Abstract

In the present work, the response of closed-cell aluminum foams under low-velocity impact has been studied numerically and experimentally. Computerized tomography is employed to access three-dimensional (3D) microstructure of the closed-cell aluminum foam. Effective parameters including foam density and the velocity of impactor on foam dynamic behavior are investigated. In order to show the validity and accuracy of results, some static experiments and low-velocity impact tests have been conducted. Results indicate a remarkable agreement between the simulation and experimental data. Moreover, the results show that by increasing the density of foam samples, the highest difference between numerical and experimental results for peak stress and absorbed energy are 35.9% and 6.9%, respectively, which is related to the highest density. For impact velocities ranging from 3.1 to 4.2 m/s, the maximum discrepancy in peak stress and absorbed energy occur at an impact velocity of 3.1 m/s in which corresponding errors are 33.3% and 6.6%, respectively. For the impact velocity of 40 m/s, the highest increase in peak stress and absorbed energy are 667.9% and 370.3% associated with the density of 0.5 and 0.3 g/cm3, respectively.

Similar content being viewed by others

References

Peroni, M., Solomos, G., Pizzinato, V.: Impact behaviour testing of aluminium foam. Int. J. Impact Eng. 53, 74–83 (2013)

Banhart, J.: Manufacture, characterisation, and application of cellular materials and metal foams. Prog. Mater. Sci. 46, 559–632 (2001)

Ashby, F., Evans, A., Fleck, N.A., et al.: Metal Foams: A Design Guide. Elsevier, Amsterdam (2000)

Evans, A.G., Hutchinson, J.W., Fleck, N.A., et al.: The topological design of multifunctional cellular metals. Prog. Mater. Sci. 46, 309–327 (2001)

Singh, R., Lee, P.D., Lindley, T.C., et al.: Characterization of the deformation behavior of intermediate porosity interconnected Ti foams using micro-computed tomography and direct finite element modeling. Acta Biomater. 6, 2342–2351 (2010)

Dannemann, K.A., Lankford, J.: High strain rate compression of closed-cell aluminium foams. Mater. Sci. Eng. A 293, 157–164 (2000)

Liu, Y., Gong, W., Zhang, X.: Numerical investigation of influences of porous density and strain-rate effect on dynamical responses of aluminum foam. Comput. Mater. Sci. 91, 223–230 (2014)

Montanini, R.: Measurement of strain rate sensitivity of aluminium foams for energy dissipation. Int. J. Mech. Sci. 47, 26–42 (2005)

Fang, Q., Zhang, J., Zhang, Y., et al.: Mesoscopic investigation of closed-cell aluminum foams on energy absorption capability under impact. Compos. Struct. 124, 409–420 (2015)

Li, B., Zhao, G., Lu, T.: Low strain rate compressive behavior of high porosity closed-cell aluminum foams. Sci. China Technol. Sci. 55, 451–463 (2012)

Yun, N., Shin, D., Ji, S., et al.: Experiments on blast protective systems using aluminum foam panels. KSCE J. Civ. Eng. 18, 2153–2161 (2014)

Wang, P., Xu, S., Li, Z., et al.: Experimental investigation on the strain-rate effect and inertia effect of closed-cell aluminum foam subjected to dynamic loading. Mater. Sci. Eng. A 620, 253–261 (2015)

Toda, H., Ohgaki, T., Uesugi, K., et al.: In situ observation of fracture of aluminium foam using synchrotron X-ray microtomography. Key Eng. Mater. 297, 1189–1195 (2005)

Toda, H., Takata, M., Ohgaki, T., et al.: 3-D image-based mechanical simulation of aluminium foams: effects of internal microstructure. Adv. Eng. Mater. 8, 459–467 (2006)

Toda, H., Sinclair, I., Buffière, J., et al.: A 3D measurement procedure for internal local crack driving forces via synchrotron X-ray microtomography. Acta Mater. 52, 1305–1317 (2004)

Sassov, A., Cornelis, E., Dyck, D.: Non-destructive 3D investigation of metal foam microstructure. Materialwissenschaft Werkst. 31, 571–573 (2000)

Ohgaki, T., Toda, H., Kobayashi, M., et al.: In-situ high resolution x-ray CT observation of compressive and damage behavior of aluminum foams by local tomography technique. Adv. Eng. Mater. 8, 473–475 (2006)

Elmoutaouakkil, A., Salvo, L., Maire, E., et al.: 2D and 3D characterization of metal foams using X-ray tomography. Adv. Eng. Mater. 4, 803–807 (2002)

Veyhl, C., Belova, I.V., Murch, G.E., et al.: Finite element analysis of the mechanical properties of cellular aluminium based on micro-computed tomography. Mater. Sci. Eng. A 528, 4550–4555 (2011)

Miedzinska, D., Niezgoda, T., Gieleta, R.: Numerical and experimental aluminum foam microstructure testing with the use of computed tomography. Comput. Mater. Sci. 64, 90–95 (2012)

Ramirez, J.F., Cardona, M., Velez, J.A., et al.: Numerical modeling and simulation of uniaxial compression of aluminum foams using FEM and 3D-CT images. Proc. Mater. Sci. 4, 227–231 (2014)

Saadatfar, M., Mukherjee, M., Madadi, M., et al.: Structure and deformation correlation of closed-cell aluminium foam subject to uniaxial compression. Acta Mater. 60, 3604–3615 (2012)

Kader, M.A., Islam, M.A., Hazell, P.J., et al.: Modelling and characterization of cell collapse in aluminium foams during dynamic loading. Int. J. Impact Eng. 96, 78–88 (2016)

Islam, M.A., Brown, A.D., Hazell, P.J., et al.: Mechanical response and dynamic deformation mechanisms of closed-cell aluminium alloy foams under dynamic loading. Int. J. Impact Eng. 114, 111–122 (2018)

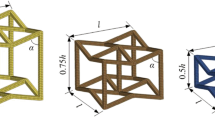

Hedayati, R., Sadighi, M., Mohammadi-Aghdam, M., et al.: Mechanical properties of regular porous biomaterials made from truncated cube repeating unit cells: analytical solutions and computational models. Mater. Sci. Eng. C 60, 163–183 (2016)

Hedayati, R., Sadighi, M., Mohammadi-Aghdam, M., et al.: Mechanical behavior of additively manufactured porous biomaterials made from truncated cuboctahedron unit cells. Int. J. Mech. Sci. 106, 19–38 (2016)

Su, X.Y., Yu, T.X., Reid, S.R.: Inertia-sensitive impact energy absorbing structures, part II: effect of strain rate. Int. J. Impact Eng. 16, 673–689 (1995)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Talebi, S., Sadighi, M. & Aghdam, M.M. Numerical and experimental analysis of the closed-cell aluminium foam under low velocity impact using computerized tomography technique. Acta Mech. Sin. 35, 144–155 (2019). https://doi.org/10.1007/s10409-018-0795-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-018-0795-7