Abstract

Eating safe and healthy food is a rising consumer awareness. Oxygen-sensitive foods can now be better protected using oxygen scavenging films, an emerging technology that extends the shelf life and maintains the quality and freshness of food products. The use of oxygen-absorbing materials in packaging is a current trend in active packaging, especially in food packaging. Some oxygen scavenging films have shown excellent oxygen absorbance and become commercial successes. Here, we review oxygen scavenging films used in food packaging, such as novel natural oxygen scavenging agents and active barrier films.

Similar content being viewed by others

Introduction

In recent years, consumers have become increasingly conscious about their health and hence are willing to pay a higher price for healthy, fresh food. Consequently, the consumer food industries have begun to apply advanced technologies to preserve the freshness and nutrients of food (Singh et al. 2017a, b; Irkin and Esmer 2015; Gaikwad et al. 2013). The causes of food spoilage include microbial growth, chemical interactions between the components of a foodstuff, and the action of enzymes present in the products (Singh et al. 2016a, b, c; Gaikwad et al. 2017a, b Choi et al. 2016). Some of these causes stem from the presence of oxygen around the product. Oxygen can turn fats rancid, cause flavor deterioration, create color changes, encourage the growth of mold and aerobic bacteria, and deplete nutritional value (Gaikwad et al. 2016).

Using oxygen scavenging or absorbing agents offers several benefits, such as inhibiting the formation of microbial growth, maintaining the quality of lipid-containing foods (preventing rancidity), avoiding discoloration, and avoiding oxidation (Johnson and Decker 2015; Nayik and Muzaffar 2014). Oxygen scavengers are widely used in this food industry, as they extend the shelf life of products from 3–4 to 14 days or more (Gaikwad and Lee 2017; Singh et al. 2016a, b, c). Currently, commercial oxygen scavengers take many forms, including sachets, films (directly in the package), and labels. However, incorporating scavengers directly into packaging materials has better consumer acceptance than using sachets. The oxygen scavengers market is expected to reach USD 2.41 Billion by 2022, at a compound annual growth rate (CAGR) of 5.1% from 2017 to 2022. Mitsubishi Gas Chemical Company (Japan), BASF SE (Germany), Ecolab Inc. (USA), Clariant Ltd. (Switzerland), and Kemira OYJ (Finland) are the leading players operating in the oxygen scavengers market (Anonymous 2017a, b). The increasing demand for high-quality packaged food is one the major drivers for the growth of oxygen scavengers market. Factors such as increasing disposable income and changing lifestyle of the middle-class population in emerging countries are expected to fuel the demand for packaged food. This increase in demand is consequently expected to drive the growth of the oxygen scavengers market in the coming years. The growing awareness regarding the reduction of food wastage and the increased demand for advanced packaging among consumers are expected to further aid the growth of the market during the forecast period. Oxygen scavenging films extend the shelf life of foods while maintaining their nutritional quality and preventing discoloration, microbial spoilage, rancidity, and organoleptic deterioration, thereby ensuring food safety (Cichello 2015).

Polymers have advantages over materials such as glass and metal, so the use of oxygen scavenging polymers in food packaging has increased, along with research into incorporating oxygen scavenging substances into polymers as shown in Fig. 1 The large variety of plastic materials and the different compositions available allow companies to adopt a packaging solution and design most convenient to the specific needs of each product.

The permeation of gases through the packaging material is a still big issue preventing the use of polymers in food packaging applications. Plastic is the preferred packaging material; however, plastic materials do not possess good gas barrier properties, particularly to oxygen, compared with other available materials such as glass or metal (Marsh and Bugusu 2007). The polymers used in food packaging applications should provide a sufficient barrier to gas and moisture; otherwise, the quality and the shelf life of packaged food will be directly affected. Most polymeric films used in oxygen scavenging use low-permeability plastics (less than 2.28 × 10−15 m3/m2 s Pa) made from polyethylene (PE), low-density (LD) PE, very low-density polyethylene, ultra-low-density PE, high-density (HD) PE, and polyethylene terephthalate (PET) (Ahn et al. 2016; Busolo and Lagaron 2012; Matche et al. 2011; Shin et al. 2011). In addition, polylactic acid (PLA) has attractive properties, for example, a high flavor and grease resistance, high clarity, and excellent printability, making it the most popular biodegradable polymer that can be manufactured using conventional processing technologies (Jamshidian et al. 2012). However, a major drawback of PLA for food packaging is its relatively high permeability to gases and vapors, which limits its application to short-lifespan packaged foods. The use of oxygen scavengers in packaging films is a possible solution to such issues.

The aim of this review is to provide an overview of recent studies on oxygen scavenging films and look at future trends and challenges. We first discuss the major types of oxygen scavenging agents, their activation, major polymeric materials, and active barrier layers. Then, we provide an overview of issues such as retort shock, applications, future trends, and challenges for oxygen scavenging films.

Oxygen scavenging agents

In principle, any oxidizing substrate, organic or inorganic, can be an oxygen scavenger (Sun 2016). Price, safety, and the rate and capacity of reaction with oxygen restrict the range of candidate agents in food packaging. In recent years, some novel nonmetallic agents have received considerable attention, including organic and polymer-based agents. Some potential oxygen scavenging agents for food packaging applications are listed and classified in Table 1. Although most commercial oxygen scavenging films use iron (Fe)-based agents for oxygen-sensitive food, the oxygen scavenging film industry has become increasingly interested in the development and application of novel scavenging agents.

