Abstract

Multistage modification of commercially available styrene with divinylbenzene (St-DVB) microspheres is presented. The new type of modification introducing very attractive thiol (–SH) groups on the surface of polymeric matrices was made. In order to obtain thiol derivatives, the parent St-DVB microspheres were treated by H2SO4 with addition of oleum and then conversion of sulfonic groups to chloride acylsulfonic groups in the presence of PCl5 and POCl3 was carried out. Finally, the reduction of modified microspheres by using SnCl2·2H2O was conducted. The thiol groups content (elemental analysis), thermal properties (TG/DTG, DSC analysis) as well as the swelling characteristics of the functional microspheres were examined. The novel material St-DVB-SH was compared with commercial ion exchanger Ambersept GT74 to removal of heavy metal ions: Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II). In order to investigate the applicability of the obtained microspheres for heavy metal ions removal, the batch method was used. On the basis of studies, the optimal pH of the solution and microspheres dose was determined. Both for St-DVB-SH and Ambersept GT74, the Langmuir and Freundlich isotherm models are used to represent adsorption equilibria. The pseudo first order, pseudo second order and intraparticle diffusion kinetic models were used to fit the adsorption kinetic data. Additionally, dynamic adsorption tests were carried out in order to establish bed exhaustion. Results of a comprehensive comparative analysis indicate that the new synthesized material St-DVB-SH is very effective for removal of heavy metal ions studied.

Similar content being viewed by others

1 Introduction

Due to the rapid development of the industrial world, there is a significant increase of environmental pollution by heavy metals such as: Hg, Cd, Pb, Co, Zn, Cu. Their harmfulness consists in the possibility of accumulation in living organisms and their chronic toxicity. Health effects of regular consumption of even trace amounts of heavy metals can appear after a long period of time (Guo et al. 2017; Gode and Pehlivan 2006; Mustafa and Komatsu 2016; Hubicki and Kołodyńska 2012; Hubicki et al. 1999; Carolin et al. 2017). There are many different methods of wastewater treatment containing heavy metal ions. Among others, coagulation, solvent extraction, chemical precipitation, electrolysis, membrane separation, ultrafiltration, adsorption, ion exchange and electrodialysis can be distinguished (Fang et al. 2018; Ko et al. 2017; Huang et al. 2016). Adsorption and ion exchange operations are commonly used with applications such as industrial pollution control or environmental protection, especially in water softening, purification and decontamination. The costs for the ion exchange systems will vary depending on (i) discharge requirements, (ii) volume of water to be treated, (iii) contaminant concentration, (iv) presence of other contaminants, (v) ion exchanger and regenerate utilization etc.

Technical products of most importance are styrene-co-divinylbenzene (St-DVB) copolymers and acrylate or methacrylate copolymers with adequate cross-linking agents. The structure of the exchanger is dependent on: (i) the degree of cross linking, (ii) type of cross linking agent, (iii) species of inert material and their ratio during polymerization as well as (iv) stabilizers such as styrene-maleic anhydride copolymers, allyl alcohol and vinyl acetate copolymers, polyvinyl alcohol, sodium polymethacrylate, methylcellulose, carboxymethylcellulose, gelatin and starch (Ozkan et al. 2017; Fang et al. 2014; Galadzhev et al. 2012; Roy et al. 2004). Sometimes inorganic stabilizers as calcium and magnesium hydroxides, talc, alkali silicates and calcium phosphate are used. It is well known that copolymers with the gel structure with low crosslinkage are characterized by no definite pore size and therefore the measurements both pore and volume size as well as inner surface is impossible. Such matrix is also characterized by the difficulty of swelling in order to introduce functional groups. Copolymers with the gel structure contain approx. 2–16% DVB. However, they are not sufficiently effective in many industrial processes because they exhibit unsatisfactory ion exchange rate and have low sorption ability.

Synthesis of the macroporous structure during polymerization process results to the distance formation among the functional groups. Formation of caverns and channels, their amount and size depend on the inert material (pore-forming solvents) used to expand the matrix such as ethanol, toluene, xylene etc. (Mahfouz et al. 2014; Ali et al. 2016). The main factor influencing the developing the inner surface area is application of crosslinkers. The higher the degree of crosslinkage, the larger is the surface. Consequently, ion exchangers with surface area larger than 750 m2/g can be produced by using typical crosslinkers like divinylbenzene (Maciejewska 2012).

