Abstract

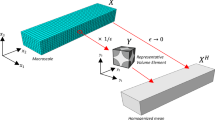

Asymptotic homogenization (AH) is a general method for predicting the effective coefficient of thermal expansion (CTE) of periodic composites. It has a rigorous mathematical foundation and can give an accurate solution if the macrostructure is large enough to comprise an infinite number of unit cells. In this paper, a novel implementation algorithm of asymptotic homogenization (NIAH) is developed to calculate the effective CTE of periodic composite materials. Compared with the previous implementation of AH, there are two obvious advantages. One is its implementation as simple as representative volume element (RVE). The new algorithm can be executed easily using commercial finite element analysis (FEA) software as a black box. The detailed process of the new implementation of AH has been provided. The other is that NIAH can simultaneously use more than one element type to discretize a unit cell, which can save much computational cost in predicting the CTE of a complex structure. Several examples are carried out to demonstrate the effectiveness of the new implementation. This work is expected to greatly promote the widespread use of AH in predicting the CTE of periodic composite materials.

Similar content being viewed by others

References

Sigmund, O., Torquato, S.: Design of materials with extreme thermal expansion using a three-phase topology optimization method. J. Mech. Phys. Solids. 45, 1037–1067 (1997)

Steeves, C.A., Evans, A.G.: Optimization of thermal protection systems utilizing sandwich structures with low coefficient of thermal expansion lattice hot faces. J. Am. Ceram. Soc. 94, S55–S61 (2011)

Zhang, X.X., Xiao, B.L., Andra, H., et al.: Multi-scale modeling of the macroscopic, elastic mismatch and thermal misfit stresses in metal matrix composites. Compos. Struct. 125, 176–187 (2015)

Palumbo, N.M.A., Smith, C.W., Miller, W., et al.: Near-zero thermal expansivity 2-D lattice structures: performance in terms of mass and mechanical properties. Acta Mater. 59, 2392–2403 (2011)

Ozaki, T., Naito, K., Mikami, I., et al.: High precision composite pipes for SOLAR-B optical structures. Acta Astronaut. 48, 321–329 (2001)

Schapery, R.A.: Thermal expansion coefficients of composite materials based on energy principles. J. Compos. Mater. 2, 380–404 (1968)

Chamis, C.C., Sendeckyj, G.P.: Critique on theories predicting thermoelastic properties of fibrous composites. J. Compos. Mater. 2, 332–358 (1968)

Walter, B., Rosen, Z.H.: Effective thermal expansion coefficients and specific heats of composite materials. Int. J. Eng. Sci. 8, 157–173 (1970)

Hashin, Z.: Analysis of composite materials, a survey. J. Appl. Mech. 50, 481–505 (1983)

Bowles, D.E., Tompkins, S.S.: Prediction of coefficients of thermal expansion for unidirectional composites. J. Compos. Mater. 23, 370–388 (1989)

Shen, Y.L.: Thermal expansion of metal-ceramic composites: a three-dimensional analysis. Mater. Sci. Eng. A 252, 269–275 (1998)

Islam, M.D.R., Sjolind, S.G., Pramila, A.: Finite element analysis of linear thermal expansion coefficients of unidirectional cracked composites. J. Compos. Mater. 35, 1762–1776 (2001)

Karadeniz, Z.H., Kumlutas, D.: A numerical study on the coefficients of thermal expansion of fiber reinforced composite materials. Compos. Struct. 78, 1–10 (2007)

Hu, C.X., Zhang, S.Y., Song, Y.S.: Numerical simulation on thermal expansion coefficient of 3D braided C/C composites. Rare Met. 33, 99–106 (2004)

Ai, S.G., Fu, H.L., He, R.J., et al.: Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature. Mater. Design 82, 181–188 (2015)

Abueidda, D.W., Dalaqa, A.S., Al-Ru, R.K.A., et al.: Micromechanical finite element predictions of a reduced coefficient of thermal expansion for 3D periodic architectured interpenetrating phase composites. Compos. Struct. 133, 85–97 (2015)

Mei, C.C., Vernescu, B.: Homogenization methods for multiscale mechanics. World Scientific, New York (2010)

Kalamkarov, A.L., Hassan, E.M., Georgiades, A.V., et al.: Asymptotic homogenization model for 3D grid-reinforced composite structures with generally orthotropic reinforcements. Compos. Struct. 89, 186–196 (2009)