Metallic scavengers

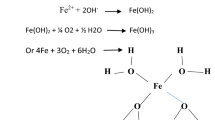

Metallic scavengers are the largest segment of the market and have been used commercially for many years (Herbert and Schiraldi 2014). Iron-based oxygen scavengers are the most widely used agents for the preservation of packaged foods. The commercial success of these systems arises from their high efficiency, low price, and rapid rate of oxidation. Yildirim et al. (2015) studied palladium, another metallic oxygen scavenging compound that had deposited into films in layers using the vacuum method to remove residual oxygen in food packages after modified atmosphere packaging (MAP). The oxygen scavenging rate of the coated film depended strongly on the thickness of the palladium deposit. The authors found that PET, aluminum oxide-coated PET, oriented polypropylene (PP), and PLA are the most suitable substrates for palladium-based oxygen scavengers. In addition, an intermediate SiO x layer between the substrate and the palladium layer substantially increased the oxygen scavenging rate for all packaging films. In addition, they found that the optimal palladium layer thickness was between 0.7 and 3.4 nm. Matche et al. (2011) developed a modified linear LDPE film by incorporating zinc, iron, or ascorbic acid. The developed films were characterized for their physical and mechanical properties, and the oxygen scavenging properties were studied using the shelf life of buns and bread as a metric. The physical properties were affected by the iron-based scavenger in terms of mechanical and barrier properties; however, the bread packed in the oxygen scavenging films fostered the growth of a minute quantity of microbes, although under the prescribed limit. Di Maio et al. (2014) investigated a three-layer oxygen scavenging film with PET containing iron-based agents for the packaging of freshly cut apples. After 15 days of storage at 8 °C, the freshly cut samples compared well to a control sample. Films based on oxidizable transition metals, for example, copper, zinc, magnesium, manganese, aluminum, palladium, or titanium, are also known. Photocatalytic oxygen scavenging films have also been developed by the incorporation of nanocrystalline titania particles (Mills et al. 2006).

Some disadvantages of iron-based scavenging films include potential metal contamination, inadvertently setting off inline metal detectors, and inhibiting heating in microwave ovens. Additionally, another problem facing iron-based scavenging films is the temperature-reliant nature of iron oxidation, which can cause major premature oxygen scavenging action of self-reactive films at high temperatures, thus reducing the scavenging capacity or slowing scavenging rates at low temperatures and creating technical difficulties for food packaging applications.

Organic scavengers

Recently, academic and industrial research has focused on the production and application of organic-based oxygen scavengers for oxygen-absorbing films. Metallic agents have limitations regarding the metal detection process on the packaging production line; hence, researchers are focusing on the use of organic agents instead. These agents can be low-molecular weight oligomers added to polymer films or oxygen scavenging polymers in which either the backbone is designed to break apart when the polymer reacts with oxygen or the side-chains react with oxygen (Ching et al. 2000). Organic oxygen scavengers have excellent dispersion and compatibility with polymeric matrices compared to the dispersion of inorganic powders, making it possible to produce optically transparent, polymeric, active barrier films. Damaj et al. (2015) reported the use of an amino acid-based agents They added a Co(II) complex of threonine, as an oxygen scavenger, into the polymer matrix of polyvinyl alcohol (PVA). The active films were prepared by the water-casting technique, and the activation of the film depended on the relative humidity. Janjarasskul et al. (2011) developed an edible film with whey protein isolate that incorporated ascorbic acid, which has oxygen-absorbing potential. Edible oxygen scavenging films avoid the problems of both accidental consumption and the lack of recyclability of conventional oxygen scavenger systems. Another biodegradable oxygen scavenger system used 40 wt% of the natural antioxidant agent α-tocopherol loaded onto PLA microparticles by an oil-in-water emulsion-solvent evaporation method. The researchers claimed that the use of α-tocopherol did not affect the material’s biodegradability (Scarfato et al. 2015).

A patent concerning the oxygen-reducing properties of ascorbic salts has also been filed (Brody et al. 2001). The scavenging film contains a catalyst, such as a transition metal like Cu or Co, and is activated by moisture; consequently, this technology is particularly suitable for food products with high water activity. Egg-yolk protein hydrolysates were prepared by Sakanaka and Tachibana (2006) having oxygen scavenging activity arising from the enzymatic hydrolysis of fat-free egg-yolk protein, which was used to stabilize the lipid oxidation in beef and tuna homogenates. The results showed that egg-yolk protein hydrolysates suppressed the discoloration of β-carotene strongly compared to a control in β-carotene bleaching tests. At 0.5% hydrolysate content, the 2,2-diphenyl-1-picrylhydrazyl (DPPH) and hydroxyl radical scavenging activities were 74.2 and 91.7%, respectively.

Organic-based scavenging films present opportunities for creating new packaging designs with several requirements and advantages concerning consumer perception and sustainability. However, further research must focus on improvements in technical and commercial feasibility, including film O2 removal efficiency. Common drawbacks of these films are their relatively greater expense and lower scavenging capacity when applied to a polymer matrix (Byun et al. 2012).

