Abstract

The dynamics of inkjet deposition in square microcavities are investigated utilizing a three-dimensional multi-relaxation-time pseudopotential lattice Boltzmann (LB) model with large density ratios. A geometric scheme is considered within the pseudopotential LBM framework to obtain the desired contact angles. The effects of wettability, density ratios, droplet viscosity and impact velocity are explored to reveal the droplet–microcavity interactions. With the contact angles of microcavity increasing, the physical outcomes including the crown-like shape with a small round dot, circular hollow core, uniform film and convex film are identified and analyzed. At a lower density ratio ρr = 11.6, the surrounding denser gas resists the droplet recoiling flow resulting in an increasing hollow core. The appropriate higher droplet viscosity and decreasing impact velocity are preferred which could eliminate the hollow core in the recoiling phase and accelerate the inkjet deposition process straightforward. The revelation of droplet-microcavity dynamics is beneficial for optimizing inkjet deposition process and fabricating uniform OLEDs panels.

Similar content being viewed by others

References

Benzi R, Biferale L, Sbragaglia M, Succi S, Toschi F (2006) Mesoscopic modeling of a two-phase flow in the presence of boundaries: the contact angle. Phys Rev E 74:021509

Chen S, Doolen GD (2003) Lattice Boltzmann method for fluid flow. Annu Rev Fluid Mech 30:329–364

Connington K, Lee T (2013) Lattice Boltzmann simulations of forced wetting transitions of drops on superhydrophobic surfaces. J Comput Phys 250:601–615

Derby B (2010) Inkjet printing of functional and structural materials: fluid property requirements, feature stability, and resolution. Annu Rev Mater Res 40:395–414

Ding H, Spelt PDM (2007) Wetting condition in diffuse interface simulations of contact line motion. Phys Rev E 75:046708

Ding H, Theofanous TG (2011) The inertial regime of drop impact on an anisotropic porous substrate. J Fluid Mech 691:546–567

Dong H, Carr WW, Bucknall DG, Morris JF (2007) Temporally-resolved inkjet drop impaction on surfaces. AIChE J 53:2606–2617

Dupuis A, Yeomans JM (2005) Modeling droplets on superhydrophobic surfaces: equilibrium states and transitions. Langmuir 21:2624–2629

Enríquez OR, Meer DD (2014) Exploring droplet impact near a millimetre-sized hole: comparing a closed pit with an open-ended pore. J Fluid Mech 772:427–444

Gorter H, Coenen MJJ, Slaats MWL, Ren M, Lu W, Kuijpers CJ, Groen WA (2013) Toward inkjet printing of small molecule organic light emitting diodes. Thin Solid Films 532:11–15

Ju Y, Kuo F, Lin Y, Huang T, Lin C (2017) Partial wetting boundary conditions on micro-structure surface for Lattice Boltzmann method. Comput Fluids 142:37–44

Krüger T, Kusumaatmaja H, Kuzmin A, Shardt O, Silva G, Viggen EM (2017) The lattice Boltzmann method: principles and practice. Springer, Switzerland

Lallemand P, Luo LS (2000) Theory of the lattice Boltzmann method: dispersion, dissipation, isotropy, Galilean invariance, and stability. Phys Rev E 61:6546

Lee T, Liu L (2010) Lattice Boltzmann simulations of micron-scale drop impact on dry surfaces. J Comput Phys 229:8045–8063

Li Q, Luo KH, Li XJ (2012) Forcing scheme in pseudopotential lattice Boltzmann model for multiphase flows. Phys Rev E 86:016709

Li Q, Luo KH, Li XJ (2013) Lattice Boltzmann modeling of multiphase flows at large density ratio with an improved pseudopotential model. Phys Rev E 87:053301

Liou T, Chan C, Fu C, Shih K (2008) Effects of impact inertia and surface characteristics on deposited polymer droplets in microcavities. J Microelectromechanical Syst 17:278–287

Liou T, Chan C, Shih K (2009) Study of the characteristics of polymer droplet deposition in fabricated rectangular microcavities. J Micromech Microeng 19:065028

Luo LS (2000) Theory of the lattice boltzmann method: lattice boltzmann models for nonideal gases. Phys Rev E 62:4982

Martys NS, Chen H (1996) Simulation of multicomponent fluids in complex three-dimensional geometries by the lattice Boltzmann method. Phys Rev E 53:743

Miers JC, Zhou W (2017) Droplet formation at megahertz frequency. AIChE J 63:2367–2377

Rein M (1993) Phenomena of liquid drop impact on solid and liquid surfaces. Fluid Dyn Res 12:61–93

Rioboo R, Marengo M, Tropea C (2002) Time evolution of liquid drop impact onto solid, dry surfaces. Exp Fluids 33:112–124

Shi Y, Tang GH, Xia HH (2015) Investigation of coalescence-induced droplet jumping on superhydrophobic surfaces and liquid condensate adhesion on slit and plain fins. Int J Heat Mass Transf 88:445–455

Shimoda T, Morii K, Seki S, Kiguchi H (2003) Inkjet printing of light-emitting polymer displays. MRS Bull 28:821–827

Subramani HJ, Al-Housseiny T, Chen AU, Li M, Basaran OA (2007) Dynamics of drop impact on a rectangular slot. Ind Eng Chem Res 46:6105–6112

Suh Y, Son G (2010) Numerical simulation of droplet deposition and Self-Alignment on a microstructured surface. Numer Heat Transf A Appl 57:415–430

Sun RG, Wang YZ, Wang DK, Zheng QB, Kyllo EM, Gustafson TL, Epstein AJ (2000) High luminescent efficiency in light-emitting polymers due to effective exciton confinement. Appl Phys Lett 76:634–636

Villani F, Vacca P, Nenna G, Valentino O, Burrasca G, Fasolino T, Minarini C, Della Sala D (2009) Inkjet printed polymer layer on flexible substrate for OLED applications. J Phys Chem C 113:13398–13402

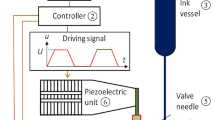

Wijshoff H (2010) The dynamics of the piezo inkjet printhead operation. Phys Rep 491:77–177

Yan YY, Zu YQ (2007) A lattice Boltzmann method for incompressible two-phase flows on partial wetting surface with large density ratio. J Comput Phys 227:763–775

Yarin AL (2006) Drop impact dynamics: splashing, spreading, receding, bouncing. Annu Rev Fluid Mech 38:159–192

Yokoi K, Vadillo D, Hinch J, Hutchings I (2009) Numerical studies of the influence of the dynamic contact angle on a droplet impacting on a dry surface. Phys Fluids 21:145–148

Yuan P, Schaefer L (2006) Equations of state in a lattice Boltzmann model. Phys Fluids 18:042101

Zhang L, Zhu Y, Cheng X (2017) Numerical investigation of multi-droplets deposited lines morphology with a multiple-relaxation-time lattice Boltzmann model. Chem Eng Sci 171:534–544

Zheng H, Zheng Y, Liu N, Ai N, Wang Q, Wu S, Zhou J, Hu D, Yu S, Han S (2013) All-solution processed polymer light-emitting diode displays. Nat Commun 4:1971

Acknowledgements

This research work is supported by the National Key Research and Development Program of China through Grant No. 2017YFB0306401.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Ku, T., Cheng, X. et al. Inkjet droplet deposition dynamics into square microcavities for OLEDs manufacturing. Microfluid Nanofluid 22, 47 (2018). https://doi.org/10.1007/s10404-018-2068-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-018-2068-y