Lapeyronnie, P., Grognec, P.L., Binétruy, C., et al.: Homogenization of the elastic behavior of a layer-to-layer angle-interlock composite. Compos. Struct. 93, 2795–2807 (2011)

Hollister, S.J., Kikuchi, N.: A comparison of homogenization and standard mechanics analyses for periodic porous composites. Comput. Mech. 10, 73–75 (1992)

Lefik, N., Schrefler, B.A.: 3D finite element analysis of composite beams with parallel fibres, based on homogenization theory. Comput. Mech 14, 2–15 (1994)

Liu, S.T., Cheng, G.D.: Study of predicting thermal conductivity of spherical porous material. J. Dalian. Univ. Technol. 34, 137–144 (1994) (in Chinese)

Liu, S.T., Cheng, G.D.: Study of the thermal conductivity of porous material. Comput. Struct. Mech. Appl. 11, 147–153 (1994) (in Chinese)

Liu, S.T., Zhang, Y.C.: Multi-Scale analysis method for thermal conductivity of porous material with radiation. MMMS 2, 327–344 (2006)

Berger, H., Gabbert, U., Koppe, H., et al.: Finite element and asymptotic homogenization methods applied to smart composite materials. Comput. Mech. 33, 61–67 (2003)

Liu, S.T., Cheng, G.D.: Homogenization-based method for predicting thermal expansion coefficients of composite materials. J. Dalian. Univ. Technol. 35, 451–457(1995) (in Chinese)

Terada, K., Kurumatani, M., Ushida, T., et al.: A method of two-scale thermo-mechanical analysis for porous solids with micro-scale heat transfer. Comput. Mech. 46, 269–285 (2010)

Cheng, G.D., Cai, Y.W., Xu, L.: Novel implementation of homogenization method to predict effective properties of periodic materials. Acta. Mech. Sin. 29, 550–556 (2013)

Cai, Y.W., Xu, L., Cheng, G.D.: Novel numerical implementation of asymptotic homogenization method for periodic plate structures. Int. J. Solids. Struct. 51, 284–292 (2014)

Wang, B., Tian, K., Hao, P., et al.: Hybrid analysis and optimization of hierarchical stiffened plates based on asymptotic homogenization method. Compos. Struct. 132, 136–147 (2015)

Xu, L., Cheng, G.D., Yi, S.N.: A new method of shear stiffness prediction of periodic Timoshenko beams. Mech. Adv. Mater. Struct. 23, 670–680 (2016)

Yi, S.N., Xu, L., Cheng, G.D., et al.: FEM formulation of homogenization method for effective properties of periodic heterogeneous beam and size effect of basic cell in thickness direction. Comput. Struct. 156, 1–11 (2015)

Yu, W.B., Tang, T.: A variational asymptotic micromechanics model for predicting thermoelastic properties of heterogeneous materials. Int. J. Solids. Struct. 44, 7510–7525 (2007)

Steeves, C.A., e Lucato, S.L.S., He, M.: Concepts for structurally robust materials that combine low thermal expansion with high stiffness. J. Mech. Phys. Solids. 55, 1803–1822 (2007)

Steeves, C.A., Mercer, C., Antinucci, E., et al.: Experimental investigation of the thermal properties of tailored expansion lattices. Int. J. Mech. Mater. Des. 5, 195–202 (2009)

Acknowledgements

The project was supported by the National Natural Science Foundation of China (Grants 11332004, 11572071), the Program for Changjiang Scholars and Innovative Research Team in Dalian University of Technology (PCSIRT), 111 Project (Grant B14013), and the CATIC Industrial Production Projects (Grant CXY2013DLLG32). We would also like to thank the Fundamental Research Funds for the Central Universities (Grant DUT15ZD101).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

This APDL command was used to compute the CTE of fiber reinforced composites.

