Abstract

The residual stresses in the wall of a SUS304 stainless steel cylindrical drawing cup were evaluated by split-ring tests, and the influences of stamping die parameters on the residual stress were investigated. A new theoretical model of a split-ring test was developed to evaluate the residual stress in a ring, which was verified to be reasonable and reliable by numerical simulations with ABAQUS code and by nanoindentation tests. Seven groups of split-ring tests were completed, and the residual stresses were calculated according to the theoretical model. The split-ring test results showed that the circumferential residual stress in the wall of the SUS304 stainless steel cylindrical drawing cup was very large and did not change with the different die corner radius. The circumferential residual stress first increased with the increase of drawing punch–die clearance, then was almost unchanged when the clearance increased greater than blank thickness 1 mm. Thus, a smaller clearance was suggested to be chosen to reduce the residual stress in the wall of the SUS304 stainless steel drawing cup.

Graphical Abstract

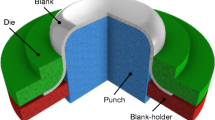

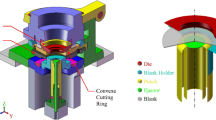

Seven groups, three samples in each group, and a total of 21 qualified cylindrical drawing cups in Fig. 2 were made from a circular SUS304 stainless steel sheet about 72 mm in diameter and 0.94 mm in thickness by deep drawing with different processing parameters. After the rings were cut from the cup walls, each ring was split along the radial direction. Two ends of each split ring opened a distance to release the circumferential residual stress in the closed ring. After measuring the opening distance, the residual stresses in the drawing cup walls were calculated by Eq. (18) in the newly developed split-ring test theoretical model of this paper. Then reasonable technology measures were found to reduce the residual stress by analyzing the influence of the mold parameters on residual stresses.

Similar content being viewed by others

References

Rossini, N.S., Dassisti, M., Benyounis, K.Y., et al.: Methods of measuring residual stresses in components. Mater. Des. 35, 572–588 (2012)

Trufyakov, V., Mikheev, P., Kudryavtsev, Y.F., et al.: Fatigue endurance of welded joints. Residual stresses and fatigue improvement treatments. In: Ship Structure Symposium’93, Arlington, Virginia, USA (1993)

Carpenter, H.W., Reid, R.G., Paskaramoorthy, R.: Measurement of the distribution of residual stresses in layered thick-walled GFRP pipes. Exp. Mech. 54, 1627–1638 (2014)

Buchmann, M., Gadow, R., Tabellion, J.: Experimental and numerical residual stress analysis of layer coated composites. Mater. Sci. Eng. A 288, 154–159 (2000)

Basrour, S., Robert, L., Delobell, P.: Measurement of residual stresses in a plate using bulging test and a dynamic technique: Application to electroplated nickel coatings. Mater. Sci. Eng. A 288, 160–163 (2000)

Wu, Q., Li, D.P.: Analysis and X-ray measurements of cutting residual stresses in 7075 aluminum alloy in high speed machining. Int. J. Precis. Eng. Manuf. 15, 1499–1506 (2014)

Papahn, H., Bahemmat, P., Haghpanahi, M., et al.: Ultrasonic measurements of residual stresses caused by severe thermo-mechanical deformation during FSW. Exp. Mech. 54, 1587–1596 (2014)

Taylor, C.A., Wayne, M.F.: Residual stress measurement in thin carbon films by Raman spectroscopy and nanoindentation. Thin Solid Films 429, 190–200 (2003)

Bai, M.Y., Liu, L.Y., Wu, J.F., et al.: Failure analysis on cracking of cartridge case. Phys. Test. Chem. Anal. A 3, 180–184 (2011)

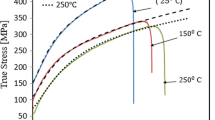

Grèze, R., Manach, P.Y., Laurent, H., et al.: Influence of the temperature on residual stresses and springback effect in an aluminium alloy. Int. J. Mech. Sci. 52, 1094–1100 (2010)

Laurent, H., Grèze, R., Manach, P.Y., et al.: Influence of constitutive model in springback prediction using the split-ring test. Int. J. Mech. Sci. 51, 233–245 (2009)

Oliveira, M.C., Alves, J.L., Chaparro, B.M., et al.: Study on the influence of work-hardening modeling in springback prediction. Int. J. Plast. 23, 516–543 (2007)

Tekıner, Z.: An experimental study on the examination of springback of sheet metals with several thicknesses and properties in bending dies. J. Mater. Process. Technol. 145, 109–117 (2004)

