Abstract

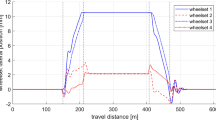

This paper proposes a systematic method, integrating the uniform design (UD) of experiments and quantum-behaved particle swarm optimization (QPSO), to solve the problem of a robust design for a railway vehicle suspension system. Based on the new nonlinear creep model derived from combining Hertz contact theory, Kalker’s linear theory and a heuristic nonlinear creep model, the modeling and dynamic analysis of a 24 degree-of-freedom railway vehicle system were investigated. The Lyapunov indirect method was used to examine the effects of suspension parameters, wheel conicities and wheel rolling radii on critical hunting speeds. Generally, the critical hunting speeds of a vehicle system resulting from worn wheels with different wheel rolling radii are lower than those of a vehicle system having original wheels without different wheel rolling radii. Because of worn wheels, the critical hunting speed of a running railway vehicle substantially declines over the long term. For safety reasons, it is necessary to design the suspension system parameters to increase the robustness of the system and decrease the sensitive of wheel noises. By applying UD and QPSO, the nominal-the-best signal-to-noise ratio of the system was increased from −48.17 to −34.05 dB. The rate of improvement was 29.31%. This study has demonstrated that the integration of UD and QPSO can successfully reveal the optimal solution of suspension parameters for solving the robust design problem of a railway vehicle suspension system.

Similar content being viewed by others

Abbreviations

- \(\bar{{a}}_{ij} , \bar{{b}}_{ij} \) :

-

Semi axis lengths of the wheel/rail elliptical contact region

- \(C_{11,ij} \) :

-

Lateral creepage for new nonlinear creep model

- \(C_{22,ij} \) :

-

Lateral/spin creepage for new nonlinear creep model

- \(C_{23,ij} \) :

-

Spin creepage for new nonlinear creep model

- \(C_{33,ij} \) :

-

Longitudinal creepage for new nonlinear creep model

- \(f_{11,ij} \) :

-

Lateral creep coefficient for new nonlinear creep model

- \(f_{12,ij} \) :

-

Lateral/spin creep coefficient for new nonlinear creep model

- \(f_{22,ij} \) :

-

Spin creep coefficient for new nonlinear creep model

- \(f_{33,ij} \) :

-

Longitudinal creep coefficient for new nonlinear creep model

- \(F_{kxij} , F_{kyij} \) :

-

Linear creep force on wheels in lateral and vertical directions, respectively

- \(F_{kxij}^*, F_{kyij}^*\) :

-

Linear creep force on wheels obtained from Kalker linear theory in lateral and vertical directions, respectively

- \(F_{kxij}^n , F_{kyij}^n \) :

-

Nonlinear creep force on wheels in lateral and vertical directions, respectively

- \(F_{syc} , F_{szc} \) :

-

Suspension force on car body in lateral and vertical directions, respectively

- \(F_{syij} , F_{szij} \) :

-

Suspension force on each wheelset in lateral and vertical directions, respectively

- \(F_{syti} , F_{szti} \) :

-

Suspension forces on each bogie frame in lateral and vertical directions, respectively

- G :

-

Combined shear modulus of rigidity of wheel and rail materials

- \(G\left( t \right) \) :

-

Global best position in iteration t for quantum-behaved particle swarm optimization (QPSO)

- \(M_{exij} \) :

-

External moment on each wheelset in longitudinal direction

- \(M_{kxij} , M_{kzij} \) :

-

Linear creep moment on each wheel in longitudinal and vertical directions, respectively

- \(M_{kzij}^n \) :

-

Nonlinear creep moment on each wheel in vertical direction

- \(M_{sxc} , M_{szc} \) :

-

Suspension moment on car body in longitudinal and vertical directions, respectively

- \(M_{sxij} , M_{szij} \) :

-

Suspension moment on each wheelset in longitudinal and vertical directions, respectively

- \(M_{sxti} , M_{szti} \) :

-

Suspension moment on each bogie frame in longitudinal and vertical directions, respectively

- \(N_{ij}^*\) :

-

Normal force in equilibrium state on each wheelset

- \(P_\ell \left( t \right) \) :

-

The best position of particle \(\ell \) for QPSO

- \(r_0 \) :

-

Wheel nominal rolling radius

- \(r_{i1} \) :

-

Wheel rolling radius of the front wheel of the ith bogie frame (\(i=1, 2\))

- \(r_{i2} \) :

-

Wheel rolling radius of the rear wheel of the ith bogie frame (\(i=1, 2\))

- \(\Delta r_{i1} \) :

-

Noise of \(r_{i1} (i=1, 2)\)

- \(\Delta r_{i2} \) :

-

Noise of \(r_{i2} (i=1, 2)\)