FINISH

/CLEAR

/PREP7

/NERR,0

!! Geometric parameters

L=1

H=L

Y=L*L*H ! Volume of the unit cell

R= L/5 ! Radius of fiber

!! Material properties of fiber

EL1=23.1E9

ET1=233.1E9

GLT1=8.97E9

GTT1=8.28E9

VLT1=0.20

VTT1=0.40

AL1=-0.3E-6

AT1=5.6E-6

!! Material properties of matrix

E2=4.34E9

G2=1.59E9

V2=0.37

A2=24.4E-6

PI=3.1415926

!! Set element and material model

ET,1,SOLID185

MP,EX,1,EL1

MP,EY,1,EL1

MP,EZ,1,ET1

MP,NUXY,1,VTT1

MP,NUYZ,1,VLT1

MP,NUXZ,1,VLT1

MP,ALPX,1,AT1

MP,ALPY,1,AT1

MP,ALPZ,1,AL1

MP,GXY,1,GTT1

MP,GYZ,1,GLT1

MP,GXZ,1,GLT1

MP,EX,2,E2

MP,PRXY,2,V2

MP,ALPX,2,A2

!! Geometric model

WPOFF,,,-H/2

BLC5,,,L,L,H

CYL4,,,R,,,,H

VSBV,1,2

CYL4,,,R,,,,H

VGLUE,ALL

WPROTA,,-90

VSBW,ALL

WPROTA,,,90

VSBW,ALL

NUMCMP,ALL

WPROTA,,,45

VSEL,S,VOLU,,5,8,1

VSBW,ALL

ALLSEL,ALL

NUMCMP,ALL

WPROTA,,,90

VSEL,S,VOLU,,5,10,1

VSBW,ALL

NUMCMP,ALL

ALLSEL,ALL

!! Mesh generation

VSEL,S,VOLU,,1,4,1

VATT,1,,1

VSEL,S,VOLU,,5,12,1

VATT,2,,1

ALLSEL,ALL

CSYS,1

LSEL,S,LOC,Z,-L/2

LSEL,A,LOC,Z,L/2

LSEL,R,LOC,X,0,R/2+0.01

CM,L_1,LINE

LSEL,S,LOC,Z,-L/2

LSEL,A,LOC,Z,L/2

LSEL,R,LOC,X,R-0.01,R+0.01

CM,L_2,LINE

CSYS,0

LSEL,S,LOC,Z,0

CM,L_3,LINE

LSEL,ALL

CMSEL,U,L_1,LINE

CMSEL,U,L_2,LINE

CMSEL,U,L_3,LINE

LSEL,R,LOC,X,-L/2+0.01,L/2-0.01

LSEL,R,LOC,Y,-L/2+0.01,L/2-0.01

CM,L_4,LINE

CSYS,1

LSEL,S,LOC,X,(L/4+R/2)-0.01,(L/4+R/2)+0.01

CM,L_6,LINE

CSYS,0

CMSEL,S,L_4

CMSEL,U,L_6

CM,L_7,LINE

LSEL,ALL

CMSEL,U,L_1,LINE

CMSEL,U,L_2,LINE

CMSEL,U,L_3,LINE

CMSEL,U,L_4,LINE

CM,L_5,LINE

ALLSEL,ALL

LESIZE,L_3,,,4

LESIZE,L_1,,,6

LESIZE,L_2,,,6

LESIZE,L_5,,,6

LESIZE,L_6,,,5

LESIZE,L_7,,,5

ALLSEL, ALL

MSHAPE,0,3D

MSHKEY,1

VMESH,ALL

NUMMRG,ALL

NUMCMP,ALL

VGEN, ,ALL, , ,L/2,L/2,H/2, , ,1

!! Parameter definition

*GET,NNODE,NODE,0,COUNT

*DIM,X1,ARRAY,6,NNODE*3

*DIM,FX1,ARRAY,6,NNODE*3

*DIM,X2,ARRAY,6,NNODE*3

*DIM,XB2,ARRAY,1,NNODE*3

*DIM,FX2,ARRAY,6,NNODE*3

*DIM,FB1,ARRAY,1,NNODE*3

*DIM,FB2,ARRAY,1,NNODE*3

*DIM,EH,ARRAY,6,6

*DIM,EH0,ARRAY,6,6

*DIM,BETA,ARRAY,6,1

*DIM,ALPHA,ARRAY,6,1

!! Construct six (3d) nodal displacement fields

*DO,I,1,NNODE

X1(1,3*(I-1)+1)=NX(I)

X1(1,3*(I-1)+2)=0

X1(1,3*(I-1)+3)=0

*ENDDO

*DO,I,1,NNODE

X1(2,3*(I-1)+1)=0

X1(2,3*(I-1)+2)=NY(I)

X1(2,3*(I-1)+3)=0

*ENDDO

*DO,I,1,NNODE

X1(3,3*(I-1)+1)=0

X1(3,3*(I-1)+2)=0

X1(3,3*(I-1)+3)=NZ(I)