Polymer-based scavengers

A new area of focus is polymer-based oxygen scavengers. They include a base polymer suitable for packaging applications that is modified with an unsaturated side chain attached to its backbone (Gauthier 2015). The list of various commercially available oxygen scavenging plastic film for food packaging applications is presented in Table 2. Polymer oxygen absorbers, such as oxidation–reduction resins and polymer–metal complexes, have been studied by various researchers. Fava et al. (2013) investigated oxygen barrier plastic materials comprising an organic polymer and an oxygen scavenger to enhance the quality and shelf life of oxygen-sensitive products for packaging applications. An active oxygen scavenger, such as a polyamide or polyolefin, can be incorporated into the backbone of a base polymer material to form an oxygen scavenging polymer that can be used in the walls of a package. The oxygen scavenging polymer can be used in a blend with other polymers or as an oxygen-absorbing layer in a multilayer container. The addition of a photoinitiator to an oxygen scavenging composition is common practice to prevent the premature oxidation of the scavenger during processing and storage. The main problem with this technology is that, during the reaction between polyunsaturated molecules and oxygen, by-products such as organic acids, aldehydes, or ketones can be generated and can affect the quality of food, including the color and the development of rancid off-flavors with very low detection thresholds that can unfavorably affect the sensorial quality and the taste of the product (Li et al. 2012). Some of these by-products are used to control the quality and shelf life of lipid-based products because they are related to rancidity (Jo et al. 2002). Although volatile off-flavors can be reduced by the use of odor absorbers (e.g., zeolites, activated carbons), it is favorable to reduce these by-products by using functional barriers that impede the migration of undesirable oxidation products, for example, the alteration of the polymer composition by adding unsaturated functional groups that can also act as oxygen scavengers. In this case, the oxidation of unsaturated hydrocarbons in a polymer matrix can act as an oxygen scavenger (Ferrari et al. 2009). The autoxidation of the polymers can be triggered by UV light in the presence of metal catalyst. The unsaturated hydrocarbons can be incorporated into the commonly used polymers, including LDPE and PET, to provide an oxygen barrier (Galdi et al. 2008).

Recently, oxygen scavenging films incorporating nanocrystalline titania (TiO2) have drawn attention (Xiao-e et al. 2004; De Azeredo 2009). These kinds of polymeric films can scavenge oxygen when exposed to UV light. Because of the light sensitivity of nanocrystalline TiO2 on the film surface, organic substances are oxidized, scavenging oxygen from the headspace and producing carbon dioxide. To achieve the required oxygen scavenging capacity, a proper supply of the active substance and UV exposure is necessary. Films containing light active TiO2 are also known to inactivate microorganisms and, hence, have the potential for use as antimicrobial packaging materials (Singh et al. 2016a, b, c).

Enzymatic scavengers

Enzyme-based oxidation is another approach to regulate the oxygen concentration in the food package. The enzyme reacts with a specific substance to scavenge any incoming oxygen. Glucose oxidase is a common oxygen scavenging enzyme. A mixture of two enzymes, glucose oxidase and catalase, have been used as oxygen scavengers in the past (Vermeiren et al. 1999). In the presence of moisture, glucose is oxidized to gluconic acid and hydrogen peroxide by glucose oxidase (Mabeck and Malliaras 2006).

There are few patents concerning the use of enzyme-based oxygen scavengers impregnated in polymeric materials for oxygen scavenging films (Labuza and Breene 1989). The most studied enzymes for use as oxygen scavengers are glucose oxidase and catalase. The glucose oxidase and catalase can be immobilized (Fig. 4d) as coatings on different polymers including polystyrene, polyethylene, and polypropylene. However, when the coated enzymes are immobilized, the surface carrying the active enzyme must be in direct contact with the food to activate the redox reaction; this restricts the application of enzyme-based films in food packaging (Brody et al. 2001). United enzyme oxygen scavenging systems are highly sensitive to changes in pH, water activity, salt content, temperature, and several other factors. Moreover, they require the addition of water and, thus, cannot be successfully used for low-moisture food products (Graf 1994).

Recently, Järnström et al. (2013) tested enzymes as high-barrier coatings for active food packaging. The results confirmed that the developed active coatings could be effectively used to delay the oxidation reactions and rancidity of packaged food, for example, fish stored at low temperature. In another study, the copper-containing enzyme laccase was also studied as a possible oxygen scavenging enzyme for packaging applications. The presence of phenolic hydroxyl groups in the laccase catalyzes the one-electron oxidation to phenolic radicals, While oxygne is reduced in the presence of water. The phenoxy radicals subsequently form quinines or polymerization products (Johansson et al. 2014). The co-immobilization of oxalate oxidase and catalase in latex for oxygen scavenging film was reported by Winestrand et al. (2013). Oxalate oxidase catalyzes the conversion of oxalic acid and oxygen to carbon dioxide and hydrogen peroxide, and the co-immobilized catalase was intended to degrade the generated H2O2. An advantage of enzyme-based scavenging film is it presents no problems for microwave applications and for metal detectors in the food production line. Enzyme-based oxygen scavenger films using glucose oxidase/catalase are available commercially (Bioka Ltd).