Nowadays, the majority of produced the ion-exchange resins are based on the polymer chemistry of styrene (St) crosslinked with divinylbenzene (DVB). The copolymers of St-DVB have well-defined porous structures which make them subject of numerous studies. Furthermore, these materials are mechanically resistant, insoluble in water and strong organic solvents. These copolymers are widely used as ion exchange resins, polymer supported catalysts, precursors for carbon spheres, absorbents and gel permeation chromatography column packings (Fontanals et al. 2015; Bing et al. 2016; Tan and Tan 2017; Tsyurupa and Davankov 2006; Perez-Macia et al. 2015; Podkościelna and Kołodyńska 2013). The diversity of applications is due to modification of the polymer backbone with appropriate ionic functional groups (e.g. sulfonate, acetate, thiol, amine) etc. The cation exchangers with the sulfur atom at varied degree of oxidation state or sulfur atom directly bonded to the benzene ring have the following functional groups: (i) sulfonic, (ii) a sulfinic, (iii) thiol and (iv) isothiourea. In the case of the St-DVB copolymers, the –SO3H groups attached to the benzene rings in an aqueous medium are dissociated and strongly acidic (Bogoczek and Kociołek-Balawejder 1987). In the pH range 2–14 they act as cation exchangers with the capacity 4.2–5.0 mval/g. In contrast, the –SO2H groups attached to the benzene rings are characterized by the average degree of acidity and they are very easily oxidized. These cation exchangers exhibit particularly high affinity for the Pb(II) ions, therefore they are highly selective for them and characterized by good reversibility in the sorption–desorption process. Moreover, copolymers containing the –SOH groups are highly reactive and can be used for the preparation of sulfene derivatives and sulfene cations (Bogoczek and Kociołek-Balawejder 1986, 1987).

Lately, a lot of attention is devoted to polymers containing thiol groups that can be used as selective sorbents for removal of heavy metal ions and other elements in the water and wastewater treatment processes (Zhang et al. 2013; Odio et al. 2016; Abadast et al. 2017; Huang et al. 2017). Thiol groups have a higher affinity to ions of Hg(II), Au(I) and Ag(I) than to the other heavy metal ions, such as Cd(II), Zn(II), Cu(II) or As(III). An example of the ion exchanger containing the thiol groups is Ambersep GT74 (Vudama and Chakraborty 2016). It is a weakly acidic cation exchanger with good selectivity for mercury, rhodium, cadmium, silver, lead and copper. Ambersep GT74 has been designed for the removal of Hg(II) from different solutions. This resin is insoluble in ordinary solvents and stable throughout the pH range. The matrix of this resin is macroporous styrene copolymer. The ionic form as shipped is H+. Ambersep GT74 is used in various fields, including waste water treatment, recovery of solutions and metals, removal of interfering ions in hydrometallurgy and the recovery of the catalysts (WHO Regional Office for Europe 2007). However, the most known is macroporous Imac TMR comprising two functional groups: thiol group and sulfonic acid groups.

In the presented paper, multistage modification of commercially available styrene divinylbenzene (St-DVB) microspheres is presented. The new type of modification introducing very attractive thiol (–SH) groups on the surface of polymeric matrices was made. In order to obtain thiol derivatives the parent St-DVB microspheres were treated by H2SO4 with addition of oleum and then conversion of sulfonic groups to chloride acylsulfonic groups in the presence of PCl5 and POCl3 was carried out. Finally, the reduction of modified microspheres by using SnCl2·2H2O was conducted. The obtained novel material based on the St-DVB with the thiol functional groups St-DVB-SH was compared with commercial ion exchanger Ambersept GT74 which is recommended for removal of heavy metal such ions as Hg(II), Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II).

2 Experimental

2.1 Chemicals and eluents

Commercial St-DVB microspheres were used without any purification. Reagent grade, hydrochloric acid, NaOH, PCl5, POCl3, CH3COOH, SnCl2⋅2H2O, sulfuric(VI) acid, oleum (fuming sulfuric acids), acetone, methanol, hexane, toluene, tetrahydrofuran (THF) and acetonitrile were from Avantor Performance Materials Poland. The initial solutions of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) (1000 mg/L) were prepared by dissolving appropriate amounts of CuCl2∙2H2O, ZnCl2, Cd(NO3)2∙4H2O, Pb(NO3)2 and NiCl2∙6H2O in deionized water. Then they were diluted to obtain 0.001 M, 0.002 and 0.003 M solution of the appropriate ions at relevant pH. 0.1 M HCl or 0.1 M NaOH solutions was used to adjust pH. The solution of NaNO3 was of analytical grade.

