Abstract

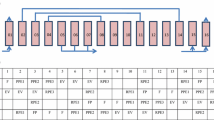

A graphical unit block was used to formulate new PSA cycle schedules that include an unlimited number of equalization steps, no idle steps, no dead time and a minimum number of just three PSA beds assisted with two or more equalization tanks. The approach to designing these PSA cycle schedules is based on three simple rules: (1) restrict the placement of all the equalization steps within the boxes of the PSA cycle schedule to be in sequence with no other cycle steps in between them; (2) place all the equalization steps in the left most boxes of the PSA cycle schedule underneath the Bed 1 feed step with no other cycle steps below them except other equalization steps; and (3) add equalization tanks as needed. These new 3-bed PSA cycle schedules may include any of the common PSA cycle steps in such a way that the equalization steps do not interfere with any of the non-equalization steps affording the non-equalization steps additional degrees of freedom. Since a bed-to-tank-to-bed equalization step may not be as effective as a bed-to-bed equalization step, a forced cocurrent depressurization (CoD) step coupled with an intermediary light end pressurization (LEP) step can be added to this 3-bed PSA cycle schedule. These coupled steps take place after the last of the equalization down and up steps with the aid of a compressor or vacuum pump. Since the utilization of several equalization steps and the utilization of forced CoD/LEP steps may limit the duration of the countercurrent depressurization (CnD) and/or light reflux (LR) steps, one or more additional beds can also be added to this 3-bed PSA cycle schedule. These additional beds increase the durations of the CnD and LR steps without affecting the duration of the feed step. Any combination of these PSA cycle schedule improvements can be used to improve the PSA process performance in terms of capital and operating costs, productivity or throughput, and recovery and purity of the species of interest whether it is the heavier, lighter or both species.

Similar content being viewed by others

Abbreviations

- CnD :

-

Countercurrent depressurization

- CoD :

-

Cocurrent depressurization

- E :

-

Equalization down

- E*:

-

Equalization up

- F :

-

Feed

- HP :

-

Heavy product

- I :

-

Idle

- LEP :

-

Light end pressurization

- LP :

-

Light product

- LPP :

-

Light product pressurization

- LR :

-

Light reflux

References

Baksh, M.S.A., Notaro, F.: Optimal pressure swing adsorption refluxing. US Patent 5,565,018, 1996

Baksh, M.S.A., Notaro, F.: Pressure swing adsorption process and system with segregated product storage tank. European Patent Application EP 0, 753 334 (1997)

Baksh, M.S.A., Rosinski, A.C.: Vacuum pressure swing adsorption process and enhanced oxygen recovery. US Patent 7,763,100, 2010

Baksh, M.S.A., Terbot, C.E.: Pressure swing adsorption process for the production of hydrogen. US Patent 6,503,299, 2003

Doshi, K.J., Patel, K.M.: Pressure swing adsorption recovery. US Patent 4,340,398, 1982

Ebner, A.D., Mehrotra, A., Ritter, J.A.: Graphical approach for complex PSA cycle scheduling. Adsorption. 15, 406–421 (2009)

Ebner, A.D., Mehrotra, A., Ritter, J.A.: Graphical unit block approach for complex PSA cycle scheduling of parallel interacting trains of columns and tanks. Adsorption. 21, 229–241 (2015)

Fuderer, A.: Pressure swing adsorption with direct and indirect pressure equalizations. US Patent 4,468,237, 1984

Kibler, V.J., Schaub, H.R.: Improved pressure swing adsorption process. European Patent Application EP 0 705 636, 1999

Krishnamurthy, R., Lerner, S.L., MacLean, D.L.: PSA multicomponent separation utilizing tank equalization. US Patent 4,816,039, 1989

Lee, H., Stahl, D.E.: Pressure equalization and purging system for heatless absorption systems. US Patent 3,788,036, 1974

Mehrotra, A., Ebner, A.D., Ritter, J.A.: Simplified graphical approach for complex PSA cycle scheduling. Adsorption. 17, 337–345 (2011)

Reinhold, H.E. III, D’Amico, J.S., Knaebel, K.S.: Natural gas enrichment process. US Patent 5,536,300, 1996

Reinhold, H.E. III.: Pressure swing adsorption method for separating gas components. US Patent 7,740,687, 2010

Ritter, J.A., Ebner, A.D., Ho, J.G.S.: Pressure swing adsorption process for enhanced separation of lighter from heavier species. US Patent 9,579,598, 2017

Ruthven, D.M.: Principles of Adsorption and Adsorption Processes. Wiley, New York (1984)

Suh, S.-S., Wankat, P.C.: A new pressure swing adsorption process for high enrichment and recovery. Chem. Eng. Sci. 44, 567–574 (1989)

Xu, J., Weist, E.L. Jr.: Six bed pressure swing adsorption process with four steps of pressure equalization. US Patent 6,454,838, 2002

Funding

The authors gratefully acknowledge financial support provided by Apache Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ebner, A.D., Ho, J.G.S. & Ritter, J.A. Graphical approach for formulating pressure swing adsorption cycle schedules with unlimited equalization steps. Adsorption 24, 221–232 (2018). https://doi.org/10.1007/s10450-018-9934-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-018-9934-5