Abstract

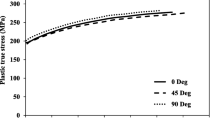

This paper presents the application of anisotropic damage theory to the study of forming limit diagram of Al2024T3 aluminum alloy sheet. In the prediction of limiting strains of the aluminum sheet structure, a finite element cell model has been constructed. The cell model consists of two phases, the aluminum alloy matrix and the intermetallic cluster. The material behavior of the aluminum alloy matrix is described with a fully coupled elasto-plastic damage constitutive equation. The intermetallic cluster is assumed to be elastic and brittle. By varying the stretching ratio, the limiting strains of the sheet under biaxial stretching have been predicted by using the necking criterion proposed. The prediction is in good agreement with the experimental findings. Moreover, the finite element cell model can provide information for understanding the microscopic damage mechanism of the aluminum alloy. Over-estimation of the limit strains may result if the effect of material damage is ignored in the sheet metal forming study.

Similar content being viewed by others

References

Marciniak, Z. and Kuczynski, K., Limit strains in the processes of stretch-forming sheet metal, Inter J Mech Sci, Vol.9, 1967, 609–620.

Azrin, M. and Backofen, W.A., The deformation and failure of a biaxially stretched sheet, Metallurgical Trans, Vol.1, 1970, 2857–2865.

Venter, R., Johnson, W. and de Malherbe, M.C., The limit strains of inhomogeneous sheet metal in biaxial tension, Inter J Mech Sci, Vol.13, 1971, 299–308.

Sowerby, R. and Duncan, J.L., Failure in sheet metal in biaxial tension, Inter J Mech Sci, Vol.13, 1971, 217–229.

Parmar, A. and Mellor, P.B., Predictions of limit strains in sheet metal using a more general yield criterion, Inter J Mech Sci, Vol.20, 1978, 385–391.

Needleman, A. and Triantafyllidis, N., Void growth and local necking in biaxially stretched sheets, Tran ASME, J Engng Mater Tech, Vol.100, 1978, 164–9.

Gurson, A.L., Continuum theory of ductile rupture by void nucleation and growth: Part I — Yield criteria and flow rules for porous ductile media, Trans ASME, J Engng Mater Tech, Vol.99, 1977, 2–15.

Padwal, S.B. and Chaturvedi, R.C., Prediction of forming limits using Hosford’s modified yield criterion, Inter J Mech Sci, Vol.34, 1992, 541–547.

Hosford, W.F., Comments on anisotropic yield criteria, Inter J Mech Sci, Vol.27, 1985, 423–427.

van Minh, H., Sowerby, R. and Duncan, J.L., Probabilistic model of limit strains in sheet metal, Inter J Mech Sci, Vol.17, 1975, 339–349.

Yamaguchi, K. and Mellor, P.B., Thickness and grain size dependence of limit strains in sheet metal stretching, Inter J Mech Sciz, Vol.18, 1976, 85–90.

Date, P.P. and Padmanabhan, K.A., On the prediction of the forming-limit diagram of sheet metals, Inter J Mech Sci, Vol.34, 1992, 363–374.

Chow, C.L. and Wang, J., An anisotropic theory of elasticity for continuum damage mechanics, Inter J Fract, Vol.33, 1987, 3–16.

Chow, C.L. and Wang, J., An anisotropic theory of continuum damage mechanics for ductile fracture, Engng Fract Mech, Vol.27, 1987, 547–558.

Chow, C.L. and Wang, J., An anisotropic continuum damage theory and its application to ductile crack initiation, Damage Mech Compos ASME AD, Vol.12, 1987, 1–10.

Chow, C.L. and Wang, J., Ductile fracture characterization with an anisotropic continuum damage theory, Engng Fract Mech, Vol.30, 1988, 547–563.

Lee, W.B., Tai, W.H. and Tang, C.Y., Damage evolution and forming limit prediction of an Al2024-T3 aluminum alloy, J Mate Process Tech, Vol.63, 1997, 100–104.

Tang, C.Y., Shen, W. and Lee, T.C., A damage-base criterion for fracture preditiion in metal forming processes: a case study in Al 2024T3 sheet, J Mater Process Tech, Vol.89, 1999, 79–83.

Tang, C.Y., Chow, C.L., Shen, W. and Tai, W.H., Development of a damage-based criterion for ductile fracture prediction in sheet metal forming, J Mater Process Tech, Vol.91, 1999, 270–277.

Tang, C.Y. and Tai, W.H., Material damage and forming limits of textured sheet metals, J Mater Process Tech, Vol.99, 2000, 135–140.

Tang, C.Y., Modelling of craze damage in polymeric materials: a case study in polystyrene and high impact polystyrene. Ph.D. Thesis, The Hong Kong Polytechnic University, 1995.

Tang, C.Y., Shen, W., Fung, L.C. and Lee, T.C., Second-order continuity tensor and stiffness degradation of aluminum alloy 2024T3 under large strain at room temperature, Inter J Mech Sci, Vol.42, 2000, 87–105.

Tang, C.Y., Lee, T.C. and Rao, B., An experimental study of shear damage using in-situ single shear test, Inter J Damage Mech, Vol.11, 2002, 335–353.

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the Research Committee of The Hong Kong Polytechnic University (No.G-YX34).

Rights and permissions

About this article

Cite this article

Tang, C.Y., Fan, J. & Tsui, C.P. Prediction for forming limit of Al2024T3 sheet based on damage theory using finite element method. Acta Mech. Solida Sin. 19, 174–180 (2006). https://doi.org/10.1007/s10338-006-0621-9

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-006-0621-9