2.2 Modification of St-DVB microspheres

2.2.1 Sulfonation of St-DVB microspheres

In a 500 mL round-bottomed three-necked flask, equipped with a mechanical stirrer, thermometer and dropping funnel, 50 g of microspheres (St-DVB) was placed and next a solution of 300 mL of H2SO4 and 60 mL of oleum (65%) were added very slowly and the whole content were stirred for 1.5 h at 50 °C, next for 3 h at 110 °C and finally for 15 h at room temperature. The obtained modified microspheres were transferred to a glass beaker with ice (1 h), next filtered off and washed with distilled water. The course of the reaction was confirmed by determining the acid number (AN) LAN = 4 mmol/g.

2.2.2 Modification II (–SO3Na groups)

Microspheres obtained in reaction of sulfonation (Sect. 2.2.1) were placed together with solution of NaOH (20 g of NaOH and 1 L of water) into a glass beaker. After 3 h the microspheres are filtered and air-dried.

2.2.3 Modification III (–SO2Cl groups)

Ninety five gram of microspheres with –SO3Na groups, 160 g of powdered PCl5, 200 mL of POCl3 were placed in a 500 mL round-bottomed two-necked flask equipped with a thermometer and air condenser. The reaction was performed for 5 h at 110 °C. Next, modified microspheres with –SO2Cl groups on the surface were very slowly transferred to a glass beaker (2.5 L) with ice. After 0.5 h microspheres were filtered off, washed with water and dried in air. Weight of dry microspheres was 90 g.

2.2.4 Modification IV (–SH groups)

200 g SnCl2⋅2H2O and 700 mL CH3COOH were placed in a 1000 mL round-bottomed three-necked flask equipped with a mechanical stirrer, thermometer and glass tube (through which hydrogen chloride was added). The flask was placed in an ice bath and hydrogen chloride was dosed until the reducing mixture was clear. Next, 90 g of selected microspheres (St-DVB-SO2Cl) was placed to the reducing mixture and the whole content was stirred for 5 h. The modified microspheres were left in the flask for 12 h at room temperature. Next, the mixture was heated to 60 °C for 1 h. After this time, microspheres were washed with water in a glass beaker to which 200 mL of HCl was next added. After 0.5 h, microspheres were filtered off, washed with water and dried at 50 °C for 3 h (Podkościelna and Kołodyńska 2013; Podkościelna et al. 2014; Podkościelna 2013).

In the result the new microspheres with very attractive thiol (–SH) groups on the surface of polymeric matrices were made.

2.3 Polymer characterization

Elemental analysis of the modified copolymers was carried out using the Perkin-Elmer CHN 2400 apparatus and elemental analyser Vario EL III Elementar (S).

The KOH/CH3OH method was used to determine the acid number (AN). The acid number content was calculated from the difference between the blank and that found for the titration of the sample reaction mixture.

Attenuated total reflectance (ATR-IR) spectra were obtained using a Bruker FTIR spectrophotometer TENSOR 27. The spectra were in the spectral region of 400–4000 cm−1. The resolution was set to 4 cm−1 and the number of scans per spectrum was equal to 32.

Differential scanning calorimetry (DSC) thermograms were obtained with the use of a DSC Netzsch 204 calorimeter (Netzsch, Günzbung, Germany). All DSC measurements were carried out in aluminium pans with a pierced lid with the sample weight ~ 5–10 mg under nitrogen atmosphere (30 mL/min). Dynamic scans were performed at a heating rate of 10 K/min in the temperature range 20–450 °C. Curing characteristics, such as temperature of the peak maximum and final cure temperature were determined.

The thermogravimetric analysis (TG/DTG) was made on a STA 449 Jupiter F1, Netzsch (Germany). The samples were heated from 20 to 1000 °C with a heating rate of 10 °C/min under a dynamic atmosphere of helium (40 mL/min).

Image of microspheres was made using the optical microscope MORPHOLOGI G3 Malvern (Great Britain).

2.4 Kinetic, equilibrium and dynamic adsorption studies

Batch experiments were conducted using 250 mL flask kept at a constant temperature (20 °C) for a period of up to 2 h shaking. For this aim mechanical shaker ELPIN type 357 (Poland) was used. The reaction mixture consisted of 0.5 g of St-DVB-SH or Ambersep GT74 and a known initial concentration of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) in a total volume of 100 mL. All the adsorption experiments were in 0.01 M NaNO3 background electrolyte to maintain a constant ionic strength. The desired pH was adjusted before the experiments. After the appropriate time (1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 60 and 120 min.) or after the reaching equilibrium, the adsorbent was removed by filtration using filtering paper. The concentration of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions was determined by AAS method using AAS 240 FS spectrometer (Varian) at 324,7 nm for Cu(II), 213,9 nm for Zn(II), 228,8 nm for Cd(II), 217 nm for Pb(II) and 232 nm for Ni(II).

