Abstract

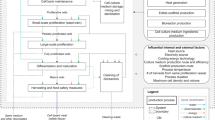

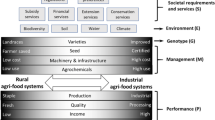

The global food insecurity, malnourishment and rising world hunger are the major hindrances in accomplishing the zero hunger sustainable development goal by 2030. Due to the continuous increment of wheat production in the past few decades, India received the second rank in the global wheat production after China. However, storage capacity has not been expanded with similar extent. The administrative bodies in India are constructing several capacitated silos in major geographically widespread producing and consuming states to curtail this gap. This paper presents a multi-period single objective mathematical model to support their decision-making process. The model minimizes the silo establishment, transportation, food grain loss, inventory holding, carbon emission, and risk penalty costs. The proposed model is solved using the variant of the particle swarm optimization combined with global, local and near neighbor social structures along with traditional PSO. The solutions obtained through two metaheuristic algorithms are compared with the optimal solutions. The impact of supply, demand and capacity of silos on the model solution is investigated through sensitivity analysis. Finally, some actionable theoretical and managerial implications are discussed after analysing the obtained results.

Similar content being viewed by others

References

Akkerman, R., Farahani, P., & Grunow, M. (2010). Quality, safety and sustainability in food distribution: A review of quantitative operations management approaches and challenges. OR Spectrum, 32(4), 863–904.

Alagusundaram, K. (2016). Should India consider shifting to bulk food grain storage system?—A conceptual frame work. In Proceedings of the 10th International Conference on Controlled Atmosphere and Fumigation in Stored Products (CAF2016), CAF Permanent Committee Secretariat, Winnipeg, Canada (pp. 431–437).

Aliano Filho, A., de Oliveira Florentino, H., Pato, M. V., Poltroniere, S. C., & da Silva Costa, J. F. (2019). Exact and heuristic methods to solve a bi-objective problem of sustainable cultivation. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03468-9.

Allaoui, H., Guo, Y., Choudhary, A., & Bloemhof, J. (2018). Sustainable agro-food supply chain design using two-stage hybrid multi-objective decision-making approach. Computers & Operations Research, 89, 369–384.

An, K., & Ouyang, Y. (2016). Robust grain supply chain design considering post-harvest loss and harvest timing equilibrium. Transportation Research Part E: Logistics and Transportation Review, 88, 110–128.

Arabani, A. B., & Farahani, R. Z. (2012). Facility location dynamics: An overview of classifications and applications. Computers & Industrial Engineering, 62(1), 408–420.

Ardjmand, E., Young, W. A., Weckman, G. R., Bajgiran, O. S., Aminipour, B., & Park, N. (2016). Applying genetic algorithm to a new bi-objective stochastic model for transportation, location, and allocation of hazardous materials. Expert Systems with Applications, 51, 49–58.

Asgari, N., Farahani, R. Z., Rashidi-Bajgan, H., & Sajadieh, M. S. (2013). Developing model-based software to optimise wheat storage and transportation: A real-world application. Applied Soft Computing Journal, 13(2), 1074–1084.

Banasik, A., Kanellopoulos, A., Claassen, G. D. H., Bloemhof-Ruwaard, J. M., & van der Vorst, J. G. (2017). Assessing alternative production options for eco-efficient food supply chains using multi-objective optimization. Annals of Operations Research, 250(2), 341–362.

Bilgen, B., & Ozkarahan, I. (2007). A mixed-integer linear programming model for bulk grain blending and shipping. International Journal of Production Economics, 107(2), 555–571.

Boonmee, A., & Sethanan, K. (2016). A GLNPSO for multi-level capacitated lot-sizing and scheduling problem in the poultry industry. European Journal of Operational Research, 250(2), 652–665.

Chan, F. T., Wang, Z. X., Goswami, A., Singhania, A., & Tiwari, M. K. (2020). Multi-objective particle swarm optimisation based integrated production inventory routing planning for efficient perishable food logistics operations. International Journal of Production Research. https://doi.org/10.1080/00207543.2019.1701209.

Chauhan, A., Kaur, H., Yadav, S., & Jakhar, S. K. (2019). A hybrid model for investigating and selecting a sustainable supply chain for agri-produce in India. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03190-6.