*ENDDO

*DO,I,1,NNODE

X1(4,3*(I-1)+1)=0

X1(4,3*(I-1)+2)=NZ(I)/2

X1(4,3*(I-1)+3)=NY(I)/2

*ENDDO

*DO,I,1,NNODE

X1(5,3*(I-1)+1)=NZ(I)/2

X1(5,3*(I-1)+2)=0

X1(5,3*(I-1)+3)=NX(I)/2

*ENDDO

*DO,I,1,NNODE

X1(6,3*(I-1)+1)=NY(I)/2

X1(6,3*(I-1)+2)=NX(I)/2

X1(6,3*(I-1)+3)=0

*ENDDO

*DO,II,1,2

*IF,II,EQ,1,THEN

! ! Solving the Eq. (17) and get the corresponding nodal reaction force

*DO,III,1,6

*DO,I,1,NNODE

D,I,UX,X1(III,3*(I-1)+1)

D,I,UY,X1(III,3*(I-1)+2)

D,I,UZ,X1(III,3*(I-1)+3)

*ENDDO

/SOLU

SOLVE

/POST1

*DO,I,1,NNODE

*GET,FX1(III,3*(I-1)+1),NODE,I,RF,FX

*GET,FX1(III,3*(I-1)+2),NODE,I,RF,FY

*GET,FX1(III,3*(I-1)+3),NODE,I,RF,FZ

*ENDDO

LSCLEAR,ALL

/PREP7

*ENDDO

*ELSEIF,II,EQ,2,THEN

! All the nodal degrees of freedom are fixed

ALLSEL,ALL

NSEL,ALL

D,ALL,UX,0

D,ALL,UY,0

D,ALL,UZ,0

! !Apply thermal loads (-1K) on each node

TREF,0

BFUNIF,TEMP,1

ALLSEL,ALL

! !Get the corresponding nodal reaction force

/SOLU

SOLVE

*DO,I,1,NNODE

*GET,FB1(1,3*(I-1)+1),NODE,I,RF,FX

*GET,FB1(1,3*(I-1)+2),NODE,I,RF,FY

*GET,FB1(1,3*(I-1)+3),NODE,I,RF,FZ

*ENDDO

*ENDIF

*ENDDO

LSCLEAR,ALL

/PREP7

*SET,LX,L

*SET,LY,L

*SET,LZ,H

! Set the periodic boundary conditions

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,0

CM,LINE_Z1,NODE

NSEL,S,LOC,X,LX

NSEL,R,LOC,Y,0

CM,LINE_Z2,NODE

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,LY

CM,LINE_Z3,NODE

NSEL,S,LOC,X,LX

NSEL,R,LOC,Y,LY

CM,LINE_Z4,NODE

CMSEL,S,LINE_Z1

CMSEL,A,LINE_Z2

CMSEL,A,LINE_Z3

CMSEL,A,LINE_Z4

CM,LINE_Z,NODE

NSEL,S,LOC,X,0

NSEL,R,LOC,Z,0

CM,LINE_Y1,NODE

NSEL,S,LOC,X,0

NSEL,R,LOC,Z,LZ

CM,LINE_Y2,NODE

NSEL,S,LOC,X,LX

NSEL,R,LOC,Z,0

CM,LINE_Y3,NODE

NSEL,S,LOC,X,LX

NSEL,R,LOC,Z,LZ

CM,LINE_Y4,NODE

CMSEL,S,LINE_Y1

CMSEL,A,LINE_Y2

CMSEL,A,LINE_Y3

CMSEL,A,LINE_Y4

CM,LINE_Y,NODE

NSEL,S,LOC,Y,0

NSEL,R,LOC,Z,0

CM,LINE_X1,NODE

NSEL,S,LOC,Y,LY

NSEL,R,LOC,Z,0

CM,LINE_X2,NODE

NSEL,S,LOC,Y,0

NSEL,R,LOC,Z,LZ

CM,LINE_X3,NODE

NSEL,S,LOC,Y,LY

NSEL,R,LOC,Z,LZ

CM,LINE_X4,NODE

CMSEL,S,LINE_X1

CMSEL,A,LINE_X2

CMSEL,A,LINE_X3

CMSEL,A,LINE_X4

CM,LINE_X,NODE

CMSEL,S,LINE_X

NSEL,R,LOC,X,0

CM,CORNER1,NODE

CMSEL,S,LINE_X

NSEL,R,LOC,X,LX

CM,CORNER2,NODE

CMSEL,S,CORNER1

CMSEL,A,CORNER2

CM,CORNER,NODE

CMSEL,S,CORNER

CP,NEXT,ALL,ALL

ALLSEL,ALL