- \(r_{Lij} , r_{Rij} \) :

-

Rolling radius at the contact point for the left and right wheel

- t :

-

Time

- V :

-

Forward speed of the vehicle

- \(W_{\mathrm{ext}} \) :

-

External weight acting on each wheelset

- \(X_\ell \left( t \right) \) :

-

Position of particle \(\ell \) in iteration t for QPSO

- \(\alpha _{ij}^*\) :

-

Saturation constant of front and rear wheelsets for new nonlinear creep model

- \(\beta _{ij}^*\) :

-

Nonlinearity constant of front and rear wheelsets for new nonlinear creep model

- \(\beta _{kij} \) :

-

Nonlinearity constant of left and right wheels for new nonlinear creep model

- \(\lambda \) :

-

Wheel conicity

- \(\Delta \lambda \) :

-

Noise of \(\lambda \)

- \(\zeta \) :

-

Contraction-expansion coefficient

References

Zeng, X.H., Wu, H., Lai, J., et al.: Hunting stability of high-speed railway vehicles on a curved track considering the effects of steady aerodynamic loads. J. Vib. Control 22, 4159–4175 (2016)

Zeng, X.H., Wu, H., Lai, J., et al.: Influences of aerodynamic loads on hunting stability of high-speed railway vehicles and parameter studies. Acta Mech. Sin. 30, 889–900 (2014)

Molatefi, H., Hecht, M., Kadivar, M.H.: Critical speed and limit cycles in the empty y25-freight wagon. Proc. Inst. Mech. Eng. Part F: J. Rail Rapid Transit 220, 347–359 (2006)

Wang, K.Y., Liu, P.F.: Lateral stability analysis of heavy-haul vehicle on curved track based on wheel/rail coupled dynamics. J. Transp. Technol. 2, 150–157 (2012)

Kim, P., Seok, J.: Bifurcation analysis on the hunting behavior of a dual-bogie railway vehicle using the method of multiple scales. J. Sound Vib. 329, 4017–4039 (2010)

Karim, H., Ali, A., Rasheed, A.K.: Investigation to improve hunting stability of railway carriage using semi-active longitudinal primary stiffness suspension. J. Mech. Eng. Res. 2, 97–105 (2010)

Michal, M., Michael, H.: Effects of speed, load and damping on the dynamic response of railway bridges and vehicles. Comput. Struct. 86, 556–572 (2008)

Ranjbar, M., Ghazavi, M.R.: Lateral stability analysis of high-speed railway vehicle on curve. In: Proceeding of International Conference on Advances in Robotic, Mechanical Engineering and Design, Chandigarh, 11–14 (2012)

Gao, X.J., Li, Y.H., Yue, Y., et al.: Symmetric/asymmetric bifurcation behaviours of a bogie system. J. Sound Vib. 332, 936–951 (2013)

Molatefi, H., Hecht, M., Kadivar, M.H.: Effect of suspension system in the lateral stability of railway freight trucks. Proc. Inst. Mech. Eng. Part F: J. Rail Rapid Transit 221, 399–407 (2007)

Piotrowski, J., Kik, W.: A simplified model of wheel/rail contact mechanics for non-hertzian problems and its application in rail vehicle dynamic simulations. Veh. Syst. Dyn. 46, 27–48 (2008)

Pombo, J., Ambrósio, J., Silva, M.: A new wheel-rail contact model for railway dynamics. Veh. Syst. Dyn. 45, 165–189 (2007)

Polach, O.: On non-linear methods of bogie stability assessment using computer simulations. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 220, 13–27 (2006)

Kovalev, R., Yazykov, V.N., Mikhalchenko, G.S., et al.: Railway vehicle dynamics: some aspects of wheel-rail contact modeling and optimization of running gears. Mech. Based Des. Struct. Mach. 31, 315–334 (2003)

Shen, G., Zhong, X.: A design method for wheel profiles according to the rolling radius difference function. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 225, 457–462 (2011)

Sun, S., Li, L., Zhou, J., et al.: Influence of wheel diameter difference on safety and stationarity of vehicles crawling over the curved bridge. Appl. Mech. Mater. 209–211, 2117–2120 (2012)

He, Y., McPhee, J.: Optimization of the lateral stability of rail vehicles. Veh. Syst. Dyn. 38, 361–390 (2002)

He, Y., McPhee, J.: Optimization of curving performance of rail vehicles. Veh. Syst. Dyn. 43, 859–923 (2005)

Sayyaadi, H., Shokouhi, N.: New dynamics model for rail vehicles and optimizing air suspension parameters using GA. Sci. Iran. 16, 496–512 (2009)

Wu, Q., Cole, C., McSweeney, T.: Applications of particle swarm optimization in the railway domain. Int. J. Rail Transp. 4, 167–190 (2016)

