Abstract

Studies related to energy use efficiency in Turkey and the World is one of the most important indicators for determining energy efficiency in agricultural production. In this study, previous studies related to the energy use efficiency of agricultural production in fruit areas in Turkey and the world have been included. Studies related to fruit production have been assorted and then the calculations of the indicators of energy input, energy output, energy use efficiency, energy productivity, specific energy and net energy, used to determine energy use efficiency in production areas, have been placed into tables. According to the study results, among energy inputs in fruit production chemical fertilizer consumption and fuel consumption are the most commonly used inputs. Summarized and tabulated as such, these indicators will serve as a collective resource for comparison and assessment purposes during studies to be conducted on energy use efficiency in fruit production.

Similar content being viewed by others

Introduction

Energy has a key role in economic and social progress but there is a general lack of rural energy development policies that focus on agriculture (FAO 2008; Rafiee et al. 2010). Efficient use of energy is one of the main demands of sustainable agriculture. Energy use in agriculture has become more intense in response to increasing population, restricted supply of arable land and a desire for higher standards of life. Continuous demand in increasing food production resulted in intense use of chemical fertilizers, pesticides, agricultural machinery, electricity and other natural resources. Efficient use of energy in agriculture will minimize environmental problems, prevent destruction of natural resources and advance sustainable agriculture as an economical production system (Erdal et al. 2007; Omer 2007; Rafiee et al. 2010). The energy balance is defined as the difference between gross energy of useful products divided by non-renewable energies used to produce them (Risoud 2000; Azizi and Heidari 2013). Imposing energy balances could lead to more productive and environmentally friendly crop production (Moreno et al. 2011; Azizi and Heidari 2013).

Today’s agricultural production relies heavily on the consumption of non-renewable fossil fuels. Consumption of fossil energy results in direct negative environmental effects through deliver of CO2 and other combustion gases. Indirectly, there have been positive effects: increased yields and reduced risk. Yet, large amounts of cheap fossil energy have indirect negative impacts on the environment like less various natures through the condensation of agricultural practices (Refsgaard et al. 1998; Gündoğmuş 2006). Effective energy use in agriculture is one of the conditions for sustainable agricultural production, since it ensures financial savings, fossil fuels preservation and air pollution reduction (Pervanchon et al. 2002; Gündoğmuş 2006). The energy input-output analysis are usually made to determine the energy use efficiency and environmental aspects. This analysis will determine how efficient the energy is used (Rafiee et al. 2010).

Different researches have been done on energy use efficiency of fruit products in the World. In this study, twenty fruit products in the literature were evaluated. For example, studies have been done on energy use efficiency analysis of almond (Beigi et al. 2016), apricot (Esengün et al. 2007), apple (Rafiee et al. 2010), banana (Akçaöz 2011), cherry (Kızılaslan 2009), grape (Koçtürk and Engindeniz 2009), kiwifruit (Mohammadi et al. 2010), lemon (Ozkan et al. 2004), mandarin (Ozkan et al. 2004), mulberry (Gökdoğan et al. 2017), nectarin (Qasemi-Kordkheili et al. 2013), orange (Ozkan et al. 2004), peach (Göktolga et al. 2006), pear (Tabatabaie et al. 2013), plum (Baran et al. 2017a), pomegranate (Canakcı 2010), quince (Gündoğmuş 2013), strawberry (Banaeian et al. 2011), sweet cherry (Demircan et al. 2006) and walnut (Baran et al. 2017b). Although many experimental studies have been done on energy use efficiency analysis in fruit field but there is no study on collective (tabulated) energy efficiency evaluation study on fruit production. Energy use efficiency indicators will serve as a collective resource for comparison and assessment purposes during studies to be conducted on energy use efficiency in fruit production.

Materials and Method

In order to evaluate the energy use efficiency of these fruit data have been done literature search. In this study, twenty fruit products have been evaluated in the literature of the World. In fruit energy use efficiency studies, human labour energy, animal labour energy, machinery energy, diesel fuel energy, chemical fertilizers energy, pesticides energy, irrigation energy, farmyard manure energy, organic fertilizers energy and electricity energy have been contained as inputs. Fruit has been contained as output. Total energy in area unit (ha) composed each total of input energy and energy equivalents of all inputs in MJ unit. In order to compute the energy input-output in fruit production, energy use efficiency (energy output/energy input), energy productivity (yield output/energy input), specific energy (energy input/yield output) and net energy (energy output – energy input), in the form of direct and direct, as well as renewable and non-renewable energy have been computed by researchers. In this study, data of these studies have been evaluated, commented and tabulated (Table 1, 2 and 3).