CMSEL,S,LINE_X2

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,0,-LY,0,1,

CMSEL,U,LINE_X2

CM,LINE_X2_COPY,NODE

CMSEL,S,LINE_X3

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,0,0,-LZ,1,

CMSEL,U,LINE_X3

CM,LINE_X3_COPY,NODE

CMSEL,S,LINE_X4

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,0,-LY,-LZ,1,

CMSEL,U,LINE_X4

CM,LINE_X4_COPY,NODE

CMSEL,S,LINE_Y2

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,0,0,-LZ,1,

CMSEL,U,LINE_Y2

CM,LINE_Y2_COPY,NODE

CMSEL,S,LINE_Y3

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,-LX,0,0,1,

CMSEL,U,LINE_Y3

CM,LINE_Y3_COPY,NODE

CMSEL,S,LINE_Y4

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,-LX,0,-LZ,1,

CMSEL,U,LINE_Y4

CM,LINE_Y4_COPY,NODE

CMSEL,S,LINE_Z2

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,-LX,0,0,1,

CMSEL,U,LINE_Z2

CM,LINE_Z2_COPY,NODE

CMSEL,S,LINE_Z3

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,0,-LY,0,1,

CMSEL,U,LINE_Z3

CM,LINE_Z3_COPY,NODE

CMSEL,S,LINE_Z4

CMSEL,U,CORNER

NGEN,2,NNODE,ALL, , ,-LX,-LY,0,1,

CMSEL,U,LINE_Z4

CM,LINE_Z4_COPY,NODE

ALLSEL,ALL

CPINTF,ALL,0.0001,

CMSEL,S,LINE_X2_COPY

NGEN,2,0,ALL, , ,0,LY,0,1,

CMSEL,S,LINE_X3_COPY

NGEN,2,0,ALL, , ,0,0,LZ,1,

CMSEL,S,LINE_X4_COPY

NGEN,2,0,ALL, , ,0,LY,LZ,1,

CMSEL,S,LINE_Y2_COPY

NGEN,2,0,ALL, , ,0,0,LZ,1,

CMSEL,S,LINE_Y3_COPY

NGEN,2,0,ALL, , ,LX,0,0,1,

CMSEL,S,LINE_Y4_COPY

NGEN,2,0,ALL, , ,LX,0,LZ,1,

CMSEL,S,LINE_Z2_COPY

NGEN,2,0,ALL, , ,LX,0,0,1,

CMSEL,S,LINE_Z3_COPY

NGEN,2,0,ALL, , ,0,LY,0,1,

CMSEL,S,LINE_Z4_COPY

NGEN,2,0,ALL, , ,LX,LY,0,1,

ALLSEL,ALL

NPLOT

NUMMRG,NODE, , , ,LOW

NUMCMP,ALL

ALLSEL,ALL

CMSEL,U,LINE_X

CMSEL,U,LINE_Y

CMSEL,U,LINE_Z

CPCYC,ALL,1E-007,0,LX,0,0,0

CPCYC,ALL,1E-007,0,0,LY,0,0

CPCYC,ALL,1E-007,0,0,0,LZ,0

ALLSEL,ALL

*DO,II,1,2

*IF,II,EQ,1,THEN

! ! Solving the Eq. (13)

*DO,III,1,6

*DO,I,1,NNODE

F,I,FX,FX1(III,3*(I-1)+1)

F,I,FY,FX1(III,3*(I-1)+2)

F,I,FZ,FX1(III,3*(I-1)+3)

*ENDDO

! ! Fix one node to avoid the translational motion

NSEL,S, , , 480

D,ALL,ALL,0

ALLSEL,ALL

/SOLU

SOLVE

/POST1

*DO,I,1,NNODE

X2(III,3*(I-1)+1)=UX(I)

X2(III,3*(I-1)+2)=UY(I)

X2(III,3*(I-1)+3)=UZ(I)

*ENDDO

/PREP7

LSCLEAR,ALL

*ENDDO

*ELSIF,II,EQ,2,THEN

!! Solving the Eq. (22)

*DO,I,1,NNODE

F,I,FX,-FB1(1,3*(I-1)+1)

