Abstract

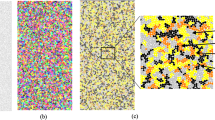

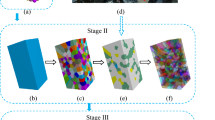

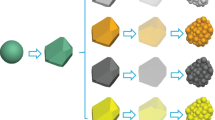

In this paper, a cluster model in particle flow code was used to simulate granite specimens after heat treatment under uniaxial compression. The results demonstrated that micro-cracks are randomly distributed in the specimen when the temperature is below 300 \({^{\circ }}\)C, and have partial coalescence when the temperature is up to 450 \({^{\circ }}\)C, then form macro-cracks when the temperature is above 600 \({^{\circ }}\)C. There is more inter-granular cracking than intra-granular cracking, and their ratio increases with increasing temperature. The micro-cracks are almost constant when the temperature decreases from 900 \({^{\circ }}\)C to room temperature, except for quartz \(\alpha \)–\(\beta \) phase transition temperature (573 \({^{\circ }}\)C). The fracture evolution process is obviously affected by these cracks, especially at 600–900 \({^{\circ }}\)C. Elevated temperature leads to easily developed displacement between the grains, and the capacity to store strain energy becomes weaker, corresponding to the plasticity of granite after heat treatment.

Similar content being viewed by others

References

Shao, S., Wasantha, P.L.P., Ranjith, P.G., et al.: Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 70, 381–387 (2014)

Baisch, S., Weidler, R., Vörös, R., et al.: Induced seismicity during the stimulation of a geothermal HFR reservoir in the Cooper Basin. Aust. Bull. Seismol. Soc. Am. 96, 2242–2256 (2006)

Yang, S.Q., Ranjith, P.G., Jing, H.W., et al.: An experimental investigation on thermal damage and failure mechanics behavior of granite after exposure to different high temperature treatments. Geothermics 65, 180–197 (2017)

Rutqvist, J.: The geomechanics of CO\(_2\) storage in deep sedimentary formations. Off. Sci. Tech. Inf. Tech. Rep. 30, 525–551 (2011)

Homand-Etienne, F., Houpert, R.: Thermally induced microcracking in granites: characterization and analysis. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 26, 125–134 (1989)

David, C., Menéndez, B., Darot, M.: Influence of stress-induced and thermal cracking on physical properties and microstructure of La Peyratte granite. Int. J. Rock Mech. Min. Sci. 36, 433–448 (1999)

Menéndez, B., David, C., Darot, M.A.: Study of the crack network in thermally and mechanicsly cracked granite samples using confocal scanning laser microscopy. Phys. Chem. Earth Part A Solid Earth Geod. 24, 627–632 (1999)

Chaki, S., Takarli, M., Agbodjan, W.P.: Influence of thermal damage on physical properties of a granite rock: porosity, permeability and ultrasonic wave evolutions. Constr. Build. Mater. 22, 1456–1461 (2008)

Glover, P.W.J., Baud, P., Darot, M., et al.: \(\alpha \)/\(\beta \) phase transition in quartz monitored using acoustic emissions. Geophys. J. Int. 120, 775–782 (1995)

Zhao, Y.S., Meng, Q.R., Kang, T.L., et al.: Micro-CT experimental technology and micro-investigation on thermal fracturing characteristics of granite. Chin. J. Rock Mech. Eng. 27, 28–34 (2008)

Sun, Q., Zhang, Z.Z., Xue, L., et al.: Physico-mechanics properties variation of rock with phase transformation under high temperature. Chin. J. Rock Mech. Eng. 32, 935–942 (2013). (in Chinese)

Shao, S., Ranjith, P.G., Wasantha, P.L.P., et al.: Experimental and numerical studies on the mechanics behaviour of Australian Strathbogie granite at high temperatures: an application to geothermal energy. Geothermics 54, 96–108 (2015)

Kumari, W.G.P., Ranjith, P.G., Perera, M.S.A., et al.: Mechanics behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: an application to geothermal energy extraction. Geothermics 65, 44–59 (2017)

Ghassemi, A.: A review of some rock mechanics issues in geothermal reservoir development. Geotech. Geol. Eng. 30, 647–664 (2012)

Yu, Q.L., Ranjith, P.G., Liu, H.Y., et al.: A microstructure-based damage model for thermal cracking analysis and application in granite at elevated temperatures. Rock Mech. Rock Eng. 48, 2263–2282 (2015)

Zhao, Z.: Thermal influence on mechanics properties of granite: a microcracking perspective. Rock Mech. Rock Eng. 49, 747–762 (2016)

Yang, S.Q., Tian, W.L., Ranjith, P.G.: Failure mechanical behavior of Australian strathbogie granite at high temperatures: insights from particle flow modeling. Energies 10, 756 (2017)

Itasca Consulting Group, Inc.: PFC2D, v. 3.10. Minneapolis, MN (2003)

Jensen, R.P., Bosscher, P.J., Plesha, M.E., et al.: DEM simulation of granular media–structure interface: effects of surface roughness and particle shape. Int. J. Num. Anal. Meth. Geomech. 23, 531–47 (1999)

Thomas, P.A., Bray, J.D.: Capturing nonspherical shape of granular media with disk clusters. J. Geotech. Geoenviron. Eng. 125, 169–78 (1999)

Cho, N., Martin, C.D., Sego, D.C.: A clumped particle model for rock. Int. J. Rock Mech. Min. Sci. 44, 997–1010 (2007)

Fei, Y.: Thermal expansion. In: Mineral Physics and Crystallography: A Handbook of Physical Constants, 29–44. AGU, Wasington, DC (1995)

Carpenter, M.A., Salje, E.K.H., Graeme-Barber, A.: Spontaneous Strain as a Determinant of Thermodynamic Properties for Phase Transitions in Minerals. Eur. J. Miner. 10, 621–691 (1998)

Zhang, X.P., Wong, N.Y.: Cracking processes in rock-like material containing a single flaw under uniaxial compression: a numerical study based on parallel bonded-particle model approach. Rock Mech. Rock Eng. 45, 711–737 (2012)

Huang, Y.H., Yang, S.Q., Tian, W.L., et al.: Physical and mechanical behavior of granite containing pre-existing holes after high temperature treatment. Arch. Civil Mech. Eng. 17, 912–925 (2017)

Acknowledgements

The project was supported by the National Natural Science Foundation of Jiangsu Province of China for Distinguished Young Scholars (Grant BK20150005) and the Fundamental Research Funds for the Central Universities (China University of Mining and Technology) (Grant 2014XT03). We also would like to express our sincere gratitude to the editor and two reviewers for their valuable comments, which have greatly improved this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, WL., Yang, SQ. & Huang, YH. Macro and micro mechanics behavior of granite after heat treatment by cluster model in particle flow code. Acta Mech. Sin. 34, 175–186 (2018). https://doi.org/10.1007/s10409-017-0714-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-017-0714-3