De, A., Mogale, D. G., Zhang, M., Pratap, S., Kumar, S. K., & Huang, G. Q. (2019). Multi-period multi-echelon inventory transportation problem considering stakeholders behavioural tendencies. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2019.107566.

Department of Food & Public Distribution, Ministry of Consumer affairs, Food & Public Distribution. PDS Portal of India. Retrieved February 17, 2017, from http://www.pdsportal.nic.in/main.aspx/.

Department of Food & Public Distribution, Ministry of Consumer Affairs, Food & Public Distribution. Public Distribution, NFSA & Computerisation. Retrieved February 5, 2017, from http://dfpd.nic.in/nfsa-act.htm.

Diabat, A., Govindan, K., & Panicker, V. V. (2012). Supply chain risk management and its mitigation in a food industry. International Journal of Production Research, 50(11), 3039–3050.

Dora, M., Wesana, J., Gellynck, X., Seth, N., Dey, B., & De Steur, H. (2019). Importance of sustainable operations in food loss: Evidence from the Belgian food processing industry. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03134-0.

Eberhart, R., & Kennedy, J. (1995.). A new optimizer using particle swarm theory.In MHS’95. Proceedings of the sixth international symposium on micro machine and human science (pp. 39–43).

Eskandarpour, M., Dejax, P., Miemczyk, J., & Péton, O. (2015). Sustainable supply chain network design: An optimization-oriented review. Omega, 54, 11–32.

Eskandarpour, M., Dejax, P., & Péton, O. (2017). A large neighborhood search heuristic for supply chain network design. Computers & Operations Research, 80, 23–37.

Esteso, A., Alemany, M. M., & Ortiz, A. (2018). Conceptual framework for designing agri-food supply chains under uncertainty by mathematical programming models. International Journal of Production Research, 56(13), 4418–4446.

Etemadnia, H., Goetz, S. J., Canning, P., & Tavallali, M. S. (2015). Optimal wholesale facilities location within the fruit and vegetables supply chain with bimodal transportation options: An LP-MIP heuristic approach. European Journal of Operational Research, 244(2), 648–661.

FAO. (2011). Global food losses and food waste—Extent, causes and prevention. Rome.

FAO, Ifad, UNICEF, WFP, & WHO. (2019). The state of food security and nutrition in the world 2019. Safeguarding against economic slowdowns and downturns. Rome: FAO.

Farahani, R. Z., SteadieSeifi, M., & Asgari, N. (2010). Multiple criteria facility location problems: A survey. Applied Mathematical Modelling, 34(7), 1689–1709.

Florentino, H. D. O., Cantane, D. R., Jones, D. F., Ouelhadj, D., Khosravi, B., & Irawan, C. A. (2020). An optimization model for combined selecting, planting and harvesting sugarcane varieties. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03610-y.

Food Corporation of India. Retrieved January 5, 2018, from http://fci.gov.in/movements.php?view=32.

Ge, H., Goetz, S., Canning, P., & Perez, A. (2018). Optimal locations of fresh produce aggregation facilities in the United States with scale economies. International Journal of Production Economics, 197(January), 143–157.

Ge, H., Gray, R., & Nolan, J. (2015). Agricultural supply chain optimization and complexity: A comparison of analytic vs simulated solutions and policies. International Journal of Production Economics, 159, 208–220.

Gholamian, M. R., & Taghanzadeh, A. H. (2017). Integrated network design of wheat supply chain: A real case of Iran. Computers and Electronics in Agriculture, 140, 139–147.

Göbel, C., Langen, N., Blumenthal, A., Teitscheid, P., & Ritter, G. (2015). Cutting food waste through cooperation along the food supply chain. Sustainability, 7(2), 1429–1445.

Govindan, K., Jafarian, A., Khodaverdi, R., & Devika, K. (2014). Two-echelon multiple-vehicle location-routing problem with time windows for optimization of sustainable supply chain network of perishable food. International Journal of Production Economics, 152, 9–28.

Gustavsson, J., Cederberg, C., Sonesson, U., Van Otterdijk, R., & Meybeck, A. (2011). Global food losses and food waste: Extent, causes and prevention, FAO, Rome, Italy. Retrieved August 12, 2018 from http://www.fao.org/docrep/014/mb060e/mb060e00.pdf.