Natural oxygen scavenging systems

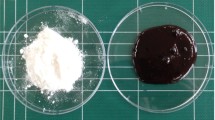

In recent years, consumers have come to prefer natural over synthetic products because of their lower perceived risk; for this reason, naturally derived oxygen scavenging systems are becoming increasingly important (Byun et al. 2012; Irkin and Esmer 2015; Gaikwad and Lee 2016). Natural oxygen scavenging interactions have been explored to improve the limitations of metal-based scavengers. Oxidation-susceptible natural substrates can be fabricated into oxygen scavengers as immobilized agents on or blended with plastic films (Janjarasskul and Suppakul 2016). Byun and Whiteside (2012) developed oxygen scavenging microparticles using an ascorbyl palmitate-β-cyclodextrin inclusion complex. The oxygen scavenging capability of the inclusion complex was matched with that of traditional iron powder at storage temperatures of 4 and 23 °C. The ascorbyl palmitate-β-cyclodextrin inclusion complex had high oxygen scavenging capacity than the iron powder at both storage temperatures. Recently, Ahn et al. (2016) developed a novel oxygen scavenging system using gallic acid and potassium carbonate that was activated by moisture and incorporated it into low density polyethylene (LDPE) films for wet food packaging applications. The oxygen scavenging reaction between gallic acid and potassium carbonate is as shown in Fig. 2. Their results indicated that the mechanical and physical properties worsened after the incorporation of the gallic acid-based oxygen scavenging system compared with those of a pure LDPE film; however, the film, which contained a 20% (w/w) oxygen scavenging system, had an oxygen scavenging capacity of 0.709 mL/g over 7 days. A natural, phenolic compound/moisture-based oxygen scavenging system prepared by Gaikwad et al. (2016) containing pyrogallol and sodium carbonate was tested for active food packaging applications. They claimed that their pyrogallol oxygen scavenging system is comparable with commercial iron-based oxygen scavenging sachets. Pyrogallol (250 mg) and sodium carbonate (250 mg) had the highest oxygen scavenging capacity (51.81 mL/g) and an oxygen scavenging rate of 6.48 mL/g. The oxygen absorption kinetics rate of pyrogallol and sodium carbonate confirmed that the agents are efficient oxygen scavengers. Byun et al. (2012) prepared an oxygen scavenging film that used natural α-tocopherol and a transition metal by casting using a film applicator (Fig. 3). Their scavenger had an oxygen scavenging capacity of 6.72 mL/g and rate of 0.11 O2/g day, indicating that their film, in the presence of moisture, is effective. Numerous antioxidant compounds (e.g., erythorbic acid, quinones, and catechol) can also be used as oxygen scavengers (Cardona et al. 2011). Other recommended natural oxygen scavengers include hydroxylamines and ketoximes. However, the possible applications of these natural scavengers in polymeric matrices and their reactive capacities per unit weight are limited.

Natural oxygen scavengers present the potential for the development of new packaging formats with numerous desirable qualities and advantages concerning both consumer perception and sustainability. The active food packing sector is expected to see increasing demand for the natural oxygen scavengers (Anonymous 2017a, b). Several trends are likely to drive the demand for natural oxygen scavengers. For example, manufacturers are planning to replace iron powder with naturally available active agents to improve the quality of food products. In addition, there are efforts to improve equipment quality and extend the shelf life of products. However, the processing of agents, cost, oxygen scavenging capacity, and safety of natural oxygen scavengers compared to iron powder are the main hurdles to the commercialization process.

Technologies for the preparation of oxygen scavenging films

Oxygen scavenging systems can be applied to packaging films in different ways, mainly by incorporation as part of multilayer films or as a physical coating/absorption onto the packaging material surface. The mechanism of activation for oxygen scavenging compounds must be considered along with the intended product application when designing an oxygen scavenging packaging film.

Coating

Oxygen scavengers can be physically adsorbed or coated onto food packaging materials so that the scavenger migrates from the package to the food to prevent oxidative reactions in the food products (Fig. 4a). Active agents can work through direct contact with foods or by generating a vapor phase that transfers the antioxidant activity to the headspace.

Various methods of application of oxygen scavenging films and the migration of oxygen scavenging compounds in each system: a the coating of the active layer onto the package surface, b incorporation of the active compound into the package polymeric matrix, c multilayer active film, and d immobilized active film

Recently, Gaikwad et al. (2017a, b) developed moisture-activated oxygen scavenging films with a pyrogallol (a natural phenolic compound) coating onto a LDPE/sodium carbonate substrate. The resultant oxygen scavenging film had a somewhat rough film surface, which resulted in higher water and oxygen permeabilities, as well as a lower tensile strength, because of the addition and agglomeration of sodium carbonate and pyrogallol. The 20% pyrogallol-coated film showed an effective oxygen scavenging capacity of 0.443 mL/g at 23 °C. Demicheva (2015) developed a polybutadiene film coated with additives as an alternative to cobalt catalysts for oxygen scavenging films. They demonstrated that the polybutadiene-based scavengers function adequately. This coating does not form the package itself, but it can reduce the barrier requirements of the package. In addition, a hydrophobically modified glucose oxidase was combined with ethylene vinyl acetate (EVA) to develop a coating for enzyme immobilization for oxygen scavenging films (Wong et al. 2017). The developed coatings effectively reduced the headspace oxygen by 2% in a closed glass vial filled with 50 vol% oxygen. This oxygen scavenging polymer coating controlled the headspace oxygen in packaged foods, maintaining the stability of the oxygen-sensitive constituents, thus protecting the colors, flavors, and nutrients in the food. An oxygen scavenging film containing nanocrystalline titania particles in an ethyl cellulose polymer was developed by Mills et al. (2006). The film has a UV-driven scavenging action. This film could scavenge oxygen at an average rate of 0.017 mL/g. The oxygen scavenging rates of the prepared films compare favorably to those associated with more traditional oxygen scavengers. The main disadvantage of these new oxygen scavenging films is the requirement of UV light to drive the scavenging process, which further increases the cost of the packaging.

