Abstract

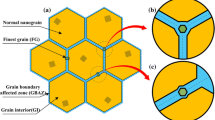

The rule-of-mixture approach has become one of the widely spread ways to investigate the mechanical properties of nano-materials and nano-structures, and it is very important for the simulation results to exactly compute phase volume fractions. The nanocrystalline (NC) materials are treated as three-phase composites consisting of grain core phase, grain boundary (GB) phase and triple junction phase, and a two-dimensional three-phase mixture regular polygon model is established to investigate the scale effect of mechanical properties of NC materials due to the geometrical polyhedron characteristics of crystal grain. For different multi-sided geometrical shapes of grains, the corresponding regular polygon model is adopted to obtain more precise phase volume fractions and exactly predict the mechanical properties of NC materials.

Similar content being viewed by others

References

Hall E O. The deformation and aging of mild steel: III discussion of results[J]. Proc Phys Soc B, 1951, 64(1):747–753.

Petch N J. The cleavage strength of polycrystals[J]. J Iron Steel Inst, 1953, 174(5):25–28.

Gleiter H. Nanocrystalline materials[J]. Prog Mater Sci, 1989, 33(4):223–315.

Nieman G W, Weertman J R, Siegel R W. Microhardness of nanocrystalline palladium and copper produced by inert-gas condensation[J]. Scripta Metall, 1989, 23(13):2013–2018.

Palumbo G, Erb U, Aust K T. Triple line disclination effects on the mechanical behaviour of materials[J]. Scripta Metall Mater, 1990, 24(12):2347–2350.

Lu K. Nanocrystalline metals crystallized from amorphous solids: nanocrystallization, structure, and properties[J]. Mater Sci Eng R, 1996, 16:161–221.

Mallow T R, Koch C C. Grain growth in nanocrystalline iron prepared by mechanical attrition[J]. Acta Mater, 1997, 45(5):2177–2186.

Sanders P G, Eastman J A, Weertman J R. Elastic and tensile behavior of nanocrystalline copper and palladium[J]. Acta Mater, 1997, 45(17):4019–4025.

Masumura R A, Hazzledine P M, Pande C S. Yield stress of fine grained materials[J]. Acta Mater, 1998, 46(13):4527–4534.

Yamakov V, Wolf D, Phillpot S R, Gleiter H. Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation[J]. Acta Mater, 2002, 50(1):61–73.

Seattergood R O, Koch C C. A modified model for hall-petch behavior in nanocrystalline materials[J]. Scripta Mater, 1992, 27(9):1195–1200.

Hahn H, Padmanabhan K A. A model for the deformation of nanocrystalline materials[J]. Phil Mag B, 1997, 76(44):559–571.

Fedorov A A, Gutkin M Yu, Ovid’ko I A. Transformations of grain boundary dislocation pile-ups in nano- and polycrystalline materials[J]. Acta Mater, 2003, 51(4):887–898.

Fedorov A A, Gutkin M Yu, Ovid’ko I A. Triple junction diffusion and plastic flow in fine-grained materials[J]. Scripta Mater, 2002, 47(1):51–55.

Gutkin M Yu, Kolesnikova A L, Ovid’ko I A, Skiba N V. Disclinations and rotational deformation in fine-grained materials[J]. Phil Mag Lett, 2002, 82(12):651–657.

Ovid’ko I A. Materials science: deformation of nanostructures[J]. Science, 2002, 295(2395):2386–2386.

Gutkin M Yu, Ovid’koy I A. Yield stress of nanocrystalline materials: role of grain boundary dislocations, triple junctions and Coble creep[J]. Philosophical Magazine, 2004, 84(9):847–863.

Kocks U F. Relation between polycrystal deformation and single-crystal deformation[J]. Metal Trans, 1970, 1(55):1121–1143.

Carsley J E, Ning J, Milligan W W, Hackney S A, Aifantis E C. A simple, mixtures-based model for the grain size dependence of strength in nanophase metals[J]. Nanostruct Mater, 1995, 5(4):441–448.

Konstantinidis D A, Aifantis E C. On the “anomalous” hardness of nanocrystalline materials[J]. Nanostruct Mater, 1998, 10(7):1111–1118.

Benson David J, Fu Hsueh-hung, Meyers Marc André. On the effect of grain size on yield stress: extension into nanocrystalline domain[J]. Mat Sci Eng A, 2001, 319–321:854–861.

Song H W, Guo S R, Hu Z Q. A coherent polycrystal model for the inverse Hall-Petch relation in nanocrystalline materials[J]. Nanostruct Mater, 1999, 11(2):203–210.

Xiang Qing, Guo Xingming. The scale effect on the yield strength of nanocrystalline materials[J]. Internat J Solids Struct, 2006, 43(9):7793–7799.

Wang N, Wang Z, Aust K T, Erb U. Effect of grain size on mechanical properties of nanocrystalline materials[J]. Acta Metal Mater, 1995, 43(2):519–528.

Kim H S. A composite model for mechanical properties of nanocrystalline materials[J]. Scripta Mater, 1998, 39(8):1057–1061.

Kim H S, Bush M B. The effects of grain size and porosity on the elastic modulus of nanocrystalline materials[J]. Nanostruct Mater, 1999, 11(3):361–367.

Kim H S, Estrin Y, Bush M B. Plastic deformation behaviour of fine-grained materials[J]. Acta Mater, 2000, 48(2):493–504.

Kim H S, Estrin Y. Phase mixture modeling of the strain rate dependent mechanical behavior of nanostructured materials[J]. Acta Mater, 2005, 53(3):765–772.

Gutkin M Yu, Ovid’ko I A, Pande C S. Theoretical models of plastic deformation process in nanocrystalline materials[J]. Rev Adv Mater Sci, 2001, 2(1):80–102.

Tjong S C, Chen Haydn. Nanocrystalline materials and coating[J]. Mat Sci Eng R, 2004, 45(1):1–88.

Zhou Y, Erb U, Aust K T, Palumbo G. The effects of triple junctions and grain boundaries on hardness and Young’s modulus in nanostructured Ni-P[J]. Scripta Mater, 2003, 48(6):825–830.

Zhao M, Li J C, Jiang Q. Hall-Petch relationship in nanometer size range[J]. J Alloy Compd, 2003, 361(2):160–164.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributed by GUO Xing-ming

Project supported by the National Natural Science Foundation of China (No.10472061), Key Project of Shanghai Municipal Commission of Science and Technology (No.04JC14034), the Doctoral Foundation of Ministry of Education of China (No.20060280015) and Shanghai Leading Academic Discipline Project (No.Y0103)

Rights and permissions

About this article

Cite this article

Guo, H., Guo, Xm. Scale effect and geometric shapes of grains. Appl Math Mech 28, 141–149 (2007). https://doi.org/10.1007/s10483-007-0201-1

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s10483-007-0201-1

Key words

- nanocrystalline (NC) material

- phase mixture regular polygon models

- yield stress

- volume fractions

- grain boundary (GB)