Hamadani, A. Z., Abouei Ardakan, M., Rezvan, T., & Honarmandian, M. M. (2013). Location-allocation problem for intra-transportation system in a big company by using meta-heuristic algorithm. Socio-Economic Planning Sciences, 47(4), 309–317.

Hosseini-Motlagh, S. M., Samani, M. R. G., & Saadi, F. A. (2019). A novel hybrid approach for synchronized development of sustainability and resiliency in the wheat network. Computers and Electronics in Agriculture, 168, 105095.

Kaur, H. (2019). Modelling internet of things driven sustainable food security system. Benchmarking: An International Journal. https://doi.org/10.1108/BIJ-12-2018-0431.

Ketzenberg, M., Bloemhof, J., & Gaukler, G. (2015). Managing perishables with time and temperature history. Production and Operations Management, 24(1), 54–70.

Khalifehzadeh, S., Seifbarghy, M., & Naderi, B. (2015). A four-echelon supply chain network design with shortage: Mathematical modeling and solution methods. Journal of Manufacturing Systems, 35, 164–175.

Khamjan, W., Khamjan, S., & Pathumnakul, S. (2013). Determination of the locations and capacities of sugar cane loading stations in Thailand. Computers & Industrial Engineering, 66(4), 663–674.

Kiil, K., Dreyer, H. C., Hvolby, H. H., & Chabada, L. (2018). Sustainable food supply chains: The impact of automatic replenishment in grocery stores. Production Planning & Control, 29(2), 106–116.

Krishnan, R., Agarwal, R., Bajada, C., & Arshinder, K. (2020). Redesigning a food supply chain for environmental sustainability—An analysis of resource use and recovery. Journal of Cleaner Production, 242, 118374.

Leat, P., & Revoredo-Giha, C. (2013). Risk and resilience in agri-food supply chains: The case of the ASDA PorkLink supply chain in Scotland. Supply Chain Management: An International Journal, 18(2), 219–231.

Liotta, G., Stecca, G., & Kaihara, T. (2015). Optimisation of freight flows and sourcing in sustainable production and transportation networks. International Journal of Production Economics, 164, 351–365.

Maiyar, L. M., & Thakkar, J. J. (2017). A combined tactical and operational deterministic food grain transportation model: Particle swarm based optimization approach. Computers & Industrial Engineering, 110, 30–42.

Maiyar, L. M., & Thakkar, J. J. (2019). Modelling and analysis of intermodal food grain transportation under hub disruption towards sustainability. International Journal of Production Economics. https://doi.org/10.1016/J.IJPE.2018.07.021.

Melo, M. T., Nickel, S., & Saldanha-da-Gama, F. (2009). Facility location and supply chain management—A review. European Journal of Operational Research, 196, 401–412.

Milman, O. (2015). Earth has lost a third of arable land in past 40 years, scientists say. Retrieved August 14, 2019, from https://www.theguardian.com/environment/2015/dec/02/arable-land-soil-food-security-shortage.

Mishra, N., & Singh, A. (2018). Use of twitter data for waste minimisation in beef supply chain. Annals of Operations Research, 270(1–2), 337–359.

Mogale, D. G., Cheikhrouhou, N., & Tiwari, M. K. (2019a). Modelling of sustainable food grain supply chain distribution system: A bi-objective approach. International Journal of Production Research. https://doi.org/10.1080/00207543.2019.1669840.

Mogale, D. G., Ghadge, A., Kumar, S. K., & Tiwari, M. K. (2019b). Modelling supply chain network for procurement of food grains in India. International Journal of Production Research. https://doi.org/10.1080/00207543.2019.1682707.

Mogale, D. G., Kumar, M., Kumar, S. K., & Tiwari, M. K. (2018a). Grain silo location-allocation problem with dwell time for optimization of food grain supply chain network. Transportation Research Part E: Logistics and Transportation Review, 111, 40–69.

Mogale, D. G., Kumar, S. K., Márquez, F. P. G., & Tiwari, M. K. (2017). Bulk wheat transportation and storage problem of public distribution system. Computers & Industrial Engineering, 104, 80–97.

Mogale, D. G., Kumar, S. K., & Tiwari, M. K. (2018b). An MINLP model to support the movement and storage decisions of the Indian food grain supply chain. Control Engineering Practice, 70, 98–113.

