, 830–840 (1981)

Hutchinson, J. W. Constitutive behavior and crack tip fields for materials undergoing creep-constrained grain boundary cavitation. Acta Metall. 31(7), 1079–1088 (1983)

Banks-sills, L. and Budiansky, B. On void collapse in viscous solids. Mechanics of Materials 1, 209–218 (1982)

Author information

Authors and Affiliations

Corresponding author

Additional information

(Communicated by Zhu-ping HUANG)

Project supported by the National Basic Research Program of China (973 Program) (No. 2006CB705401)

Rights and permissions

About this article

Cite this article

Zhang, Xx., Cui, Zs. Theoretical study of void closure in nonlinear plastic materials. Appl. Math. Mech.-Engl. Ed. 30, 631–642 (2009). https://doi.org/10.1007/s10483-009-0509-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-009-0509-7