Results and Discussion

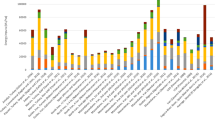

In fruit studies, yield, energy input, energy output, energy use efficiency, energy productivity, specific energy and net energy values have been tabulated (Table 1). It can be seen from these Table 1 that the first, second and third highest energy inputs (MJ ha−1) in fruit studies are strawberry (805,376.30 MJ ha−1), pear (172,608.43 MJ ha−1) and lemon (62,977.87 MJ ha−1), respectively. If the average values are analysed by referring to Table 1, it can be seen that highest yield (kg ha−1) in fruit production are strawberry (64,153.33 kg ha−1), banana 51,592.04 (MJ ha−1) and pear 46,390.59 (MJ ha−1), respectively. The first, second and third highest energy use efficiency in fruit studies are grape (8.64), mulberry (5.62) and pomegranate (2.87), respectively. Grape, mulberry and pomegranate are the most profitable production in terms of energy use efficiency.

It can be seen from these Table 1 that the first, second and third highest energy outputs (MJ ha−1) in fruit studies are strawberry (121,891.33 MJ ha−1), banana (98,024.88 MJ ha−1) and pear (88,142.13 MJ ha−1), respectively. It can be seen from these Table 1 that the first, second and third highest net energy (MJ ha−1) in fruit studies are grape (286,422 MJ ha−1), pomegranate (60,836 MJ ha−1) and banana (46,464.83 MJ ha−1), respectively.

In this study, some energy inputs have been considered, for example; farmyard manure energy (renewable energy), chemical fertilizers, machinery and diesel fuel energy (non-renewable energy) have been tabulated (Table 2). It can be seen from these Table 2 that the first, second and third highest chemical fertilizers energy inputs (%) in fruit studies are walnut (74.40%), pomegranate (57.40%) and quince (52.86%), respectively. The first, second and third highest diesel fuel energy inputs (%) in studies are strawberry (78.30%), grape (33.04%) and orange (31.18%), respectively. Machinery energy consumption in studies is banana (20.58%), plum (12.27%) and grape (10.52%), respectively. In this study, farmyard manure energy consumption (%) is banana (21.78%), apple (17.65%) and apricot (16.03%), respectively.

The distribution of inputs has used for the production of fruit production, in accordance to direct, indirect, renewable and non-renewable energy groups have been given in Table 3. It can be seen from these Table 3 that the first, second and third highest non-renewable energy inputs (%) in fruit studies are grape (97.03%), mandarin (96.08%) and lemon (95.91%), respectively. The highest renewable energy (%) in studies is mulberry production. The consumed total energy input in mulberry production could be classified as (88.10%) renewable and (11.90%) non-renewable. Renewable energy ratio is high, because; mullberry production is organic production. If energy use efficiency is to be increased, farmyard manure and organic fertilizer should be used instead of chemical fertilizers.

When the results have been evaluated, generally, fruit production are profitable production in terms of energy use efficiency (average energy use efficiency: 1.76). Non-renewable energy use is very high in fruit production. Optimization is an important appliance to maximize the amount of productivity which can significantly affect the energy consumption and production costs. Optimization of energy use in agricultural systems is carried out in two ways: an increase in productivity with the existing level of energy inputs or conserving energy without affecting the productivity. Energy management becomes more important when the energy required should be economical, sustainable and productive (Gündoğmuş 2013). According to Demircan et al. (2006), “suitable tractor selection and management of machinery to reduce direct use of diesel fuel (Işık and Sabancı 1991) and precise fertilization management, knowing the correct amount and frequency of fertilization (especially nitrogen) (Kitani 1999) have needed to save non-renewable energy sources without impairing the yield or profitability, in order to improve the energy usage efficiency of sweet cherry production”. For decrease of inputs (machinery and diesel fuel) of fruit production, these advices may perform for fruit production. Additionally, farmyard manure and organic fertilizer should be used instead of chemical fertilizers to reduce non-renewable energy.

References

Akçaöz H (2011) Analysis of energy use for banana production: a case study from Turkey. Afr J Agric Res 6(25):5618–5624

Azizi A, Heidari S (2013) A comparative study on energy balance and economical indices in irrigated and dry land barley production systems. Int J Environ Sci Technol (Tehran) 10:1019–1028

Banaeian N, Omid M, Ahmadi H (2011) Energy and economic analysis of greenhouse strawberry production in Tehran province of Iran. Energy Convers Manag 52:1020–1025

Baran MF, Oğuz HI, Gökdoğan O (2017a) Determiniation of energy input-output analysis in plum (Prunus domestica L.) production. Erwerb Obstbau. https://doi.org/10.1007/s10341-017-0332-z

Baran MF, Gökdoğan O, Oğuz HI (2017b) Determining the energy usage efficiency of walnut (Juglans regia L.) cultivation in Turkey. Erwerb Obstbau 59:77–82