Incorporation into packaging

Oxygen scavenging systems can be incorporated throughout the package (Fig. 4b). By dispersing an oxygen scavenging compound into the polymeric matrix, oxygen scavenging occurs in the package headspace and the food product and prevents oxidation accelerating factors (mainly oxygen) from permeating through the package from the external environment. As shown in Table 3, various oxygen scavenging compounds have been incorporated into different packaging materials to make active films. This approach is applicable for the preparation of active films using most kinds of scavenging compounds by either casting (Janjarasskul et al. 2011; Byun et al. 2012; Li et al. 2012) or extrusion (Ahn et al. 2016; Busolo and Lagaron 2012; Matche et al. 2011; Shin et al. 2011). Although these films are effective, they can impart an undesirable flavor to foods, especially when iron-based oxygen scavengers are used (Cruz et al. 2012). In addition, the possible migration of iron into foods can accelerate lipid-oxidative reactions. In addition, large amounts of antioxidants are needed to assure dispersion throughout the whole package, and major mass and activity losses can occur during the manufacturing process (Johnson and Decker 2015).

Multilayer active films

Multilayer packaging, in which an oxygen scavenging layer is sandwiched between inert layers (Fig. 4c), could overcome some concerns of incorporated active films, but their costs are high. For example, a ferrous Fe–based commercial oxygen scavenger layer was introduced between multiple inert layers to prepare PP/EVOH/OS/PP (EVOH, ethyl vinyl alcohol; OS, oxygen scavenger) multilayer antioxidant packaging films (Shin et al. 2011). The natural compounds α-tocopherol and quercetin were also sandwiched between two layers of EVOH, EVA, LDPE, and PP to impart antioxidant activity to these commonly used packaging polymers (Castro López et al. 2013). Recently, bio-based multilayer oxygen scavenging films that can be prepared by extrusion and laminating were developed by Pant et al. (2017) using gallic acid and sodium carbonate as the active substances incorporated in the polymer matrix. The film consists of a food contact layer (BioPE), an active layer covering the scavenger (BioPE + 15% (w/w) gallic acid and sodium carbonate), and an outer barrier layer of PLA that reduces the entrance of oxygen from the environment. The results showed an oxygen absorption capacity of 447 mg O2/g at 21 °C and 100% RH. The main application of this film is for the packaging of food products with high water activity (aw > 0.86).

A three-layer oxygen scavenging film was developed by Di Maio et al. (2015). The three layers consist of PET with a polymeric OS as the core layer and pure PET as the outer layers. The packaging tests on freshly cut, untreated apples showed that the active three-layer PET films have the potential for applications in active packaging technologies. Gibis and Rieblinger (2011) reported an oxygen scavenger multilayer film PE/AL (active layer)/EVA. The oxygen consumption of the film was influenced by the temperature. Lowering the temperature from 23 to 5 °C caused a reduction in the oxygen absorption rate of the prepared oxygen scavenger multilayer film within the first 4 days.

Polyamide-based oxygen-absorbing films consisting of a cobalt catalyst and MXD-6 nylon polymers have been commercialized as reactive oxygen scavenging barriers when incorporated into the inner layers of multilayer polymeric packaging structures, for example, as rigid PET bottles for the packaging of alcoholic beverages (MXD-6 nylon, Mitsubishi Gas Chemical Co., Inc.). Polyamides have been suggested as candidates for oxygen scavenging. However, disadvantages of this system include the delamination of the multilayer structure and potential migration of low molecular weight reaction by-products into the packaged food. In 2009, Sealed Air Corp. (USA) developed a flexible multilayer oxygen scavenging film (Cryovac® OS2000) activated by ionizing radiation. As claimed by the manufacturer, the film can reduce the oxygen concentration in the headspace from 0.4% to below 0.1% in about 8 days. To date, the applications of multilayer active films are not as widespread as those of sachets, coatings, and incorporated approaches because of the high cost and complicated manufacturing processes.

Immobilization

Surface immobilization uses common polymers such as LDPE, HDPE, PP, PET, PVA, and polystyrene. These commercially available polymers are inert and must be pretreated to introduce reactive sites to the polymer surface for the attachment of functional compounds (Fig. 4d). Several surface modification techniques have been developed for surface functionalization, including UV irradiation (Goddard and Hotchkiss 2007). UV light can be used to create functional groups or free radicals to initiate the graft polymerization of functional monomers. Short-wave UV light (UVC, 185 nm) can react with atmospheric oxygen to generate atomic oxygen and ozone, and ozone dissociates into molecular oxygen and atomic oxygen on the absorption of 254-nm UV radiation. UV irradiation has been reported to be the best surface functionalization method (Barish and Goddard 2011). Long-wave UV light (UVA, 400–315 nm) combined with photoinitiators/sensitizers (e.g., benzophenone) can convert light energy into useful chemical energy by abstracting hydrogen from the polymer substrate to generate free radicals on the surface (Odian 1991). The free radicals can then initiate the graft polymerization of functional monomers onto the polymer surfaces. Winestrand et al. (2013) developed enzyme-containing films using oxalate oxidase and catalase to scavenge oxygen. Their results suggest that the inclusion of catalase with oxalate oxidase effectively prevented the release of hydrogen peroxide. Immobilized enzymes can also be used successfully as both oxygen and oxalic-acid scavengers.

Active barriers

The use of oxygen scavengers in the form of films or sachets is not allowed in all countries; therefore, new concepts are needed to ensure excellent barrier properties in packaging materials and to incorporate oxygen scavengers into packaging films homogeneously. However, high-barrier plastic materials are available. To achieve the necessary improvements in the barrier properties of polymers, additional barrier layers or polymer multilayers must be used.

