Abstract

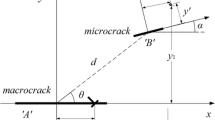

The effects of dislocation configuration, crack blunting and free surfaces on the triggering load of dislocation sources in the vicinity of a crack or a wedge tip subjected to a tensile load in the far field are investigated. An appropriate triggering criterion for dislocation sources is proposed by considering the configurational forces acting on each dislocation. The triggering behaviors of dislocation sources near the tips of a crack and a wedge are compared. It is also found that the blunting of crack tip and the presence of free surfaces near the crack or the wedge have considerable influences on the triggering load of dislocation sources. This study might be of significance to gaining a deeper understanding of the brittle-to-ductile transition of materials.

Similar content being viewed by others

References

Rice J.R. and Thomson R., Ductile versus brittle behavior of crystals. Phil. Mag., 1974, 29: 73–97.

Hirsch P.B., Roberts S.G. and Samuels J., The brittle-ductile transition in silicon — II. Interpretation. Proc. R. Soc. London Ser. A, 1989, 421: 25–53.

Gumbsch P., Riedle J., Hartmaier A. and Fischmeister H.F., Controlling factors for the brittle-to-ductile transition in tungsten single crystals. Science, 1998, 282: 1293–1295.

Lu Z.X., Yu S.W. and Feng X.Q., A triggering criterion of dislocation sources under mode-I singular stresses. Int. J. Fracture, 2004, 126: 281–286.

Rice J.R., Dislocation nucleation from a crack tip: an analysis based on the Peierls concept. J. Mech. Phys. Solids, 1992, 40: 239–271.

Weertman J., Crack tip blunting by dislocation pair creation and separation. Phil. Mag. A., 1981, 43: 1103–1123.

Qian C.F., Li K.J., Chen H. and Li J.C.M., Interaction between edge dislocations around the tip of a crack. Mech. Mater., 1996, 24: 221–227.

Beltz G.E., Lipkin D.M. and Fischer L.L., Role of crack blunting in ductile versus brittle response of crystalline materials. Phys. Rev. Lett., 1999, 82: 4468–4471.

Huang M.X. and Li Z.H., Dislocation emission criterion from a blunt crack tip. J. Mech. Phys. Solids, 2004, 52: 1991–2003.

Blanckenhagen B., Gumbsch P. and Arzt E., Dislocation sources and the flow stress of polycrystalline thin metal films. Phil. Mag. Lett., 2003, 83: 1–8.

Wang S.D. and Lee S., Screw dislocations near a subsurface crack. J. Phys. D: Appl. Phys., 1998, 31: 602–608.

Yang F.Q. and Li J.C.M., Dislocation model of a subsurface crack. J. Appl. Phys., 1997, 82: 4816–4822.

Lakshmanan V. and Li J.C.M., Edge dislocations emitted along inclined planes from a Mode I crack. Mater. Sci. Eng., 1988, 104: 95–104.

Creager M. and Paris P.C., Elastic field equations for blunt cracks with reference to stress corrosion cracking. Int. J. Fracture, 1967, 3: 247–251.

Author information

Authors and Affiliations

Additional information

Project supported by the National Nature Science Foundation of China (Nos. 10572067, 10525210 and 10121202).

Rights and permissions

About this article

Cite this article

Lu, Z., Wang, X., Yu, S. et al. Effects of dislocation configuration, crack blunting and free surfaces on the triggering load of dislocation sources. Acta Mech. Solida Sin. 20, 103–109 (2007). https://doi.org/10.1007/s10338-007-0712-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-007-0712-2