Inamdar, M.V., Date, P.P., Sabnis, S.V.: On the effects of geometric parameters on springback in sheets of five materials subjected to air vee bending. J. Mater. Process. Technol. 123, 459–463 (2002)

Lee, M.G., Kim, S.J., Wagoner, R.H., et al.: Constitutive modeling for anisotropic/asymmetric hardening behavior of magnesium alloy sheets: Application to sheet springback. Int. J. Plast. 25, 70–104 (2009)

Livatyali, H., Altan, T.: Prediction and elimination of springback in straight flanging using computer aided design methods: Part 1. Experimental investigations. J. Mater. Process. Technol. 117, 262–268 (2001)

Xia, Z.C., Miller, C.E., Ren, F.: Experimental and numerical investigations of a split-ring test for springback. Trans. ASME B 129, 352–359 (2007)

Huang, Y.H., Xuan, F.Z., Tu, S.T.: Study on stress corrosion property of 304 austenitic stainless steel in the environment of acid chloride solution. Press. Vessels 26, 5–10 (2009)

Hurley, M.F., Olson, C.R., Ward, L.J., et al.: Transgranular stress corrosion cracking of 304L stainless steel pipe clamps in direct use geothermal water heating applications. Eng. Fail. Anal. 33, 336–346 (2013)

Alyousif, O.M., Nishimura, R.: Stress corrosion cracking and hydrogen embrittlement of sensitized austenitic stainless steels in boiling saturated magnesium chloride solutions. Corros. Sci. 50, 2353–2359 (2008)

Nishimura, R., Maeda, Y.: SCC evaluation of type 304 and 316 austenitic stainless steels in acidic chloride solutions using the slow strain rate technique. Corros. Sci. 46, 769–785 (2004)

Timofeev, B.T., Fedorova, V.A., Buchatskii, A.A.: Intercrystalline corrosion cracking of power equipment made of austenitic steels (review). Annu. Rev. Mater. Sci. 40, 48–59 (2004)

Gutman, E.M., Solovioff, G., Eliezer, D.: The mechanochemical behavior of type 316L stainless steel. Corros. Sci. 38, 1141–1145 (1996)

Shen, Y.F., Li, X.X., Xue, W.Y., et al.: Changes in martensite fraction of 304SS in tensile deformation. J. Northeast. Univ. (Nat. Sci.) 33, 1125–1128 (2012)

Hecker, S.S., Stout, M.G., Staudhammer, K.P., et al.: Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: Part I. Magnetic measurements and mechanical behavior. Metall. Trans. A 13, 619–626 (1982)

De, A.K., Speer, J.G., Matlock, D.K., et al.: Deformation-induced phase transformation and strain hardening in type 304 austenitic stainless steel. Metall. Mater. Trans. A 37, 1875–1886 (2006)

Mousavi Akbari, S.A.A., Miresmaeili, R.: Experimental and numerical analyses of residual stress distributions in TIG welding process for 304L stainless steel. J. Mater. Process. Technol. 208, 383–394 (2008)

Ma, Z., Li, Y.H., Zhang, Y.K., et al.: Influence of laser shock processing on mechanical property of SUS304 steel. Trans. Mater. Heat Treat. 28, 102–105 (2007)

Deng, D., Murakawa, H.: Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput. Mater. Sci. 37, 269–277 (2006)

Laurent, H., Grèze, R., Oliveira, M.C., et al.: Numerical study of springback using the split-ring test for an AA5754 aluminum alloy. Finite Elem. Anal. Des. 46, 751–759 (2010)

Lin, Z., Wang, Y.L., Lin, J.P., et al.: The experimental principle of Nano indenter II and its applications. J. Aeronaut. Mater. 21, 56–62 (2001)

Oliver, W.C., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiment. J. Mater. Res. 7, 1564–1583 (1992)

Suresh, S., Giannakopoulos, A.E.: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755–5767 (1998)

Berrahmoune, M.R., Berveiller, S., Inal, K., et al.: Delayed cracking in 301LN austenitic steel after deep drawing: Martensitic transformation and residual stress analysis. Mater. Sci. Eng. A 438, 262–266 (2006)

Acknowledgments

This work was supported in part by Xiangtan University Doctoral Fund, China (Grant 12QDZ17), the Excellent Youth Program of Education Bureau of Hunan Province, China (Grant 12B124), and the Key Program of Hunan Provincial Natural Science Foundation United with Xiangtan, China (Grant 13JJ8005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, LH., Yuan, DH., Xiang, JZ. et al. Residual stress in the cylindrical drawing cup of SUS304 stainless steel evaluated by split-ring test. Acta Mech. Sin. 32, 125–134 (2016). https://doi.org/10.1007/s10409-015-0516-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-015-0516-4