The adsorption capacity at time t (qt) and adsorption percentage (S%) were calculated according to Eqs. 1 and 2 (An et al. 2017).

where: qt is the adsorption amount of M(II) ions at time t (mg/g), c0 is the initial concentration of M(II) in the solution (mg/L), ct is the concentration of M(II) at time t (mg/L), V is the volume of solution (L), m is the weight of St-DVB-SH or Ambersept GT74 sample (g), S% is the adsorption percentage (%).

The pseudo first order (PFO), pseudo second order (PSO) and intraparticle diffusion (IPD) kinetic models were used to fit the adsorption kinetic data. They are expressed as:

-

(a)

The pseudo first order (PFO):

$$\log \left( {{q_1} - {q_t}} \right)=\log \left( {{q_1}} \right) - \frac{{{k_1}t}}{{2.303}}$$(3) -

(b)

Pseudo second order (PSO):

$$\frac{t}{{{q_t}}}=\frac{1}{{{k_2}q_{2}^{2}}} - \frac{t}{{{q_2}}}$$(4) -

(c)

Intraparticle diffusion model (IPD):where:

$${q_t}={k_i}{t^{0.5}}+C$$(5)

q1,q2 are the amounts of adsorbed metal ions at equilibrium, qt is defined as previously, k1 is the pseudo first order rate constant (1/min), k2 is the pseudo second order rate constant (g/mg/min), ki is the intraparticle diffusion rate constant (mg/g/min0.5), C is the diffusion constant. Additionally from PSO model the initial sorption rate constant h was calculated.

The isotherms of equilibrium adsorption of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions on St-DVB-SH and Ambersep GT74 were analyzed by means of the Langmuir and Freudlich models:

-

(a)

Langmuir model

$$\frac{1}{{{q_e}}}=\frac{1}{{{q_m}{K_L}{c_e}}}+\frac{1}{{{q_m}}}$$(6) -

(b)

Freundlich model

$$\log {q_e}=\log {K_F}+\frac{1}{n}\log {c_e}$$(7)

where: qe is the amount of adsorbed metal ions at equilibrium, KL is the Langmuir constant, qm is the adsorption capacity of the ion exchanger and Ce is the equilibrium concentration of metal ions in the solution; KF is the multilayer sorption capacity of sorbent, 1/n is the Freundlich constant.

Dynamic adsorption tests were carried out for St-DVB-SH and Ambersep GT74 in order to establish bed exhaustion. Breakthrough curves were plotting as C/C0 versus Ve, where C0 is the inlet concentration of metal ions (mg/L) and C is the outlet concentration of metal ion (mg/L), Ve is the outlet fraction volume.

3 Results and discussion

3.1 Properties of the St-DVB microspheres

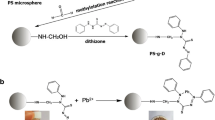

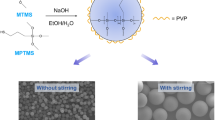

Figure 1 presents the scheme of modification of commercially available St-DVB microspheres. In a four-step modification, St-DVB microspheres with –SH functional groups were obtained. In Fig. 2 the image of microspheres after modification is presented. Some microspheres have damages in form of cracks caused by relatively hard reaction conditions. Elemental analysis confirms the presence of thiol groups on the surface of microspheres. The results show that after modification, 12.94% of the sulfur in form of thiol groups was introduced into the polymeric matrix. This confirms that the proposed modifications are very efficient.

The tendency to swell is an important parameter which determines the use of polymeric microspheres as a sorbents in different solvents. In order to define the tendency to swell, the swellability coefficient (B) was determined. B is a function of the solvent nature and composition of the copolymers. B was defined by equilibrium swelling in acetone, methanol, acetonitrile, toluene, hexane, THF and water (Tuncel and Piskin 1996; Kesenci et al. 1996). Swellability coefficient is expressed as:

where: Vs is the volume of the copolymer after swelling, Vd is the volume of the dry copolymer.

0.1 g of the sample was transferred into a glass tube (ø 1 cm) with a sinter and immersed in 2 mL of the solvent. Before and after swelling, the volume of the sorbent in the glass tube was measured. Three specimens were tested for each samples and a mean value was taken. The values of B for microspheres vary from 0 to 12% (Table 1). In nonpolar solvents (toluene, hexane) copolymers practically not swell. After modification polymers exhibit a slight increase of swelling in polar solvents such as acetone (increase from 4 to 8%), in methanol from 2 to 4% and acetonitrile from 2 to 5%, with the exception of water when the increase of swelling about 12% is observed.

