Abstract

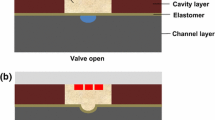

Various microfluidic architectures designed for in vivo and point-of-care diagnostic applications require larger channels, autonomous actuation, and portability. In this paper, we present a normally closed microvalve design capable of fully autonomous actuation for wide diameter microchannels (tens to hundreds of µm). We fabricated the multilayer plunger-membrane valve architecture using the silicone elastomer, poly-dimethylsiloxane (PDMS) and optimized it to reduce the force required to open the valve. A 50-µm Nitinol (NiTi) shape memory alloy wire is incorporated into the device and can operate the valve when actuated with 100-mA current delivered from a 3-V supply. We characterized the valve for its actuation kinetics using an electrochemical assay and tested its reliability at 1.5-s cycle duration for 1 million cycles during which we observed no operational degradation.

Similar content being viewed by others

References

Amin AM, Thakur R, Madren S et al (2013) Software-programmable continuous-flow multi-purpose lab-on-a-chip. Microfluid Nanofluidics. https://doi.org/10.1007/s10404-013-1180-2

Au AK, Lai H, Utela BR, Folch A (2011) Microvalves and micropumps for BioMEMS. Micromachines 2:179–220. https://doi.org/10.3390/mi2020179

Augustine S, Gu P, Zheng X et al (2015) Low-power electrically controlled thermoelastic microvalves integrated in thermoplastic microfluidic devices. Microfluid Nanofluidics 19:1385–1394. https://doi.org/10.1007/s10404-015-1653-6

Baek JY, Park JY, Il JuJ et al (2005) A pneumatically controllable flexible and polymeric microfluidic valve fabricated via in situ development. J. Micromechanics Microengineering 15:1015–1020. https://doi.org/10.1088/0960-1317/15/5/017

Chen H, Gu W, Cellar N et al (2008) Electromechanical properties of pressure-actuated poly (dimethylsiloxane) microfluidic push-down valves. Anal. Chem. 80:6110–6113

Chen S, Lu S, Liu Y et al (2016) A normally-closed piezoelectric micro-valve with flexible stopper. AIP Adv. https://doi.org/10.1063/1.4947301

Chuang H-S, Thakur R, Wereley ST (2012) Characterizations of gas purge valves for liquid alignment and gas removal in a microfluidic chip. J Micromechanics Microengineering. https://doi.org/10.1088/0960-1317/22/8/085023

Desai AV, Tice JD, Apblett CA, Kenis PJA (2012) Design considerations for electrostatic microvalves with applications in poly(dimethylsiloxane)-based microfluidics. Lab Chip 12:1078. https://doi.org/10.1039/c2lc21133e

Díaz-González M, Fernández-Sánchez C, Baldi A (2016) Multiple actuation microvalves in wax microfluidics. Lab Chip. https://doi.org/10.1039/C6LC00800C

Evans AT, Park JM, Chiravuri S, Gianchandani YB (2010) A low power, microvalve regulated architecture for drug delivery systems. Biomed. Microdevices 12:159–168. https://doi.org/10.1007/s10544-009-9372-y

Gui L, Ren CL (2011) Exploration and evaluation of embedded shape memory alloy (SMA) microvalves for high aspect ratio microchannels. Sensors Actuators A Phys. 168:155–161. https://doi.org/10.1016/j.sna.2011.03.038

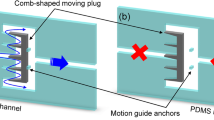

Guler MT, Beyazkilic P, Elbuken C (2017) A versatile plug microvalve for microfluidic applications. Sensors Actuators A Phys. 265:224–230. https://doi.org/10.1016/j.sna.2017.09.001

Herr AE, Hatch AV, Throckmorton DJ et al (2007) Microfluidic immunoassays as rapid saliva-based clinical diagnostics. Proc. Natl. Acad. Sci. 104:5268–5273. https://doi.org/10.1073/pnas.0607254104

Jang L-W, Razu ME, Jensen EC et al (2016) A fully automated microfluidic micellar electrokinetic chromatography analyzer for organic compound detection. Lab Chip 16:3558–3564. https://doi.org/10.1039/C6LC00790B

Jensen EC, Stockton AM, Chiesl TN et al (2013) Digitally programmable microfluidic automaton for multiscale combinatorial mixing and sample processing. Lab Chip 13:288–296. https://doi.org/10.1039/C2LC40861A

Kim J, Kang M, Jensen EC, Mathies RA (2012) Lifting gate polydimethylsiloxane microvalves and pumps for microfluidic control. Anal. Chem. 84:2067–2071. https://doi.org/10.1021/ac202934x

Kim J, Stockton AM, Jensen EC, Mathies RA (2016) Pneumatically actuated microvalve circuits for programmable automation of chemical and biochemical analysis. Lab Chip 16:812–819. https://doi.org/10.1039/C5LC01397F

Mark D, Haeberle S, Roth G et al (2010) Microfluidic lab-on-a-chip platforms: requirements, characteristics and applications. NATO Sci. Peace Secur. Ser. A Chem. Biol. https://doi.org/10.1007/978-90-481-9029-4-17

Mohan R, Schudel BR, Desai AV et al (2011) Design considerations for elastomeric normally closed microfluidic valves. Sensors Actuators B Chem. 160:1216–1223. https://doi.org/10.1016/j.snb.2011.09.051

Oh KW, Ahn CH (2006) A review of microvalves. J. Micromechanics Microengineering 16:R13–R39. https://doi.org/10.1088/0960-1317/16/5/R01

Rogers CI, Oxborrow JB, Anderson RR et al (2014) Microfluidic valves made from polymerized polyethylene glycol diacrylate. Sensors Actuators B Chem. 191:438–444. https://doi.org/10.1016/j.snb.2013.10.008

Vyawahare S, Sitaula S, Martin S et al (2008) Electronic control of elastomeric microfluidic circuits with shape memory actuators. Lab Chip 8:1530. https://doi.org/10.1039/b804515a

Weibel DB, Kruithof M, Potenta S et al (2005) Torque-actuated valves for microfluidics. Anal Chem 77:4726–4733. https://doi.org/10.1021/ac048303p

Acknowledgements

We thank Kevin King, Annie Mao, and Scott Sterrett for previous microfluidics work toward safe DC stimulator design. We also acknowledge the funding sources that made this work possible: MedEl Corporate Grant: FK2350 and NIH R01NS092726.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, C., Nair, A.R., Thakur, R. et al. Normally closed plunger-membrane microvalve self-actuated electrically using a shape memory alloy wire. Microfluid Nanofluid 22, 29 (2018). https://doi.org/10.1007/s10404-018-2049-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-018-2049-1