Mølgaard et al. (2014) developed a coating containing cationic nanofibrillated cellulose and polygalacturonic acid by the layer-by-layer method to achieve a high oxygen barrier and targeted release properties. The film showed low permeability to oxygen (0.033 mL (STP) mm/m2/day/atm). Beckwith et al. (2014) invented a multilayer active oxygen barrier film using EVOH with a blend of polyoctenylene and a cobalt salt in the active oxygen barrier layer made of an EVA copolymer with an ethylene content of 30–44 mol%. The oxygen scavenging rate was 0.01 mL/day/g. Sirviö et al. (2014) developed oxygen barrier films from dicarboxylic acid-functionalized nanocellulose, α-hydroxy sulfonic acid cellulose, and taurine-modified cellulose, which demonstrated oxygen permeability values of 0.12, 0.20, and 0.44 cm3 μm/(m2 day kPa), respectively.

Tung et al. (2012) studied styrene–butadiene–styrene block copolymers for use as oxygen scavenging polymers in barrier applications. They found that the oxygen uptake was kinetically limited for thin films but diffusion controlled for thick films.

Retort shock

Ethyl vinyl alcohol (EVOH) is the most common oxygen barrier material used in the production of plastic containers. Unfortunately, the oxygen barrier properties of EVOH decrease as the barrier layer absorbs water, which occurs during the hot retort processing (Müller 2013). Oxygen from the surrounding air can pass through the barrier layer during the drying stage, a phenomenon called retort shock (Dey 2012). The result is a significant quality loss during storage. A strategy to overcome the susceptibility of plastic packaging material to retort shock is to incorporate an oxygen scavenger layer into the packaging material structure (Gibis and Rieblinger 2011; Shah et al. 2015; Singh et al. 2011). In such cases, it is preferable to use oxygen scavengers activated by the autoclaving process. Any oxygen that penetrates during the cooling phase is, thus, immediately scavenged, considerably improving the quality of the packaged food (Mokwena and Tang 2012). The use of oxygen scavenging package for the pasteurization and sterilization of resistant plastic laminates is novel and innovative. It not only protects the product but also creates opportunities for designing novel packaging systems with fewer materials, possibly eliminating the need for additional aluminum layers.

Fischer et al. (2015) studied a PA/EVOH/PA structure that had previously been considered unsuitable for sterilization applications because of its large retort shock. They found that it could be used when the gas barrier layer was monoaxially stretched. Ideally, the gas barrier layer forms on the outside of the packaging film (facing away from the product) or is covered only by layers that have significant water vapor permeability, preferably at least as good as that of the PA sublayer. Their experiments showed that the retort shock could be restricted to a duration of 4 h in this way. In other words, after 4 h, the original gas barrier was (almost) completely reestablished. Lehner et al. (2015) extruded a multilayer film with pure PP and 20 wt% of an iron-based oxygen scavenger up to ten times at two temperature profiles. They found that the repeated extrusions reduced the oxygen absorption capacity at 23 °C by one-third, from 39 to 48 mg per gram of scavenger additive after one extrusion to 26 and 35 mg per gram of scavenger additive after nine and ten extrusion cycles, respectively.

Recent developments in oxygen scavenging films

Nanoactive oxygen-absorbing film

Because of their suitability and active functions, nanomaterials are already being implemented in the food packaging industry. Currently, the food processing industry is concentrating on creating new nanomaterials to enhance the mechanical and barrier properties of packaging (Peter et al. 2012). Busolo and Lagaron (2012) studied nanoiron-containing kaolinite incorporated into HDPE films as an active oxygen scavenging film, along with polyolefin nanocomposites. The active kaolinite clay has a high oxygen scavenging performance, as shown in Fig. 5. Nanoparticles of metallic iron with an average particle diameter of about 115 nm show high oxygen uptake kinetics at 100% relative humidity (RH).

Source: Adapted and modified from Busolo and Lagaron (2012)

Oxygen scavenging capacity of polyolefin/10% iron kaolinite at 100%RH.

Akkapeddi and Lynch (2014) used dispersed nanoparticles of a polymerizing monomer in the presence of a platinum group metal catalyst to obtain a polymer oxygen scavenging system. Containers made with this oxygen scavenging system could be used for food and beverage packaging because this scavenger exhibits high clarity and high oxygen scavenging properties. Llorens et al. (2012) investigated the incorporation of metal-based micro- and nanostructured materials, including Fe, into food-contact polymers to enhance the mechanical and barrier properties and prevent the photodegradation of the plastics. Additionally, heavy metals are effective compounds for preparation as elemental nanoparticles. They can be incorporated for food preservation purposes but can also scavenge oxygen and extend food shelf life.

The use of bio-based agents in nanoapplications has also been investigated. Byun et al. (2012) developed a warm-water fish gelatin film containing oxygen scavenging nanoparticles and iron (II) chloride. They compared their films with an unmodified fish gelatin film and found that their oxygen scavenging film had a rough surface, increased water vapor and oxygen permeabilities, and decreased tensile strength because of the agglomeration of the oxygen scavenging system. In their oxygen scavenging measurement tests, the initial oxygen content (%) in the cup headspace, 20.90%, decreased to 4.56% after 50 days of storage. The unmodified fish gelatin film also had a good oxygen scavenging capacity of 1969.08 mL/g. They used moisture to trigger the oxygen scavenging reaction.