Mohammed, Ahmed, & Wang, Qian. (2017). The Fuzzy Multi-Objective Distribution Planner for a Green Meat Supply Chain. International Journal of Production Economics, 184, 47–58.

Naderi, B., Govindan, K., & Soleimani, H. (2019). A Benders decomposition approach for a real case supply chain network design with capacity acquisition and transporter planning: Wheat distribution network. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03137-x.

Nicholson, C. F., Gómez, M. I., & Gao, O. H. (2011). The costs of increased localization for a multiple-product food supply chain: Dairy in the United States. Food Policy, 36(2), 300–310.

Nourbakhsh, S. M., Bai, Y., Maia, G. D. N., Ouyang, Y., & Rodriguez, L. (2016). Grain supply chain network design and logistics planning for reducing post-harvest loss. Biosystems Engineering, 151, 105–115.

Orgut, I. S., Ivy, J., & Uzsoy, R. (2017). Modeling for the equitable and effective distribution of food donations under stochastic receiving capacities. IISE Transactions, 49(6), 567–578.

Orjuela-Castro, J. A., Sanabria-Coronado, L. A., & Peralta-Lozano, A. M. (2017). Coupling facility location models in the supply chain of perishable fruits. Research in Transportation Business and Management, 24, 73–80.

Paksoy, T., Pehlivan, N. Y., & Özceylan, E. (2012). Application of fuzzy optimization to a supply chain network design: A case study of an edible vegetable oils manufacturer. Applied Mathematical Modelling, 36(6), 2762–2776.

Parwez, S. (2014). Food supply chain management in Indian Agriculture: Issues, opportunities and further research. African Journal of Business Management, 8(14), 572–581.

Pongchairerks, P., & Kachitvichyanukul, V. (2009). Particle swarm optimization algorithm with multiple social learning structures. International Journal of Operational Research, 6(2), 176–194.

Ramanathan, V., S. Sundar, R. Harnish, S. Sharma, J. Seddon, B. Croes, A. Lloyd, et al. (2014). India California air pollution mitigation program: Options to reduce road transport pollution in India. Published by The Energy and Resources Institute in collaboration with the University of California at San Diego and the California Air Resources Board.

Rancourt, M. È., Cordeau, J. F., Laporte, G., & Watkins, B. (2015). Tactical network planning for food aid distribution in Kenya. Computers & Operations Research, 56, 68–83.

Raut, R. D., Gardas, B. B., Kharat, M., & Narkhede, B. (2018). Modeling the drivers of post-harvest losses–MCDM approach. Computers and Electronics in Agriculture, 154, 426–433.

Report of the Comptroller and Auditor General of India. (2013). Storage management and movement of food grains in food corporation of India. New Delhi: Union Government Ministry of Consumer Affairs, Food and Public Distribution.

ReVelle, C. S., & Eiselt, H. A. (2005). Location analysis: A synthesis and survey. European Journal of Operational Research, 165(1), 1–19.

Rohmer, S. U. K., Gerdessen, J. C., & Claassen, G. D. H. (2019). Sustainable supply chain design in the food system with dietary considerations: A multi-objective analysis. European Journal of Operational Research, 273(3), 1149–1164.

Sachan, A., Sahay, B. S., & Sharma, D. (2005). Developing Indian grain supply chain cost model: A system dynamics approach. International Journal of Productivity and Performance Management, 54(3), 187–205.

Sharon, M., Abirami, C. V., & Alagusundaram, K. (2014). Grain storage management in India. Journal of Postharvest Technology, 2(1), 12–24.

Sheane, R., McCosker, C., & Royston, S. (2018). Report of Food system framework: A focus on food sustainability.

Shukla, M., & Jharkharia, S. (2013). Agri-fresh produce supply chain management: A state-of-the-art literature review. International Journal of Operations & Production Management, 33(2), 114–158.

Soleimani, H., & Kannan, G. (2015). A hybrid particle swarm optimization and genetic algorithm for closed-loop supply chain network design in large-scale networks. Applied Mathematical Modelling, 39(14), 3990–4012.

Song, M., Wang, S., & Fisher, R. (2014). Transportation, iceberg costs and the adjustment of industrial structure in China. Transportation Research Part D: Transport and Environment, 32, 278–286.