Cheng, Y.C., Lee, C.K.: Robust design of suspension parameters for high speed railway vehicle based on uniform design and kriging interpolation. Int. J. Adv. Mechatron. Syst. 3, 268–278 (2011)

Lee, C.K., Cheng, Y.C.: Application of uniform design and quantum-behaved particle swarm optimization in solving the sensitivity problem a railway vehicle system. Procedia Eng. 79, 4227–4436 (2014)

Nejlaoui, M., Houidi, A., Affi, Z., et al.: Multiobjective robust design optimization of rail vehicle moving in short radius curved tracks based on the safety and comfort criteria. Simul. Model. Pract. Theory 30, 21–34 (2013)

Lee, K.K., Park, C.K., Han, S.H.: Robust design of railway vehicle suspension using a process capability index. J. Mech. Sci. Technol. 24, 215–218 (2010)

Cheng, Y.C.: Hunting stability analysis of a railway vehicle system using a novel non-linear creep model. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 226, 612–629 (2012)

Vidyasager, M.: Nonlinear Systems Analysis. Prentice-Hall Press, Hyderabad (1978)

Garg, V.K., Dukkipati, R.V.: Dynamics of Railway Vehicle Systems. Academic Press, Orlanda (1984)

Adachi, M., Terumichi, Y., Suda, Y., et al.: Analysis on wheel load variation in coupled motion between wheel and track. Trans. Jpn. Soc. Mech. Eng. Ser. C 73, 748–755 (2007)

Ahmed, A.K.W., Sankar, S.: Lateral stability behavior of railway freight car system with elasto-damper coupled wheelset: part 2—truck model. Trans. ASME J. Mech. Transm. Autom. Des. 109, 500–507 (1987)

John, A.R.: Mathematical Statistics and Data Analysis, 2nd edn. Duxbury Press, Belmont (1994)

Fang, K.T., Wang, Y.: Number-Theoretic Methods in Statistics. Chapman & Hall Press, London (1994)

Wang, J.M., Lan, S., Li, W.K.: Numerical simulation and process optimization of an aluminum holding furnace based on response surface methodology and uniform design. Energy 72, 521–535 (2014)

Li, D.J., Song, J.F., Xu, A.Q., et al.: Optimization of the ultrasound-assisted synthesis of lutein disuccinate using uniform design. Ultrason. Sonochem. 21, 98–103 (2014)

Dai, C., Wang, Y.: A new decomposition based evolutionary algorithm with uniform designs for many-objective optimization. Appl. Soft Comput. J. 30, 238–248 (2015)

Voratas, K.: Comparison of three evolutionary algorithms: GA, PSO, and DE. Ind. Eng. Manag. Syst. 11, 215–223 (2012)

Sun, J., Feng, B., Xu, W.: Particle swarm optimization with particles having quantum behavior. IEEE Congr. Evol. Comput. 1, 325–331 (2004)

Sun, J., Wu, X., Palade, V., et al.: Convergence analysis and improvements of quantum-behaved particle swarm optimization. Inf. Sci. 193, 81–103 (2012)

Clerc, M., Kennedy, J.: The particle swarm: explosion, stability, and convergence in a multi-dimensional complex space. IEEE Trans. Evol. Comput. 6, 58–73 (2002)

Sun, J., Xu, W., Feng, B.: A global search strategy of quantum-behaved particle swarm optimization. IEEE Conf. Cybern. Intell. Syst. 1, 111–116 (2004)

Acknowledgements

The authors gratefully acknowledge the Ministry of Science and Technology of Taiwan (Grants MOST 104-2221-E-327-019, MOST 105-2221-E-327-014) for financial support of this study.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: System parameters (Refs. [10, 28, 29])

Parameters | Value |

|---|---|

Wheelset mass | \(m_w =1117.9\) kg |

Bogie frame mass | \(m_t =350.26\) kg |

Car body mass | \(m_c =8041.3\) kg |

Roll moment of the inertia of the wheelset | \(I_{wx} =608.1 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Spin moment of the inertia of the wheelset | \(I_{wy} =72 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Yaw moment of the inertia of the wheelset | \(I_{wz} =608.1 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Roll moment of the inertia of the bogie frame | \(I_{tx} =300 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Yaw moment of the inertia of the bogie frame | \(I_{tz} =105.2 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Roll moment of the inertia of the car body | \(I_{cx} =14270 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Yaw moment of the inertia of the car body | \(I_{cz} =123760.5 \,\,\hbox {kg}\cdot \hbox {m}^{2}\) |