Thermal properties of copolymers were characterized by DSC analysis. The DSC curves are shown in Fig. 3. The obtained results in the range from 25 to 500 °C are measured. The presented curves for parent microspheres (St-DVB) and modified ones with -SH groups (St-DVB-SH) have a different course. Starting material is stable up to 350 °C. On the curve only one endothermic effect at maximum at 421.5 °C, connected with the thermal degradation of copolymer is visible. The glass transition temperature can be observed at 105–107 °C, which corresponds to the glass transition temperature of polystyrene (Rieger 1996; Ahmed et al. 2017). After modification with thiol groups, the thermal resistance of microspheres is lowered. On the curve, two endothermic effects are noticable. The first at 175.2 °C is probably associated with cleavaging/disconnection of thiol groups. The second one at 299.6 °C is associated with the partial thermal degradation of the sample.

In order to determine of thermal stability of sorbents the TG and DTG measurements in inert atmosphere (helium) were made. Figure 4 presents the analysis for commercial St-DVB copolymer. It is clearly visible that the commercial sorbent decomposed in one step with the maximum at 420 °C and it is related to the total degradation of aromatic fragments. A completely different course have curves (Fig. 5) for the copolymer with thiol groups. Due to the small weight loss of the St-DVB-SH, sample was heated from 20 to 1000 °C. From the course of TG curve one can see that the process of destruction of the sample, after reaching the temperature of 1000 °C (with a heating rate of 10 °C/min) has not been completed. About 40% of residue of the starting mass of the sample was obtained, probably in the form of difficult to decompose aromatic-sulfur connections. The lower thermal resistance of the sorbents after modification can be related to the partial destruction (cracking) of the microspheres (Fig. 2) due to the drastic synthesis conditions. This results in a faster thermal degradation of the modified sorbents. Nevertheless, this thermal resistance is sufficient for the sorption process. Figure 6 show the ATR-FTIR spectra of two studied ion exchangers: St-DVB-SH and Ambersep GT-74. In the both spectra, the presence of intensive peak located at 3450 cm−1 can be assigned to the O–H bands. This peak is connected with presence of hydroscopic water in macroporous structure of polymeric beads. The signals located at 2920–2875 cm−1 are derived from the stretching vibrations of aromatic and aliphatic –CH, –CH2 groups. The aromatic group C=C gives a shape signal at 1620 cm−1. The signals about 830 cm−1 can be assigned to the C–H vibrations from the benzene ring. The small typical signals at 2300 cm−1 are derived from thiol (–SH) groups.

3.2 Studies of kinetics and equilibrium adsorption

After estimation of the optimum sorbent mass from the range 0.05–0.1 g of the each ion exchanger St-DVB-SH and Ambersep GT74 (data not presented) the sorption process was carried out for the concentrations in the range 0.001–0.003 M of the initial solution of the above-mentioned ions, weight of 0.1 g (as the optimal), shaking speed of 180 rpm and at temperature of 293 K (Figs. 7a–f, 8a–f, 9a–f). The next tests were carried out to determine the optimal pH of the solution for sorption of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions on the St-DVB-SH and Ambersep GT74. It is well-known that in the solution copper(II) in the pH range from 1 to 7 occurs as Cu2+ cation. In the pH range 6–10 there are other cationic forms CuOH+ and Cu2(OH)22+. At higher pH values i.e. in the range of 7–12, precipitation of copper(II) hydroxide occurs. Above pH 9, anionic forms Cu(OH)3− and Cu(OH)42−, dominate. As for zinc(II), up to pH 8 it is in the form of Zn2+ cation. The precipitation of the amphoteric zinc hydroxide(II) starts at pH 8. At pH 10 there are also the co-existing anionic forms, i.e. Zn(OH)3− and Zn(OH)42−. Cadmium and lead also exist as Cd2+ and Pb2+ ions. In literature it has been mentioned (Carolin et al. 2017; Fang et al. 2018; Hubicki et al. 1999) that prevalence of free cadmium ions at pH below 8 after which hydroxyls are formed. Lead also precipitates at pH 8. Cationic combinations of PbOH+ and Pb3(OH)42+ are also formed at pH in the range of 6–12. A small percentage of the Pb2OH3+ cation exists at pH from 7 to 9. Pb(OH)2 hydroxide inclusions occur in the pH range of 8–13. The anionic form of Pb(OH)3− occurs at pH 9 and dominates at higher values. Similar behavior is observed in the case of nickel.

