Abstract

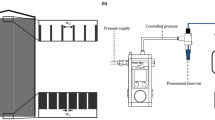

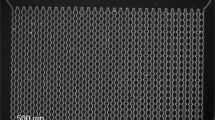

The aim of this work is to study the pore blocking by the use of microfluidic devices (microseparators) and numerical simulation approaches. The microseparators are made in PDMS and are constituted of an array of microchannels 20 μm wide with three types of structure: straight microchannels, connected microchannels (or aligned square pillars) and staggered square pillars in order to mimic merely the complexity of the flow encountered in filters or membranes (tortuosity, connectivity between pores). Direct observation with video microscopy of filtrations of 5 μm latex particles has been performed to examine the capture of particles. The results show a piling up of particles within the porous media leading to a clogging. The capture efficiency remains low (<0.1 %). In the case of filtration in the forest of pillars, the capture is faster and arises mainly between the pillars. The increase in tortuosity in the microseparator leads then to a rise of the clogging. It must be caused by the increase in critical trajectories leading to the capture of particles on the PDMS walls. At the same time, numerical simulations of filtration in parallel with microchannels have been performed in the same flow conditions with GeoDict software. The different kind of experimental deposit structure can be simulated, but there is still inaccuracy in the description of the accumulation kinetics. These discrepancies are probably due to the lack of accuracy to depict particle/particle colloidal interactions in simulations and the fact that re-suspension of particles after capture is not well described.

Similar content being viewed by others

References

Agbangla GC, Climent E, Bacchin P (2012) Experimental investigation of pore clogging by microparticles: evidence for a critical flux density of particle yielding arches and deposits. Sep Purif Technol 101:42–48

Ando T, Akamatsu K, Nakao S, Fujita M (2012) Simulation of fouling and backwash dynamics in dead-end microfiltration: effect of pore size. J Membr Sci 392–393:48–57

Bacchin P, Aimar P, Field RW (2006a) Critical and sustainable fluxes: theory, experiments and applications. J Membr Sci 281:42–69

Bacchin P, Espinasse B, Bessiere Y, Fletcher DF, Aimar P (2006b) Numerical simulation of colloidal dispersion filtration: description of critical flux and comparison with experimental results. Desalination 192:74–81

Bacchin P, Marty A, Duru P, Meireles M, Aimar P (2011) Colloidal surface interactions and membrane fouling: investigations at pore scale. Adv Colloid Interface Sci 164:2–11

Bessiere Y, Abidine N, Bacchin P (2005) Low fouling conditions in dead-end filtration: evidence for a critical filtered volume and interpretation using critical osmotic pressure. J Membr Sci 264:37–47

Bowen WR, Filippov AN, Sharif AO, Starov VM (1999) A model of the interaction between a charged particle and a pore in a charged membrane surface. Adv Colloid Interface Sci 81:35–72

Bromley A, Holdich R, Cumming I (2002) Particulate fouling of surface microfilters with slotted and circular pore geometry. J Membr Sci 196:27–37

Chandler M, Zydney A (2006) Effects of membrane pore geometry on fouling behavior during yeast cell microfiltration. J Membr Sci 285:334–341

Chatterjee R, Bhattacharjee S, Mitra SK (2012) Particle transport in patterned cylindrical microchannels. Microfluid Nanofluid 12:41–51

Chen JC, Li Q, Elimelech M (2004) In situ monitoring techniques for concentration polarization and fouling phenomena in membrane filtration. Adv Colloid Interface Sci 107:83–108

Elimelech M, O’Melia CR (1990) Kinetics of deposition of colloidal particles in porous media. Environ Sci Technol 24:1528–1536

Grenier A, Meireles M, Aimar P, Carvin P (2008) Analysing flux decline in dead-end filtration. Chem Eng Res Des 86:1281–1293

Gudipaty T, Stamm MT, Cheung LSL, Jiang L, Zohar Y (2011) Cluster formation and growth in microchannel flow of dilute particle suspensions. Microfluid Nanofluid 10:661–669

Henry C, Minier J-P, Lefèvre G (2012) Towards a description of particulate fouling: from single particle deposition to clogging. Adv Colloid Interface Sci 185–186:34–76

Hermia J (1982) Constant pressure blocking filtration law application to powder-law non-Newtonian fluid. Trans Inst Chem Eng 60:183–187

Kim M, Zydney AL (2004) Effect of electrostatic, hydrodynamic, and Brownian forces on particle trajectories and sieving in normal flow filtration. J Colloid Interface Sci 269:425–431

Kuiper S, van Rijn CJ, Nijdam W, Krijnen GJ, Elwenspoek M (2000) Determination of particle-release conditions in microfiltration: a simple single-particle model tested on a model membrane. J Membr Sci 180:15–28

Lin J, Bourrier D, Dilhan M, Duru P (2009) Particle deposition onto a microsieve. Phys Fluids 21:073301–0733014

McDonald JC, Duffy DC, Anderson JR, Chiu DT, Wu H, Schueller OJA, Whitesides GM (2000) Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 21:27–40

Mustin B, Stoeber B (2010) Deposition of particles from polydisperse suspensions in microfluidic systems. Microfluid Nanofluid 9:905–913

Ramachandran V, Fogler HS (1998) Multilayer deposition of stable colloidal particles during flow within cylindrical pores. Langmuir 14:4435–4444

Ramachandran V, Fogler HS (1999) Plugging by hydrodynamic bridging during flow of stable colloidal particles within cylindrical pores. J Fluid Mech 385:129–156

Sharp KV, Adrian RJ (2005) On flow-blocking particle structures in microtubes. Microfluid Nanofluid 1(4):376–380

Stamm MT, Gudipaty T, Rush C, Jiang L, Zohar Y (2011) Particle aggregation rate in a microchannel due to a dilute suspension flow. Microfluid Nanofluid 11:395–403

Verwey EJW, Overbeek JTG (1948) Theory of the stability of lyophobic colloids. Courier Dover Publications

Wiegmann A, Rief S, Latz A, Iliev O (2009) Toward predicting filtration and separation : progress and Challenges. Filtech, Wiesbaden, Deutschland 1:48–63

Wyss HM, Blair DL, Morris JF, Stone HA, Weitz DA (2006) Mechanism for clogging of microchannels. Phys Rev E 74:061402

Acknowledgments

The authors would like to thank Dr. Andréas Wiegmann for the helpful discussions on GeoDict software and Dr. Aurélie Marty for her help in the experimentation part. Dr. Paul Duru is thanked for his help in the conception and the elaboration of microseparators. This work was funded by Suez Environnement group.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bacchin, P., Derekx, Q., Veyret, D. et al. Clogging of microporous channels networks: role of connectivity and tortuosity. Microfluid Nanofluid 17, 85–96 (2014). https://doi.org/10.1007/s10404-013-1288-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-013-1288-4