Wheel radius | \(r_0 =0.43\) m |

Half of track gauge | \(a=0.7175\) m |

Wheel conicity | \(\lambda =0.05\) |

Half of primary longitudinal spring arm | \(b_1 =1.0\) m |

Half of primary longitudinal damping arm | \(b_1 =1.0\) m |

Half of primary vertical spring arm | \(b_1 =1.0\) m |

Half of primary vertical damping arm | \(b_1 =1.0\) m |

Half of secondary longitudinal spring arm | \(b_2 =1.18\) m |

Half of secondary longitudinal damping arm | \(b_3 =1.4\) m |

Half of secondary vertical spring arm | \(b_2 =1.18\) m |

Half of secondary vertical damping arm | \(b_3 =1.4\) m |

Half of primary lateral spring arm | \(L_1 =1.5\) m |

Half of primary lateral damping arm | \(L_2 =1.5\) m |

Longitudinal distance from wheelset center of gravity to car body | \(L_c =4.2\) m |

Height of external weight above center of gravity of wheelset | \(h=1.4\) m |

Vertical distance from wheelset center of gravity to car body | \(h_C =1.67\) m |

Vertical distance from wheelset center of gravity to secondary suspension | \(h_T =0.47\) m |

Longitudinal stiffness of primary suspension | \(K_{px} = 9\times 10^{5}\) N/m |

Lateral stiffness of primary suspension | \(K_{py} =3.9\times 10^{5}\) N/m |

Vertical stiffness of primary suspension | \(K_{pz} =6\times 10^{5}\) N/m |

Vertical damping of primary suspension | \(C_{pz} =4\times 10^{4} \,\,\hbox {N}\cdot \hbox {s}\)/m |

Longitudinal stiffness of secondary suspension | \(K_{sx} =3.5\times 10^{4}\) N/m |

Lateral stiffness of secondary suspension | \(K_{sy} =3.5\times 10^{4}\) N/m |

Vertical stiffness of secondary suspension | \(K_{sz} =3.5\times 10^{5}\) N/m |

Longitudinal damping of secondary suspension | \(C_{sx} =3.2\times 10^{4} \,\,\hbox {N}\cdot \hbox {s}\)/m |

Lateral damping of secondary suspension | \(C_{sy} =1\times 10^{4} \,\,\hbox {N}\cdot \hbox {s}\)/m |

Vertical damping of secondary suspension | \(C_{sz} =4\times 10^{4} \,\,\hbox {N}\cdot \hbox {s}\)/m |

Radius of curved tracks | \(R=1500\) m |

Superelevation angle of curved track | \(\phi _{se} =0.0524\) rad |

External load | \(W_\mathrm{ext} =5.6\times 10^{4}\) N |

Coefficient of friction | \(f=0.2\) |

Normal force acting on wheelset in equilibrium state | \(N={W_\mathrm{ext} }/2\) N |

Young’s modulus of wheels | \(E_w =2.058\times 10^{11}\) Pa |

Young’s modulus of rails | \(E_R =2.058\times 10^{11}\) Pa |

Poisson’s ratio of wheels | \(\sigma _R =0.3\) |

Poisson’s ratio of rails | \(\sigma _w =0.3\) |

Principal rolling radius of the wheel | \(R_1 =r_0 =0.43\) m |

Principal transverse radius of curvature of the wheel profile at the point of contact | \(R^{\prime }_1 =\infty \) |

Principal rolling radius of the rail at the point of contact | \(R_2 =\infty \) |

Principal transverse radius of curvature of the rail profile at the point of contact | \(R^{\prime }_2 =0.6\) m |

Appendix B

Normal forces:

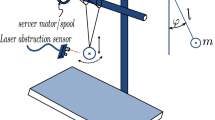

Assuming the equilibrium speed motion of wheelsets on the circular curved tracks (Fig. 2), the vertical components of normal force for each wheelset are calculated and expressed as

Speed-dependent and linear creep forces and creep moments:

Considering the various wheel conicities \(\lambda _{ij} \) and wheel rolling radii \(r_{ij} \) at wheel/rail contact surfaces after wheel turning, the linear creep forces and moments directly calculated via Kalker’s linear theory are calculated and expressed as

where \(r_{Lij} =r_{ij} +\lambda _{ij} y_{wij} \), \(r_{Rij} =r_{ij} -\lambda _{ij} y_{wij} \), \(\delta _{Lij} =\delta _{Rij} =\lambda _{ij} \), \(\delta _{Lij} =\delta _{Rij} =\lambda _{ij} \).

Suspension forces and moments:

Wheelsets

Bogie frame

Car body

Rights and permissions

About this article

Cite this article

Cheng, YC., Lee, CK. Integration of uniform design and quantum-behaved particle swarm optimization to the robust design for a railway vehicle suspension system under different wheel conicities and wheel rolling radii. Acta Mech. Sin. 33, 963–980 (2017). https://doi.org/10.1007/s10409-017-0658-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-017-0658-7