The pH value is one of crucial parameters which influence the efficiency of the process of heavy metal ions uptake. Therefore, the pH value of the solution affects the sorption of metal ions and their interactions with the functional groups of St-DVB-SH and Ambersep GT74. Based on the conducted tests, it can be concluded that for St-DVB-SH and Ambersep GT74, the amount of adsorbed ions increases gradually with increasing pH and the highest value reaches at pH 5, therefore this pH value was chosen for further studies on the effect of phase contact time and initial concentration on the sorption process. In addition, the choice of pH 5 for the sorption process is consistent with the speciation of the above-mentioned metal ions as was discussed above. These results confirm the presence of metals in the form of two-positive cations and the lack of other forms that can reduce the effectiveness of the process (precipitation effect).

As for kinetic analysis, it was found that removal of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) on St-DVB-SH and Ambersep GT74 increases with time and reaches a maximum value at about 90 min. Changing the initial concentration metal ions from 0.001 to 0.003 M the amount adsorbed also increases for all metal ions. The pseudo-second kinetic model (PSO) correlates best the uptake rate (R2 > 0.99) and it is important in water treatment process design using St-DVB-SH and Ambersep GT74 (Tables 2, 3). Good fits were observed for all initial concentration of studied metal ions indicating that sorption reaction can be approximated with the second order kinetics model (Figs. 7c,f, 8c, f, 9c,f).

The Langmuir model is widely applied for indicating the adsorption isotherm type. The adsorbate e.g. metal ions adsorbed only on the specific number of sites of ion exchanger are characterized by the same energy of sorption and any interactions between them. The obtained sorption isotherms of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) on St-DVB-SH and Ambersep GT74 at 20, 40 and 60 °C are presented in Fig. 10a–e. The parameters obtained from the isotherm equation are listed in Table 4. Based on the results presented in Table 4, it was found that sorption of Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions in a one component system both on St-DVB-SH and Ambersep GT74 is well described by the Langmuir model. This is confirmed by the high values of the determination coefficients (R2 > 0.997). Additionally, the agreement between the experimental data (qe,exp) and the model predicted values of adsorption capacities (q2 from PSO) was evident. The maximum adsorption capacities of the St-DVB-SH for the Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions are 45.26 mg/g, 32.42 mg/g, 62.77 mg/g, 135.85 mg/g and 49.88 mg/g at a pH of 5, respectively. These values were higher than for commercially available Ambersep GT74. Better results were also obtained for higher temperatures (Fig. 10), except for Ni(II).

In the next step, the results were evaluated by the dynamic method. The performance of a column was evaluated based on the shape of the breakthrough curve obtained from the plot of C/Co vs. Ve. The breakthrough curve of Cu(II), Cd(II) and Ni(II) on St-DVB-SH (closed symbols) and Ambersep GT74 (open symbols) are presented in Fig. 11. As follows from the breakthrough curves, Cu(II), Cd(II) and Ni(II) exhibit higher affinity for the St-DVB-SH than for the corresponding ion exchanger Ambersep GT74. The greatest differentiation in affinity of the metal ions sorption was found on the St-DVB-SH. The shape of the curves for Cu(II), Cd(II) and Ni(II) at pH 5.0 suggests possible separation of these metal ions according to the affinity series: Cd(II) > Cu(II) > Ni(II).

4 Conclusions

A four-step modification of commercial styrene with divinylbenzene (St-DVB) microspheres was carried out in order to obtain novel materials with very attractive thiol functional groups (St-DVB-SH). Elemental analysis confirmed the presence of thiol groups (12.94% of S) on the surface of modified microspheres. The synthesized materials have a low tendency to swell in organic solvents (max 8%). The novel material St-DVB-SH was compared with commercial ion exchanger Ambersept GT74 to removal of heavy metal ions: Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II). Based on the conducted tests, pH 5 was chosen for all adsorption studies which guarantees the presence of metals ions in the form of two-positive cations and the lack of other forms that can reduce the effectiveness of the process. Kinetic studies indicate that efficiency of metal ions removal is greater for St-DVB-SH than for Ambersept GT74. It is particularly evident at higher initial concentrations of 0.002 and 0.003 M. The pseudo-second kinetic model (PSO) correlates best the uptake rate (R2 > 0.99) for both St-DVB-SH and Ambersep GT74. It was found that sorption of metal ions studied is well described by the Langmuir model, which is confirmed by high values of determination coefficients. The maximum adsorption capacities of the St-DVB-SH for the Cu(II), Zn(II), Cd(II), Pb(II) and Ni(II) ions were distinctly higher than for Ambersep GT74. The obtained results and comparative studies with commercial ion exchanger (Ambersep GT74) indicate that the new synthesized St-DVB-SH material can be successfully used for sorption of the heavy metals ions studied.