Biodegradable oxygen-absorbing film

The increasing manufacture and use of synthetic plastic materials have been major concerns for many years because such plastics are difficult to degrade, creating waste disposal problems (Akkapeddi and Lynch 2014). In recent years, many efforts have been made to develop environmentally friendly products by incorporating bio-composite materials as an alternative to petroleum-based synthetic polymers (2016). Currently, the biodegradable polymer concept is emerging. Biodegradable polymeric materials are based on polysaccharides extracted from agricultural, marine, animal, or microbial sources, and they use renewable raw materials such as proteins. These materials are susceptible to degradation by environmental factors such as soil moisture, microorganisms, and oxygen (González and Alvarez Igarzabal 2013). Biodegradable polymers made from such renewable and natural polymers have received considerable interest in the food packaging industry. Scarfato et al. (2015) used biodegradable PLA and cast extrusion to develop an oxygen scavenging film for food packaging by incorporating microparticles of α-tocopherol as a natural antioxidant agent. Compared with a virgin PLA film, the developed aPLA film had acceptable mechanical, thermal, barrier, and optical properties and showed oxygen scavenging activity and prolonged exhaustion lag time. Mahieu et al. (2015) developed an extruded thermoplastic starch oxygen scavenging film with ascorbic acid and iron powder and studied its water sorption capacity, oxygen scavenging capabilities, and mechanical properties at different relative humidities. The film had excellent oxygen scavenging function that could be activated by increasing the relative humidity. When they blended the thermoplastic starch oxygen scavenging film with polycaprolactone (PCL), they found that the addition of 20% PCL slightly improved the mechanical properties at relative humidities (RH) lower than 72%. Recently, organosolv lignin and lignosulfonates have been used to prepare oxygen scavenging film materials in the form of coatings. The prepared active films were characterized using gel permeation chromatography, dynamic mechanical analysis, and wet stability, and those tests showed that using organosolv lignin and lignosulfonates improved the oxygen scavenging capability (Johanson et al. 2013). The use of biodegradable plastics is a new concept; hence, limited research has been done in this area.

Future trends

A bright future is anticipated for oxygen scavenging films in food packaging because they fit the food safety strategy, which involves an improved level of food safety and transparency to consumers. The use of oxygen scavengers in the form of sachets, films, and closures is well established in the commercial market, but the use of oxygen scavengers in plastics continues to attract researchers. New research depends on the focus of the food and packaging industries. A major motivator should be the curiosity of food scientists to seek ever better results when they introduce new products to the market. Another important motivator is the need to maintain current quality levels as newer packaging materials become available. This is already visible with the introduction of rigid jars, bottles, and glass. The potential effect on canned food has not yet been determined but is expected to be large.

The use of organic-based oxygen scavenging agents in film form has increased in the past few years because of their advantages over metallic-based scavengers. Several new oxygen scavenging agents have been studied in the past few years. The use of natural and biological oxygen scavengers entrapped in a polymer matrix will be the focus of future work. Possible scavengers include food-grade antioxidants such as vitamin E (α-tocopherol) and vitamin C. The use of immobilized aerobic microorganisms for oxygen scavenging has also been suggested. The development of more scavengers triggered by activation will prevent the premature loss of scavenging capacity. An oxygen scavenger that indicates the level of oxygen present could act as both an active and intelligent package component. The acceptance of new oxygen scavengers will depend on their safety for direct food contact and their inability to leach harmful substances into the food or beverage. The use of biopolymers as scavenging agents is another area of research. Some researchers have used PVA in their research, but its development is still in the early stages. The optimization of oxygen scavenging parameters is necessary to extend the shelf life of many food products. There is a need for research into the combination of oxygen scavenging packaging with other technologies. To protect the environment and minimize the pollution caused by packaging materials, the development of biodegradable and nanoactive films for packaging is increasingly being emphasized. The use of multilayer oxygen scavenging films will continue to be of interest because of the demanding legal requirements for food packaging. This will serve to drive not only packaging innovation, but also future research into scavenging agents and adhesives and the development of new tools for exposure estimation and compliance. Given the increasing interest in sustainable packaging, the effect of material recyclability should also be considered. The benefits of shelf life extension versus cost will drive future research and the widespread use of this technology. Nanotechnology is expected to play a major role in oxygen scavenging films, taking into account all additional safety considerations and filling the presently existing gaps in knowledge.

Challenges

Film processing

Difficulties in the processing of oxygen scavenging films present another challenge. The trend of using organic-based agents has increased in the past few years. However, organic agents are unstable at the high processing temperatures commonly used in extrusion; thus, it is challenging for researchers to incorporate such materials into polymer matrices.

Retained oxygen scavenging activity and stability

In the past 10 years, oxygen scavenging packaging has become the most commercially important category of antioxidant packaging materials (Dey 2012). The commercial application of an oxygen scavenging packaging material requires a rigorous evaluation of its functionality and stability; however, the oxygen scavenging efficiency of functional agents can be affected by their addition to a packaging material. One important technical hurdle to developing active packaging materials is finding a way to retain sufficient capacity of the active components after they have been applied to the packaging systems (De Jong et al. 2005). The efficiency of an oxygen scavenging material is likely to deteriorate during the film manufacturing process, which involves high temperatures, shearing force, and high pressure (Suppakul et al. 2003). The stability of oxygen scavenging packaging must also be evaluated in a variety of storage conditions to understand its performance profile better and to identify the optimal storage conditions for maximum activity retention (Gaikwad and Lee 2016). Among the oxygen scavenging substances, metallic and inorganic materials are relatively stable and are unaffected by the external environment. Therefore, to date, Fe-based materials have had the highest demand.