Soto-Silva, W. E., Nadal-Roig, E., González-Araya, M. C., & Pla-Aragones, L. M. (2016). Operational research models applied to the fresh fruit supply chain. European Journal of Operational Research, 251(2), 345–355.

Soysal, M., Bloemhof-Ruwaard, J. M., & Van Der Vorst, J. G. A. J. (2014). Modelling food logistics networks with emission considerations: The case of an international beef supply chain. International Journal of Production Economics, 152, 57–70.

Timperley, J. (2019). The carbon brief profile: India. Retrieved August 14, 2019, from https://www.carbonbrief.org/the-carbon-brief-profile-india.

Validi, S., Bhattacharya, A., & Byrne, P. J. (2014). A case analysis of a sustainable food supply chain distribution system—A multi-objective approach. International Journal of Production Economics, 152, 71–87.

Validi, S., Bhattacharya, A., & Byrne, P. J. (2018). Sustainable distribution system design: A two-phase DoE-guided meta-heuristic solution approach for a three-echelon bi-objective AHP-integrated location-routing model. Annals of Operations Research. https://doi.org/10.1007/s10479-018-2887-y.

Veeramachaneni, K., Peram, T., Mohan, C., & Osadciw, L. A. (2003). Optimization using particle swarms with near neighbor interactions. In Genetic and evolutionary computation conference (pp. 110–121). Springer, Berlin.

Vlajic, J. V., Van der Vorst, J. G., & Haijema, R. (2012). A framework for designing robust food supply chains. International Journal of Production Economics, 137(1), 176–189.

Wang, F., Lai, X., & Shi, N. (2011). A multi-objective optimization for green supply chain network design. Decision Support Systems, 51(2), 262–269.

Wang, X., Li, D., & Shi, X. (2012). A fuzzy model for aggregative food safety risk assessment in food supply chains. Production Planning & Control, 23(5), 377–395.

Wisittipanich, W., & Hengmeechai, P. (2017). Truck scheduling in multi-door cross docking terminal by modified particle swarm optimization. Computers & Industrial Engineering, 113, 793–802.

Xu, J., Yan, F., & Li, S. (2011). Vehicle routing optimization with soft time windows in a fuzzy random environment. Transportation Research Part E: Logistics and Transportation Review, 47(6), 1075–1091.

Yakavenka, V., Mallidis, I., Vlachos, D., Iakovou, E., & Eleni, Z. (2019). Development of a multi-objective model for the design of sustainable supply chains: The case of perishable food products. Annals of Operations Research. https://doi.org/10.1007/s10479-019-03434-5.

Yamada, T., & Febri, Z. (2015). Freight transport network design using particle swarm optimisation in supply chain-transport supernetwork equilibrium. Transportation Research Part E: Logistics and Transportation Review, 75, 164–187.

Zhao, X., & Dou, J. (2011). A hybrid particle swarm optimization approach for design of agri-food supply chain network. In 2011 IEEE international conference on service operations, logistics, and informatics (SOLI) (pp. 162–167).

Zhu, Z., Chu, F., Dolgui, A., Chu, C., Zhou, W., & Piramuthu, S. (2018). Recent advances and opportunities in sustainable food supply chain: A model-oriented review. International Journal of Production Research, 56(17), 5700–5722.

Zhu, Y., Ge, H., & Zhen, T. (2009). Hybrid particle swarm algorithm for grain logistics vehicle routing problem. In 3rd International symposium on intelligent information technology application, IITA 2009, (Vol. 2, pp. 364–367).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

1.1 Indices

- \( p \) :

-

Index for procurement centres, p = 1,2,…, P

- \( b \) :

-

Index for a potential location of base silos, b = 1,2,…, B

- \( f \) :

-

Index for a potential location of field silos, f = 1,2,…, F

- \( r \) :

-

Index for regional warehouse, r = 1,2,…, R

- \( d \) :

-

Index for destination warehouse, d = 1,2,…, D

- \( t \) :

-

Index for time period t = 1,2,…, T

- h :

-

Index for capacity of base silo, h = 1,2,…, H

- j :

-

Index for capacity of field silo, j = 1,2,…, J

- \( n_{1} \) :

