Abstract

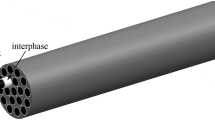

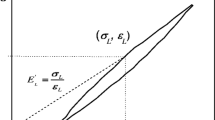

The strength of plain-woven SiC/SiC composites was predicted with the multi-scale method. Firstly, a three-dimensional unit cell was used to characterize the geometric structure of plain-woven SiC/SiC composites. Secondly, the yarns were seen as minicomposites, whose axial mechanical properties were obtained by the shear-lag model, and the fiber defect model was adopted to simulate the failure process of minicomposites. The strength of plain-woven SiC/SiC composites predicted with the multi-scale method is in good agreement with the experimental result. Besides, the effects of heat treatment and load-carrying capacity of broken fiber on the strength of plain-woven SiC/SiC composites were evaluated, and the effect of woven geometry structure was also evaluated.

Similar content being viewed by others

References

Yin, X.W., Cheng, L.F., Zhang, L.T., Travitzky, N., Greil, P.: Fibre-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev. 62(3), 117–172 (2017). https://doi.org/10.1080/09506608.2016.1213939

Meyer, P., Waas, A.M.: FEM predictions of damage in continous fiber ceramic matrix composites under transverse tension using the crack band method. Acta Mater. 102, 292–303 (2016). https://doi.org/10.1016/j.actamat.2015.09.002

Gao, X.G., Zhang, S., Fang, G.W., Song, Y.D.: Distribution of slip regions on the fiber-matrix interface of ceramic matrix composites under arbitrary loading. J. Reinf. Plast. Compos. 34(20), 1713–1723 (2015). https://doi.org/10.1177/0731684415596596

Curtin, W.A.: Theory of mechanical properties of ceramic-matrix composites. J. Am. Ceram. Soc. 74(11), 2837–2845 (1991). https://doi.org/10.1111/j.1151-2916.1991.tb06852.x

Curtin, W.A.: Ultimate strengths of fibre-reinforced ceramics and metals. Composites. 24(2), 98–102 (1993). https://doi.org/10.1016/0010-4361(93)90005-s

Keith, W.P., Kedward, K.T.: The stress-strain behaviour of a porous unidirectional ceramic matrix composite. Composites. 26(3), 163–174 (1995). https://doi.org/10.1016/0010-4361(95)91379-j

Pryce, A.W., Smith, P.A.: Matrix cracking in unidirectional ceramic matrix composites under quasi-static and cycle loading. Acta Metall. Mater. 41(4), 1269–1281 (1993). https://doi.org/10.1016/0956-7151(93)90178-u

Curtin, W.A., Ahn, B.K., Takeda, N.: Modeling brittle and tough stress-strain behavior in unidirectional ceramic matrix composites. Acta Mater. 46(10), 3409–3420 (1998). https://doi.org/10.1016/s1359-6454(98)00041-x

Yang, C.P., Jia, F., Wang, B., Huang, T., Jiao, G.Q.: Unified tensile model for unidirectional ceramic matrix composites with degraded fibers and interface. J. Eur. Ceram. Soc. 39(2–3), 222–228 (2019). https://doi.org/10.1016/j.jeurceramsoc.2018.09.006

Aubard, X., Lamon, J., Allix, O.: Model of the nonlinear mechanical behavior of 2D SiC-SiC chemical vapor infiltration composites. J. Am. Ceram. Soc. 77(8), 2118–2126 (1994). https://doi.org/10.1111/j.1151-2916.1994.tb07106.x

Fagiano, C., Genet, M., Baranger, E., Ladeveze, P.: Computational geometrical and mechanical modeling of woven ceramic composites at the mesoscale. Compos. Struct. 112, 146–156 (2014). https://doi.org/10.1016/j.compstruct.2014.01.045

Ismar, H., Schroter, F., Streicher, F.: Modeling and numerical simulation of the mechanical behavior of woven SiC/SiC regarding a three-dimensional unit cell. Comput. Mater. Sci. 19(1–4), 320–328 (2000). https://doi.org/10.1016/s0927-0256(00)00170-1

Jacobsen, T.K., Brondsted, P.: Mechanical properties of two plain-woven chemical vapor infiltrated silicon carbide-matrix composites. J. Am. Ceram. Soc. 84(5), 1043–1051 (2001). https://doi.org/10.1111/j.1151-2916.2001.tb00788.x

Yang, C.P., Jiao, G.Q., Wang, B., Huang, T., Guo, H.B.: Damage-based failure theory and its application to 2D-C/SiC composites. Compos. Pt. A-Appl. Sci. Manuf. 77, 181–187 (2015). https://doi.org/10.1016/j.compositesa.2015.07.003

Araki, H., Suzuki, H., Yang, W., Sato, S., Noda, T.: Effect of high temperature heat treatment in vacuum on microstructure and bending properties of SiCf/SiC composites prepared by CVI. J. Nucl. Mater. 258, 1540–1545 (1998). https://doi.org/10.1016/s0022-3115(98)00293-1

Zhang, S., Gao, X.G., Song, Y.D.: In situ strength model for continuous fibers and multi-scale modeling the fracture of C/SiC composites. Appl. Compos. Mater. 26(1), 357–370 (2019). https://doi.org/10.1007/s10443-018-9696-y

Zhang, S., Gao, X.G., Dong, H.N., Ju, X.R., Song, Y.D.: In situ modulus and strength of carbon fibers in C/SiC composites. Ceram. Int. 43(9), 6885–6890 (2017). https://doi.org/10.1016/j.ceramint.2017.02.109

Zhang, S., Gao, X., Chen, J., Dong, H., Song, Y., Zhang, H.: Effects of micro-damage on the nonlinear constitutive behavior of SiC/SiC Minicomposites. J. Ceram. Sci. Technol. 7(4), 341–347 (2016). https://doi.org/10.4416/jcst2016-00040

Xia, Z.H., Zhou, C.W., Yong, Q.L., Wang, X.W.: On selection of repeated unit cell model and application of unified periodic boundary conditions in micro-mechanical analysis of composites. Int. J. Solids Struct. 43(2), 266–278 (2006). https://doi.org/10.1016/j.ijsolstr.2005.03.055

Gowayed, Y., Ojard, G., Santhosh, U., Jefferson, G.: Modeling of crack density in ceramic matrix composites. J. Compos. Mater. 49(18), 2285–2294 (2015). https://doi.org/10.1177/0021998314545188

Acknowledgements

This work was supported by the National Key Research and Development Program of China [grant number 2017YFB0703200], the National Natural Science Foundation of China [grant numbers 51575261, 51675266], the Fundamental Research Funds for the Central universities [NF2018002], and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Dong, H., Zhang, S. et al. Multi-Scale Modeling and Experimental Study of the Strength of Plain-Woven SiC/SiC Composites. Appl Compos Mater 26, 1333–1348 (2019). https://doi.org/10.1007/s10443-019-09783-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09783-5