Abstract

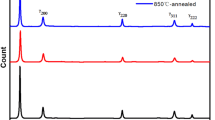

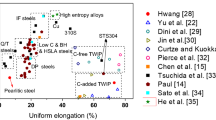

In order to improve the mechanical properties of twinning-induced plasticity steel, the grain morphology was tailored by different solidification technologies combined with deformation and heat treatment processing routes. Three typical grain morphologies, i.e., equiaxed, columnar as well as equiaxed/columnar grains were formed, and their mechanical behaviors were comparatively studied. Among the three materials, the equiaxed grain material exhibited the highest strength but the lowest plasticity. Depending on the grain size, the smaller the grain size, the higher the strength, but the lower the elongation. The columnar grain material possessed the most excellent plasticity but the weakest strength. These properties presented a non-monotonic dependence on the dendrite spacing, and the moderate spacing resulted in the optimum combination of strength and plasticity. The equiaxed/columnar grain coexisted material showed interesting properties, i.e., the strength and plasticity were just between those of single grain-shaped materials. The three materials also presented different strain hardening behaviors particularly in the uniform deformation stage. The equiaxed grain material showed a constant strain hardening rate, while the columnar grain and equiaxed/columnar grain materials showed a progressively increasing rate with increasing the true strain.

Graphical abstract

The introduction of equiaxed grains into the columnar grain material obviously enhances the strength but weakens the plasticity of the material. However, it seems that an appropriate amount of equiaxed grains will provide the material an optimum combination of strength and plasticity.

Similar content being viewed by others

References

Frommeyer, G., Brux, U., Neumann, P.: Supra-ductile and high-strength manganese-TRIP/TWIP steels for high energy absorption purposes. ISIJ Int. 43, 438–446 (2003)

Grassel, O., Frommeyer, G., Derder, C., et al.: Phase transformations and mechanical properties of Fe-Mn-Si-Al TRIP-steels. J. Phys. IV 7, 383–388 (1997)

Grassel, O., Kruger, L., Frommeyer, G., et al.: High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development–properties–application. Int. J. Plast. 16, 1391–1409 (2000)

Mi, Z.L., Tang, D., Yan, L., et al.: High-strength and high-plasticity TWIP steel for modern vehicle. J. Mater. Sci. Technol. 21, 451–454 (2005)

Vercammen, S., Blanpain, B., De Cooman, B.C., et al.: Cold rolling behaviour of an austenitic, Fe-30Mn-3Al-3Si TWIP-steel: the importance of deformation twinning. Acta Mater. 52, 2005–2012 (2004)

Yan, K., Carr, D.G., Callaghan, M.D., et al.: Deformation mechanisms of twinning-induced plasticity steels: In situ synchrotron characterization and modeling. Scr. Mater. 62, 246–249 (2010)

Duan, X., Wang, D., Wang, K., et al.: Twinning behaviour of TWIP steel studied by Taylor factor analysis. Philos. Mag. Lett. 93, 316–321 (2013)

Saha, R., Ueji, R., Tsuji, N.: Fully recrystallized nanostructure fabricated without severe plastic deformation in high-Mn austenitic steel. Scr. Mater. 68, 813–816 (2013)

Dini, G., Najafizadeh, A., Ueji, R., et al.: Tensile deformation behavior of high manganese austenitic steel: The role of grain size. Mater. Des. 31, 3395–3402 (2010)

Ueji, R., Tsuchida, N., Terada, D., et al.: Tensile properties and twinning behavior of high manganese austenitic steel with fine-grained structure. Scr. Mater. 59, 963–966 (2008)

Peng, X., Zhu, D., Hu, Z., et al.: Stacking fault energy and tensile deformation behavior of high-carbon twinning-induced plasticity steels: Effect of Cu addition. Mater. Des. 45, 518–523 (2013)

Curtze, S., Kuokkala, V.T.: Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 58, 5129–5141 (2010)

Wang, D., Wang, K., Shi, Z.M., et al.: The mechanical and deformation behavior of TWIP steel prepared by directional solidification. Mater. Sci. Forum 783–786, 761–765 (2014)

Bouaziz, O., Allain, S., Scott, C.: Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels. Scr. Mater. 58, 484–487 (2008)

Gutierrez-Urrutia, I., Raabe, D.: Grain size effect on strain hardening in twinning-induced plasticity steels. Scr. Mater. 66, 992–996 (2012)

Lee, T., Koyama, M., Tsuzaki, K., et al.: Tensile deformation behavior of Fe-Mn-C TWIP steel with ultrafine elongated grain structure. Mater. Lett. 75, 169–171 (2012)

Idrissi, H., Renard, K., Ryelandt, L., et al.: On the mechanism of twin formation in Fe-Mn-C TWIP steels. Acta Mater. 58, 2464–2476 (2010)

Gutierrez-Urrutia, I., Raabe, D.: Dislocation and twin substructure evolution during strain hardening of an Fe-22 wt.% Mn-0.6 wt.% C TWIP steel observed by electron channeling contrast imaging. Acta Mater. 59, 6449–6462 (2011)

Lu, L., Shen, Y., Chen, X., et al.: Ultrahigh strength and high electrical conductivity in copper. Science 304, 422–426 (2004)

Gutierrez-Urrutia, I., Zaefferer, S., Raabe, D.: The effect of grain size and grain orientation on deformation twinning in a Fe-22wt.% Mn-0.6wt.% C TWIP steel. Mater. Sci. Eng. A 527, 3552–3560 (2010)

Gutierrez-Urrutia, I., Raabe, D.: Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe-Mn-Al-C steel. Acta Mater. 60, 5791–5802 (2012)

Acknowledgments

This work was jointly supported by the key direction project of Chinese Academy of Sciences on the high speed rail and the National Natural Science Foundation of China (Grant 51371167).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, K., Wang, D. & Han, F. Effect of crystalline grain structures on the mechanical properties of twinning-induced plasticity steel. Acta Mech. Sin. 32, 181–187 (2016). https://doi.org/10.1007/s10409-015-0513-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-015-0513-7