Beigi M, Torki-Harchegani M, Ghanbarian D (2016) Energy use efficiency and economical analysis of almond production: a case study in Chaharmahal-Va-Bakhtiari province, Iran. Energy Effic 9:745–754

Canakcı M (2010) Energy use pattern and economic analyses of pomegranate cultivation in Turkey. Afr J Agric Res 5(7):491–499

Demircan V, Ekinci K, Keener HM, Akbolat D, Ekinci C (2006) Energy and economic analysis of sweet cherry production in Turkey: a case study from Isparta province. Energy Convers Manag 47:1761–1769

Erdal G, Esengün K, Erdal H, Gündüz O (2007) Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 32:35–41

Esengün K, Gunduz O, Erdal G (2007) Input–output energy analysis in dry apricot production of Turkey. Energy Convers Manag 48:592–598

FAO (2008) Food and agricultural organization (www.fao.org)

Gökdoğan O, Oğuz HI, Baran MF (2017) Energy input-output analysis in organic mulberry (Morus spp.) production in Turkey: a case study Adıyaman-Tut Region. Erwerb Obstbau. https://doi.org/10.1007/s10341-017-0333-y

Göktolga ZG, Gözener B, Karkacıer O (2006) Seftali üretiminde enerji kullanımı: Tokat ili örneği. J Agric Fac Gaziosmanpasa Univ 23(2):39–44 (in Turkish. Gaziosmanpaşa Üniversitesi Ziraat Fakültesi Dergisi)

Gündoğmuş E (2006) Energy use on organic farming: a comparative analysis on organic versus conventional apricot production on small holdings in Turkey. Energy Convers Manag 47:3351–3359

Gündoğmuş E (2013) Energy use patterns and econometric models of quince production. Actual Probl Econ 5(143):236–246

Işık A, Sabancı A (1991) A research on determining basic management data and developing optimum selection models of farm machinery and power for the mechanization planning in the irrigated farming of the Cukurova region. Turk J Agric For 15:899–920

Kitani O (1999) Energy for biological systems. In: The International Commission of Agricultural Engineering (ed) CIGR Handbook of Agricultural Engineering: Energy and biomass engineering, vol 5. American Society of Agricultural Engineers, St. Joseph, USA, pp 13–42

Kızılaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358

Koçtürk OM, Engindeniz S (2009) Energy and cost analysis of sultana grape growing: a case study of Manisa, west Turkey. Afr J Agric Res 4(10):938–943

Mohammadi A, Rafiee S, Mohtasebi SS, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075

Moreno MM, Lacasta C, Meco R, Mor C (2011) Rainfed crop energy balance of different farming systems and crop rotations in a semi-arid environment: results of a long-term trial. Soil Tillage Res 114:18–27

Omer AM (2007) Renewable energy resources for electricity generation in Sudan. Renew Sustain Energy Rev 11:1481–1497

Ozkan B, Akçaöz H, Karadeniz F (2004) Energy requirement and economic analysis of citrus production in Turkey. Energy Convers Manag 45:1821–1830

Pervanchon F, Bockstaller C, Girardin P (2002) Assessment of energy use in arable farming systems by means of an agro ecological indicator: the energy indicator. Agric Syst 72:149–172

Qasemi-Kordkheili P, Kazemi N, Hemmati A, Taki M (2013) Energy consumption, input-output relationship and economic analysis for nectarine production in Sari region, Iran. Int J Agric Crop Sci 5–2:125–131

Rafiee S, Aval SHM, Mohammadi A (2010) Modelling and sensitivity analysis of energy inputs for apple production in Iran. Energy 35:3301–3306

Refsgaard K, Halberg N, Kristensen ES (1998) Energy utilization in crop and dairy production in organic and conventional livestock production systems. Agric Syst 57(4):599–630

Risoud B (2000) Energy efficiency of various French farming systems: questions and sustainability. International Conference “Sustainable energy: new challenges for agriculture and implications for land use”, May 18–20 (Organized by Wageningen University, Netherlands)

Tabatabaie SMH, Rafiee S, Keyhani A, Heidari MD (2013) Energy use pattern and sensitivity analysis of energy inputs and input costs for pear production in Iran. Renew Energy 51:7–12

Acknowledgements

This study has been submitted as oral abstract in International Conference on Agriculture, Forest, Food Sciences and Technologies (ICAFOF 2017) 15–17 May 2017, Cappadocia–Turkey.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

O. Gökdoğan, O. Erdoğan, H.I. Oğuz and M.F. Baran declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Gökdoğan, O., Erdoğan, O., Oğuz, H.I. et al. Studies of Energy Use Efficiency on Fruit Production. Erwerbs-Obstbau 61, 47–51 (2019). https://doi.org/10.1007/s10341-018-0392-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-018-0392-8