-

Index for truck type present at procurement centre, \( n_{1} \)= 1,2,…, \( N_{1} \)

- \( n_{2} \) :

-

Index for rake type present at base silo, \( n_{2} \)= 1,2,…, \( N_{2} \)

- \( n_{3} \) :

-

Index for truck type present at field silo, \( n_{3} \)= 1,2,…, \( N_{3} \)

- \( n_{4} \) :

-

Index for truck type present at regional warehouse, \( n_{4} \)= 1,2,…, \( N_{4} \)

1.2 Model parameters

1.2.1 Cost parameters

- \( F_{b}^{h} \) :

-

Fixed cost of establishing the base silo with capacity h at location b

- \( F_{f}^{j} \) :

-

Fixed cost of establishing the field silo with capacity j at location f

- \( tc_{pb} \) :

-

Transportation cost from procurement centre p to base silo b (per MT per km)

- \( tc_{bf} \) :

-

Transportation cost from base silo b to field silo f (per MT per km)

- \( tc_{fr} \) :

-

Transportation cost from field silo f to regional warehouse r (per MT per km)

- \( tc_{rd} \) :

-

Transportation cost from regional warehouse r to destination warehouse d (per MT km)

- \( ih_{b} \) :

-

Inventory holding cost at base silo b (per MT per period)

- \( ih_{f} \) :

-

Inventory holding cost at field silo f (per MT per period)

- \( ih_{r} \) :

-

Inventory holding cost at regional warehouse r (per MT per period)

- \( lc \) :

-

Food grain lost cost (per MT)

- \( ce \) :

-

Cost of ton of carbon dioxide emission

- \( rc \) :

-

Risk penalty cost

1.2.2 Distance parameters

- \( dis_{pb} \) :

-

Distance between procurement centre p to base silo b

- \( dis_{bf} \) :

-

Distance between base silo b to field silo f

- \( dis_{fr} \) :

-

Distance between field silo f to regional warehouse r

- \( dis_{rd} \) :

-

Distance between regional warehouse r to destination warehouse d

1.2.3 Vehicle related parameters

- \( cv_{{n_{1} }} \) :

-

Capacity of truck type \( n_{1} \)

- \( cv_{{n_{2} }} \) :

-

Capacity of rake type \( n_{2} \)

- \( cv_{{n_{3} }} \) :

-

Capacity of truck type \( n_{3} \)

- \( cv_{{n_{4} }} \) :

-

Capacity of truck type \( n_{4} \)

- \( nv_{{n_{1} p}}^{t} \) :

-

Total number of \( n_{1} \) type trucks available at procurement centre p in period t

- \( nv_{{n_{2} b}}^{t} \) :

-

Total number of \( n_{2} \) type rakes available at base silo b in period t

- \( nv_{{n_{3} f}}^{t} \) :

-

Total number of \( n_{3} \) type trucks available at field silo f in period t

- \( nv_{{n_{4} r}}^{t} \) :

-

Total number of \( n_{4} \) type trucks available at regional warehouse r in period t

1.2.4 Procurement, demand, capacity and percentage of loss parameters

- \( A_{p}^{t} \) :

-

Amount of food grain quantity available at procurement centre p in period t

- \( L_{d}^{t} \) :

-

Demand of food grain of destination warehouse d in period t

- \( cb_{h} \) :

-

Capacity of base silo type h

- \( cf_{j} \) :

-

Capacity of field silo type j

- \( cr_{r} \) :

-

Capacity of regional warehouse r

- \( lb \) :

-

Transit loss of food grain if transported in bulk form

- \( lj \) :

-

Transit loss of food grain if transported using conventional way of jute bags

- \( ls \) :

-

Storage loss of food grain if stored in silos

- \( lw \) :

-

Storage loss of food grain if stored in conventional warehouses

1.2.5 Emission parameters

- \( e_{pb}^{{n_{1} }} \) :

-

Amount of CO2 released per unit distance for each \( n_{1} \) type of truck travelling from procurement centre p to base silo b

- \( e_{bf}^{{n_{2} }} \) :

-

Amount of CO2 released per unit distance for each \( n_{2} \) type of rake travelling from base silo b to field silo f

- \( e_{fr}^{{n_{3} }} \) :

