Abstract

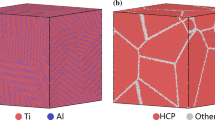

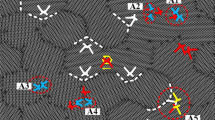

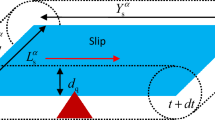

Mechanical behavior and microstructure evolution of polycrystalline copper with nano-twins were investigated in the present work by finite element simulations. The fracture of grain boundaries are described by a cohesive interface constitutive model based on the strain gradient plasticity theory. A systematic study of the strength and ductility for different grain sizes and twin lamellae distributions is performed. The results show that the material strength and ductility strongly depend on the grain size and the distribution of twin lamellae microstructures in the polycrystalline copper.

Similar content being viewed by others

References

Lu, L., Shen, Y.F., Chen, X.H., Qian, L. and Lu, K., Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304: 422–426.

Shen, Y.F., Lu, L., Lu, Q.H., Jin, Z.H. and Lu, K., Tensile properties of copper with nano-scale twins. Scripta Materialia, 2005, 52: 989–994.

Ma, E., Wang, Y.M., Lu, Q.H., Sui, M.L., Lu, L. and Lu, K., Strain hardening and large tensile elongation in ultrahigh-strength nano-twinned copper. Applied Physics Letters, 2004, 85: 4932–4934.

Lu, L., Schwaiter, R., Shan, Z.W., Dao, M., Lu, K. and Suresh, S., Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Materialia, 2005, 53: 2169–2179.

Jin, Z.H., Gumbsch, P., Ma, E., Albe, K., Lu, K., Hahn, H. and Gleiter, H., The interaction mechanism of screw dislocations with coherent twin boundaries in different face-centred cubic metals. Scripta Materialia, 2006, 54: 1163–1168.

Zhu, T., Li, J., Samanta, A., Kim, H.G. and Suresh, S., Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proceedings of the National Academy of Sciences, 2007, 104: 3031–3036.

Dao, M., Lu, L., Shen, Y.F. and Suresh, S., Strength, strain-rate sensitivity and ductility of copper with nanoscale twins. Acta Materialia, 2007, 54: 5421–5432.

Schwaiger, R., Moser, B., Dao, M., Chollacoop, N. and Suresh, S., Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Materialia, 2003, 51: 5159–5172.

Kumar, K.S., Van Swygenhoven, H. and Suresh, S., Mechanical behavior of nano-crystalline metals and alloys. Acta Materialia, 2003, 51: 5743–5774.

Kumar, K.S., Suresh, S., Chisholm, M.F., Horton, J.A. and Wang, P., Deformation of electro- deposited nanocrystalline nickel. Acta Materialia, 2003, 51: 387–405.

Han, C.S., Gao, H., Huang, Y. and Nix, W.D., Mechanism-based strain gradient crystal plasticity—I. Theory. Journal of the Mechanics and Physics of Solids, 2005, 53: 1188–1203.

Han, C.S., Gao, H., Huang, Y. and Nix, W.D., Mechanism-based strain gradient crystal plasticity—II. Analysis. Journal of the Mechanics and Physics of Solids, 2005, 53: 1204–1222.

Huang, Y., Qu, S., Hwang, K.C., Li, M. and Gao, H., A conventional theory of mechanism based strain gradient plasticity. International Journal of Plasticity, 2004, 20: 753–782.

Qu, S., Huang, Y., Pharr, G.M. and Hwang, K.C., The indentation size effect in the spherical indentation of iridium: A study via the conventional theory of mechanism-based strain gradient plasticity. International Journal of Plasticity, 2006, 22: 1265–1286.

Gao, H., Huang, Y., Nix, W.D. and Hutchinson, J.W., Mechanism-based strain gradient plasticity—I. Theory. Journal of the Mechanics and Physics of Solids, 1999, 47: 1239–1263.

Qu, S., Huang, Y., Jiang, H., Liu, C., Wu, P.D. and Hwang, K.C., Fracture analysis in the conventional theory of mechanism-based strain gradient (CMSG) plasticity. International Journal of Fracture, 2004, 129: 199–220.

Hibbit, Karlsson and Sorensen Inc. ABAQUS/Standard User’s Manual Version 6.2, 2001.

Barenblatt, G.I., The formation of equilibrium cracks during brittle fracture: general ideas and hypotheses, axially symmetric cracks. Applied Mathematics and Mechanics, 1959, 23: 622–636.

Dugdale, D.S., Yielding of steel sheets containing slits. Journal of the Mechanics and Physics of Solids, 1960, 8: 100–104.

Needleman, A., An analysis of t Tensile decohesion along an interface. Journal of the Mechanics and Physics of Solids, 1990, 38: 289–324.

Tvergaard, V. and Hutchinson, J.W., The relation between crack growth resistance and fracture process parameters in elastic-plastic solids. Journal of the Mechanics and Physics of Solids, 1992, 40: 1377–1397.

Qu, S., Siegmund, T., Huang, Y., Wu, P.D., Zhang, F. and Hwang, K.C., A study of particle size effect and interface fracture in aluminum alloy composite via an extended conventional theory of mechanism-based strain-gradient plasticity. Composites Science and Technology, 2005, 65: 1244–1253.

Warner, D.H. and Molinari, J.F., Micromechanical finite element modeling of compressive fracture in confined alumina ceramic. Acta Materialia, 2006, 54: 5135–5145.

VanSwygenhoven, H. and Derlet, P.M., Grain-boundary sliding in nanocrystalline fcc metals. Physical Review B, 2001, 64: 1–9.

Conrad, H. and Narayan, J., On the grain size softening in nanocrystalline materials. Scripta Materialia, 2000, 42: 1025–1030.

Van der Sluis, O., Schreurs, P.J.G. and Meijer, H.E.H., Homogenization of structured elasto- viscoplastic solids at finite strains. Mechanics of Materials, 2001, 33: 499–522.

Chen, X.H. and Lu, L., Work hardening of ultrafine-grained copper with nanoscale twins. Scripta Materialia, 2007, 57: 133–136.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (Nos. 10432050, 10428207, 10672163 and 10721202) and by the Chinese Academy of Science through Grant KJCX-YW-M04.

Rights and permissions

About this article

Cite this article

Wu, B., Wei, Y. Simulations of Mechanical Behavior of Polycrystalline Copper with Nano-Twins. Acta Mech. Solida Sin. 21, 189–197 (2008). https://doi.org/10.1007/s10338-008-0822-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-008-0822-5