F,I,FY,-FB1(1,3*(I-1)+2)

F,I,FZ,-FB1(1,3*(I-1)+3)

*ENDDO

NSEL,S, , , 480

D,ALL,ALL,0

ALLSEL,ALL

/SOLU

SOLVE

/POST1

*DO,I,1,NNODE

XB2(1,3*(I-1)+1)=UX(I)

XB2(1,3*(I-1)+2)=UY(I)

XB2(1,3*(I-1)+3)=UZ(I)

*ENDDO

/PREP7

LSCLEAR,ALL

*ENDIF

*ENDDO

CPDELE,ALL

LSCLEAR,ALL

*DO,II,1,2

!! Solve the Eq. (21)

*IF,II,EQ,1,THEN

*DO,III,1,6

*DO,I,1,NNODE

D,I,UX,X2(III,3*(I-1)+1)

D,I,UY,X2(III,3*(I-1)+2)

D,I,UZ,X2(III,3*(I-1)+3)

*ENDDO

SOLVE

/POST1

*DO,I,1,NNODE

*GET,FX2(III,3*(I-1)+1),NODE,I,RF,FX

*GET,FX2(III,3*(I-1)+2),NODE,I,RF,FY

*GET,FX2(III,3*(I-1)+3),NODE,I,RF,FZ

*ENDDO

/PREP7

LSCLEAR,ALL

*ENDDO

*ELSEIF,II,EQ,2,THEN

*DO,I,1,NNODE

D,I,UX,XB2(1,3*(I-1)+1)

D,I,UY,XB2(1,3*(I-1)+2)

D,I,UZ,XB2(1,3*(I-1)+3)

*ENDDO

!! Solving the Eq. (27)

/SOLU

SOLVE

/POST1

*DO,I,1,NNODE

*GET,FB2(1,3*(I-1)+1),NODE,I,RF,FX

*GET,FB2(1,3*(I-1)+2),NODE,I,RF,FY

*GET,FB2(1,3*(I-1)+3),NODE,I,RF,FZ

*ENDDO

*ENDIF

*ENDDO

FINISH

/PREP7

VCLEAR,ALL

VDELE,ALL

ACLEAR,ALL

ADELE,ALL

LDELE,ALL

KDELE,ALL

/POST1

!Calculate the effective elastic matrix from Eq.(20)

*DO,I,1,6

*DO,J,1,6

EH(I,J)=0

*DO,K,1,NNODE*3

EH(I,J)=EH(I,J)+(X1(I,K)-X2(I,K))

*(FX1(J,K)-FX2(J,K))

*ENDDO

EH(I,J)=EH(I,J)/Y

*ENDDO

*ENDDO

! Calculate the effective thermoelastic constant beta

*DO,I,1,6

BETA(I)=0

*DO,K,1,NNODE*3

BETA(I)=BETA(I)+X1(I,K)*(-FB1(1,K)-FB2(1,K))

*ENDDO

BETA(I)=BETA(I)/Y

*ENDDO

!! Calculate the effective CTE from Eq. (8)

*MOPER,EH0,EH,INVERT

*MOPER,ALPHA,EH0,MULT,BETA

! Output the results into one file

*CFOPEN,H_RESULT,DAT,,APPEND

*VWRITE,R

%15.10F

*VWRITE,

(’ The effective elastic matrix ’)

*VWRITE,EH(1,1),EH(1,2),EH(1,3),

EH(1,4),EH(1,5),EH(1,6)

(6(1PE15.6))

*VWRITE,

(’ The effective thermoelastic constant- beta’)

*VWRITE,BETA(1,1),BETA(2,1),BETA(3,1),

BETA(4,1),BETA(5,1),BETA(6,1)

(6(1PE15.6))

*VWRITE,

(’ The effective CTE-alpha’)

*VWRITE,ALPHA(1,1),ALPHA(2,1),ALPHA(3,1),

ALPHA(4,1),ALPHA(5,1),ALPHA(6,1)

(6(1PE15.6)/)

*CFCLOSE.

Rights and permissions

About this article

Cite this article

Zhang, Y., Shang, S. & Liu, S. A novel implementation algorithm of asymptotic homogenization for predicting the effective coefficient of thermal expansion of periodic composite materials. Acta Mech. Sin. 33, 368–381 (2017). https://doi.org/10.1007/s10409-016-0618-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-016-0618-7