-

Amount of CO2 released per unit distance for each \( n_{3} \) type of truck travelling from field silo f to regional warehouse r

- \( e_{rd}^{{n_{4} }} \) :

-

Amount of CO2 released per unit distance for each \( n_{4} \) type of truck travelling from regional warehouse r to destination warehouse d

1.2.6 Risk related parameters

- \( \varepsilon_{b}^{h} \) :

-

Establishment risk of locating base silo with size h at potential location b

- \( \varepsilon_{f}^{j} \) :

-

Establishment risk of locating field silo with size j at potential location f

- \( g_{pb} \) :

-

Risk of transportation between procurement centre p to base silo b

- \( g_{bf} \) :

-

Risk of transportation between base silo b to field silo f

- \( g_{fr} \) :

-

Risk of transportation between field silo f to regional warehouse r

- \( g_{rd} \) :

-

Risk of transportation between regional warehouse r to destination warehouse d

1.3 Decision variables

1.3.1 Binary variables

- \( X_{b}^{h} \) :

-

1, if base silo type h is selected to be established at location b

0 Otherwise

- \( X_{f}^{j} \) :

-

1, if field silo type j is selected to be established at location f

0 Otherwise

- \( Y_{pb}^{t} \) :

-

1, if procurement centre p is assigned to base silo b in time period t

0, Otherwise

- \( Y_{bf}^{t} \) :

-

1, if base silo b is assigned to field silo f in time period t

0, Otherwise

- \( Y_{fr}^{t} \) :

-

1, if field silo f is assigned to regional warehouse r in time period t

0, Otherwise

- \( Y_{rd}^{t} \) :

-

1, if regional warehouse r is assigned to destination warehouse d in time period t

0, Otherwise

1.3.2 Continuous variables

- \( U_{pb}^{t} \) :

-

Shipment quantity from procurement p to base silo b in period t

- \( U_{bf}^{t} \) :

-

Shipment quantity from base silo b to field silo f in period t

- \( U_{fr}^{t} \) :

-

Shipment quantity from field silo f to regional warehouse r in period t

- \( U_{rd}^{t} \) :

-

Shipment quantity from regional warehouse r to destination warehouse d in period t

- \( Tl_{pb}^{t} \) :

-

Fraction of shipment quantity that loss from procurement p to base silo b in period t

- \( Tl_{bf}^{t} \) :

-

Fraction of shipment quantity that loss from base silo b to field silo f in period t

- \( Tl_{fr}^{t} \) :

-

Fraction of shipment quantity that loss from field silo f to regional warehouse r in period t

- \( Tl_{rd}^{t} \) :

-

Fraction of shipment quantity that loss from regional warehouse r to destination warehouse d in period t

- \( IN_{b}^{t} \) :

-

Inventory in base silo b at the end of period t

- \( IN_{f}^{t} \) :

-

Inventory in field silo f at the end of period t

- \( IN_{r}^{t} \) :

-

Inventory in regional warehouse r at the end of period t

- \( Sl_{b}^{t} \) :

-

Fraction of inventory stock that loss in period t at base silo b

- \( Sl_{f}^{t} \) :

-

Fraction of inventory stock that loss in period t at field silo f

- \( Sl_{r}^{t} \) :

-

Fraction of inventory stock that loss in period t at regional warehouse r

1.3.3 Integer variables

- \( V_{pb}^{{n_{1} t}} \) :

-

Number of \( n_{1} \) type of vehicles used from procurement centre p to base silo b in time period t

- \( V_{bf}^{{n_{2} t}} \) :

-

Number of \( n_{2} \) type of rakes used from base silo b to field silo f in time period t

- \( V_{fr}^{{n_{3} t}} \) :

-

Number of \( n_{3} \) type of vehicles used from field silo f to regional warehouse r in time period t

- \( V_{rd}^{{n_{4} t}} \) :

-

Number of \( n_{4} \) type of vehicles used from regional warehouse r to destination warehouse d in time period t

Rights and permissions

About this article

Cite this article

Mogale, D.G., Kumar, S.K. & Tiwari, M.K. Green food supply chain design considering risk and post-harvest losses: a case study. Ann Oper Res 295, 257–284 (2020). https://doi.org/10.1007/s10479-020-03664-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-020-03664-y