References

Abadast, F., Mouradzadegun, A., Ganjali, M.R.: Rational design, fabrication and characterization of a thiol-rich 3D-porous hypercrosslink polymer as a new engineered Hg2+ sorbent: enhanced selectivity and uptake. New J. Chem. 41, 5458–5466 (2017)

Ahmed, L., Zhang, B., Hawkins, S., Mannan, M.S., Cheng, Z.: Study of thermal and mechanical behaviors of flame retardant polystyrene-based nanocomposites prepared via in-situ polymerization method. J. Loss Prev. Process Ind. 49, 228–239 (2017)

Ali, S.W., Malik, M.A., Yasin, T.: Economical and environmentally friendly synthesis of strong cation-exchange resins from macroporous styrene-divinylbenzene copolymers. Polym. Bull. 73, 559–570 (2016)

An, F.Q., Wu, R.Y., Li, M., Hu, T.P., Gao, J.F., Yuan, Z.G.: Adsorption of heavy metal ions by iminodiacetic acid functionalized D301 resin: kinetics, isotherms and thermodynamics. React. Funct. Polym. 118, 42–50 (2017)

Bing, Y., Chao, T., Hailin, C., Tao, X.: Synthesis of monodisperse poly(styrene-co-divinylbenzene) microspheres with binary porous structures and application in high-performance liquid chromatography. J. Mater. Sci. 51, 5240–5251 (2016)

Bogoczek, R., Kociołek-Balawejder, E.: Kationit tiofenolowy otrzymany z makroporowatego, sulfonowego kationitu styrenowo-diwinylobenzenowego. Chemia Stosowana 30, 591–602 (1986)

Bogoczek, R., Kociołek-Balawejder, E.: Synteza kationitu sulfinowego z makroporowatego sulfinowego kationitu styreno-diwinylobenzenowego. Polimery-tworzywa wielkocząsteczkowe, 12–15 (1987)

Carolin, C.F., Kumar, P.S., Saravanan, A., Joshiba, G.J., Naushad, Mu: Efficient techniques for the removal of toxic heavy metals from aquatic environment: a review. J. Environ. Chem. Eng. 5, 2782–2799 (2017)

Fang, P., Mao, P.P., Chen, J., Du, Y., Hou, X.: Synthesis and properties of a ternary polyacrylate copolymer resin for the absorption of oil spills. J. Appl. Polym. Sci. 131, 40180 (2014)

Fang, L., Li, L., Qu, Z., Xu, H., Xu, J., Yan, N.: A novel method for the sequential removal and separation of multiple heavy metals from wastewater. J. Hazard. Mater. 342, 617–624 (2018)

Fontanals, N., Marcé, R.M., Borrull, F., Cormack, P.A.G.: Hypercrosslinked materials: preparation, characterisation and applications. Polym. Chem. 6, 7231–7244 (2015)

Galadzhev, S.A., Zuev, S.N., Tsarik, L.Y.: Suspension copolymerization of styrene and divinylbenzene in the presence of stabilizers (starch and gelatin). Russ. J. Appl. Chem. 85, 1631–1635 (2012)

Gode, F., Pehlivan, E.: Removal of chromium(III) from aqueous solutions using Lewatit S100: the effect of pH, time, metal concentration and temperature. J. Hazard. Mater. B 136, 330–337 (2006)

Guo, J., Kang, Y., Feng, Y.: Bioassessment of heavy metal toxicity and enhancement of heavy metal removal by sulfate-reducing bacteria in the presence of zero valent iron. J. Environ. Manage. 203, 278–285 (2017)

Huang, Y., Wu, D., Wang, X., Huang, W., Lawless, D., Feng, X.: Removal of heavy metals from water using polyvinylamine by polymer-enhanced ultrafiltration and flocculation. Sep. Purif. Technol. 158, 124–136 (2016)

Huang, L.J., Peng, C.Y., Cheng, Q., He, M., Chen, B.B., Hu, B.: Thiol-functionalized magnetic porous organic polymers for highly efficient removal of mercury. Ind. Eng. Chem. Res. 56, 13696–13703 (2017)

Hubicki, Z., Kołodyńska, D.: Selective removal of heavy metal ions from waters and waste waters using ion exchange methods. In: Kilislioglu, A. (ed.) Ion Exchange Technologies, pp. 193–240. InTech, London (2012)

Hubicki, Z., Jakowicz, A., Łodyga, A.: Application of the ions from waters and sewages. In: Dąbrowski, A. (ed.) Adsorption and Environmental Protection, Studies in Surface Science and Catalysis, pp. 497–531. Elsevier, Amsterdam (1999)

Kesenci, K., Tuncel, A., Piskin, E.: Swellable ethylene glycol dimethacrylate-hydroxyethylmethacrylate copolymer beads. React. Funct. Polym. 31, 137–147 (1996)

