Abstract

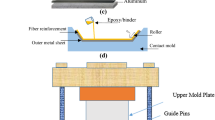

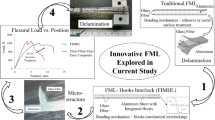

Fiber-metal laminates (FMLs) such as Kevlar reinforced aluminum laminate (ARALL), Carbon reinforced aluminum laminate (CARALL), and Glass reinforced aluminum laminate (GLARE) offer great potential for weight reduction applications in automobile and aerospace construction. In order to investigate the feasibility for utilizing such materials in the form of laminates, sheet hydroforming technology are studied under the condition of uniform blank holder force for three-layered aluminum and aluminum-composite laminates using orthogonal carbon and Kevlar as well as glass fiber in the middle. The experimental results validate the finite element results and they exhibited that the forming limit of glass fiber in the middle is the highest among the studied materials, while carbon fiber material performs the worst. Furthermore, the crack modes are different for the three kinds of fiber materials investigated in the research. This study provides fundamental guidance for the selection of multi-layer sheet materials in the future manufacturing field.

Similar content being viewed by others

References

Botelho, E.C.: A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater. Res. 9, 247–256 (2006)

Vogelesang, L.B., Vlot, A.: Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 103(1), 1–5 (2000)

Vermeeren, A.J.R.: A historical overview of the development of Fiber-metal laminate. J Composite Material. 10, 189–205 (2003)

Asundi, A., Choi, A.Y.N.: Fiber metal laminates: an advanced material for future aircraft. J Mater Process Tech. 63, 384–394 (1997)

Reyes, G., Kang, H.: Mechanical behavior of lightweight thermoplastic fiber–metal laminates. J Mater Process Tech. 186, 284–290 (2007)

Olga, S., Adele, C., Heinz, P.: Metal–polymer–metal sandwiches with local metal reinforcements: a study on formability by deep drawing and bending. Compos. Struct. 94, 1–7 (2011)

Vogelesang, L.B., Gunnink, J.W.: ARALL: a materials challenge for the next generation of aircraft. J. Mater. Design. 7, 287–300 (1986)

Wu, G., Yang, J.-M.: The Mechanical Behavior of GLARE Laminates for Aircraft Structures. J Fail Struct Mater. 7, 72–79 (2005)

Park, S.Y., Choi, W.J., Choi, H.S.: A comparative study on the properties of GLARE laminates cured by autoclave and autoclave consolidation followed by oven postcuring. Int. J. Adv. Manuf. Technol. 49, 605–613 (2010)

Yanagimoto, J., Ikeuchi, K.: Sheet forming process of carbon fiber reinforced plastics for lightweight parts. J CIRP Ann-Manuf Technol. 61(1), 247–250 (2012)

Dı́az, J., Rubio, L.: Developments to manufacture structural aeronautical parts in carbon fibre reinforced thermoplastic materials. J. Mater. Process. Technol. 144(0), 342–346 (2003)

Hou, M., Ye, L., Mai, Y.W.: Manufacturing process and mechanical properties of thermoplastic composite components. J. Mater. Process. Technol. 63(1–3), 334–338 (1997)

Rajkumar, G.R., Krishna, M.: Investigation of tensile and bending behavior of aluminum based hybrid fiber metal laminates. Procedia Mater Sci. 5, 60–68 (2014)

Aukush, P., Sanan, H.: Experimental and numerical investigation on the uniaxial tensile response and failure of fiber metal laminates. Compos Part B. 125(15), 259–274 (2017)

Correia, J.P., Ahzi, S.: Electromagnetic sheet bulging: analysis of process parameters by FE simulations. Key Eng. Mater. 554, 741–748 (2013)

Wang, Z.J., Li, Y.: Evaluation of forming limit in viscous pressure forming of automobile aluminum alloy 6k21-T4 sheet. Trans Nonferrous Met Soc China. 17, 1169–1174 (2007)

He, Z.B., Yuan, S.J.: Analytical model for tube hydro-bulging tests, part II:linear model for pole thickness and its application. Int J Mech Sci. 87, 307–315 (2014)

Wang, Y., Lang, L., Zafar, R.: Investigation into the overlapping sheet hydraulic bulge and its formability. J. Braz. Soc. Mech. Sci. Eng. 38(6), 1635–1645 (2016)

Acknowledgments

The authors greatly acknowledge the financial support from National Science Foundation of China with Grant No.51675029.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, S., Lang, L., Guan, S. et al. Investigation into Composites Property Effect on the Forming Limits of Multi-Layer Hybrid Sheets Using Hydroforming Technology. Appl Compos Mater 26, 205–217 (2019). https://doi.org/10.1007/s10443-018-9689-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-018-9689-x