Ko, D., Lee, J.S., Patel, H.A., Jakobsen, M.H., Hwang, Y., Yavuz, C.T., Hansen, H.C., Andersen, H.R.: Selective removal of heavy metal ions by disulfide linked polimer networks. J. Hazard. Mater. 332, 140–148 (2017)

Maciejewska, M.: Characterization of macroporous 1-vinyl-2-pyrrolidone copolymers obtained by suspension polymerization. J. Appl. Polym. Sci. 124, 568–575 (2012)

Mahfouz, M.G., Killa, H.M., Sheta, M.E., Moustafa, A.H., Tolba, A.A.: Synthesis, characterization, and application of polystyrene adsorbents containing tri-n-butylphosphate for solid-phase extraction of uranium(VI) from aqueous nitrate solutions. J. Radioanal. Nucl. Chem. 301, 739–749 (2014)

Mustafa, G., Komatsu, S.: Toxicity of heavy metals and metal-containing nanoparticles on plants. Biochem. Biophys. Acta. 1864, 932–944 (2016)

Odio, O.F., Lartundo-Rojas, L., Palacios, E.G., Martinez, R., Reguera, E.: Synthesis of a novel poly-thiolated magnetic nano-platform for heavy metal adsorption. Role of thiol and carboxyl functions. Appl. Surf. Sci. 386, 160–177 (2016)

Ozkan, G., Ozkan, G., Ince, E., Bildi, O.: Determination of optimal synthesis conditions of porous styrene divinyl benzene copolymer beads in the presence of the ammonia borane. J. Fac. Eng. Archit. Gazi Univ. 32, 1–7 (2017)

Perez-Macia, M.A., Curco, D., Bringue, R., Iborra, M., Rodriguez-Ropero, F., van der Vegt, N.F.A., Aleman, C.: 1-Butanol absorption in poly(styrene-divinylbenzene) ion exchange resins for catalysis. Soft Matter 47, 9144–9149 (2015)

Podkościelna, B.: The use of bis[4(2-hydroxy-3-methacryloyloxypropoxy)phenyl] sulfide in preparation of microspheres with pendant amine groups as a heavy metal sorbent. Sep Sci Technol 48, 1699–1708 (2013)

Podkościelna, B., Kołodyńska, D.: A new type of cation-exchange polymeric microspheres with pendant methylenethiol groups. Polym. Adv. Technol. 24, 866–872 (2013)

Podkościelna, B., Bartnicki, A., Podkościelny, P.: New ion exchangers based on copolymers: 2,3-(2-hydroxy-3-methacryloyloxypropoxy)naphthalene–styrene. Sep. Sci. Technol. 49, 1672–1678 (2014)

Rieger, J.: The glass transition temperature of polystyrene. Results of a round robin test, J. Therm. Anal. 46, 965–972 (1996)

Roy, P.K., Rawat, A.S., Choudhary, V., Rai, P.K.: Synthesis and analytical application of a chelating resin based on a crosslinked styrene/maleic acid copolymer for the extraction of trace- metal ions. J. Appl. Polym. Sci. 94, 1771–1779 (2004)

Tan, L.X., Tan, B.: Hypercrosslinked porous polymer materials: design, synthesis and applications. Chem. Soc. Rev. 46, 3322–3356 (2017)

Tsyurupa, M.P., Davankov, V.A.: Porous structure of hypercrosslinked polystyrene: state-of-the-art mini-review. React. Funct. Polym. 66, 768–779 (2006)

Tuncel, A., Piskin, A.: Nonswellable and swellable poly(EGDMA) microspheres. J. Appl. Polym. Sci. 62, 789–798 (1996)

Vudama, K., Chakraborty, P.: Kinetic speciation of mercury–humate complexes in aqueous solutions by using competing ligand exchange method. Microchem. J. 126, 551–557 (2016)

World Health Organization Regional Office for Europe: Health Risks of: Heavy Metals from Long-range Transboundary Air Pollution. World Health Organization Regional Office for Europe, Copenhagen (2007)

Zhang, S.X., Zhang, Y.Y., Liu, J.S., Xu, Q., Xiao, H.Q., Wang, X.Y., Xu, H., Zhou, J.: Thiol modified Fe3O4 & SiO2 as a robust, high effective and recycling magnetic sorbent for mercury removal. Chem. Eng. J. 226, 30–38 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Podkościelna, B., Kołodyńska, D. & Podkościelny, P. Chemical modification of commercial St-DVB microspheres and their application for metal ions removal. Adsorption 25, 529–544 (2019). https://doi.org/10.1007/s10450-019-00020-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-019-00020-w