Film properties

The incorporation of oxygen scavenging systems and materials in a polymer matrix can influence the physical properties of the plastic, including the tensile strength, elongation, gas barrier, thermal properties, and optical properties. Damaj et al. (2015) reported that a PVA film containing a cobalt (II) complex with the ligand l-threonine as an oxygen scavenger had reduced transparency compared with pure PVA films. The tensile and break strength and thermal properties of LLDPE film declined with the addition of an iron-based scavenger (Shin et al. 2011). Therefore, careful evaluation of the physical properties must be performed to ensure that oxygen scavenging films maintain the desired properties, as well as to better understand the feasibility of commercialization on an industrial scale.

Optically transparent polymer films have been widely used in food packaging applications. Recently, the use of oxygen scavenging systems in the form of nanomaterials has received attention because of their high reactivities and surface areas. However, the dispersion of nanoparticles plays a crucial role in the transparency of the resulting polymer film. The active agents in the polymer film should be highly dispersed, and an improper dispersion in the polymer matrix can be caused by insufficient shear during processing or a high affinity with the polymer matrix.

Effects of different food processing methods on film

The food industry uses various techniques to prolong the shelf life of food, both thermal and nonthermal, such as retort and aseptic processing, microwave-assisted thermal sterilization, high- and ultra-high-pressure processing, and high-intensity light pulses. These methods can affect the physical properties of the oxygen scavenging film. In thermal processing, the used oxygen scavenging packaging films must resist high temperatures and mild pressures. Furthermore, the barrier properties should remain unaffected and not interact with the food product. In general, most oxygen scavengers, including iron-based scavengers, scavenge more oxygen at high temperatures, so it is critical to choose an appropriate oxygen scavenging system for the packaging material to avoid the absorption of oxygen during the processing stage. If this happens, the saturation of oxygen scavenging films will be very fast. Films containing iron-based oxygen scavengers can face problems during microwave-assisted thermal sterilization because of the iron in the packaging material. Therefore, the use of microwaves in processing is restricted. High-pressure processing is a promising new method for the treatment of foods with minimum quality loss. Here, foods are packaged and then placed in a pressure chamber (up to 400 MPa) for 5–20 min. Because of the high pressure, the physical properties of the oxygen scavenging process can change. Caner et al. reported that there is a significant increase in the oxygen, carbon dioxide, and water vapor permeabilities of metallized PET films when treated at 500 MPa for 30 min.

Migration of active compounds

Given the deliberate interaction between food and the package, a stringent examination of the safety of active packaging is both necessary and more challenging than with traditional packaging. New dedicated migration tests and mass transfer modeling tools must be developed because the existing methods for traditional packaging might not be properly adapted to active systems. Potentially toxic migrants are a technical challenge because the active component must be compatible with the packaging material. The acceptable level of migration is set by regulating agencies, such as the US Food and Drug Administration (FDA) and the European Union (EU). The migration of oxygen scavenging chemicals is a challenge for researchers because they must consider all breakdown products and their toxicity. The compliance of active packaging with food legislation will be closely related to the migration of the film components. Assessing migration implies the development of dedicated migration tests and mass transfer modeling tools.

Control of by-products

The control of by-products from organic-based scavenging agents is the biggest challenge in food packaging. By-products include gases that can generate an off-flavor and change the appearance of food products. Such gases can also be harmful to humans.

Saturation level

Mostly, oxygen scavenger films reach their saturation point rapidly. If the oxygen scavenging film rapidly reaches oxygen saturation, via permeation through the package wall, the oxygen which permeates through the package wall can saturate in the headspace of package. This oxygen is responsible for microbial growth (in high water activity foods), as well as the generation of off-flavors, changes in color and taste, and ultimately a reduction in product quality and shelf life. To overcome such issues, first, the oxygen scavenging film should scavenge oxygen slowly and over an extended period; otherwise, the scavenging film will rapidly reach saturation and lose its capacity to trap more oxygen from the headspace of the package, as well oxygen permeating from the outside environment. Secondly, the packaging agents should be a strong barrier to oxygen, i.e., a value not greater than 20 mL/m2 day atm for packages in which an oxygen scavenger is used so that oxygen from the outside environment will not permeate into package and the scavenger present in the package will scavenge only the oxygen present in package/headspace. Third, for flexible packaging, heat sealing must be complete so that no air enters the package via the sealed portion. Lastly, the quantity of the oxygen scavenger must be commensurate with the size of the package.

Health concern

Oxygen scavengers such as iron oxides are harmful to human health. Such as, exposure to iron oxide can cause fever, body aches, chest tightness, cough, and pneumoconiosis. These health hazards related to oxygen scavengers have led to the implementation of various regulations pertaining to the handling of harmful chemicals. This is one of the major challenges for the growth of the oxygen scavengers market in the coming years.

Regulation of active packaging

The increasing development of active packaging technologies challenges the current regulatory framework, which must now address new technical considerations to ensure the safety, quality, and stability of food products that use such packaging. Although the legislation applied to traditional packaging can be adapted to active packaging, specific laws and guidelines should be introduced to clarify the legal uses of novel technologies in food packaging. In the USA, current FDA regulatory programs include the food additive petition (FAP) program, generally recognized as safe (GRAS) notification program, and food contact substance (FCS) notification program, which provide an authorization process for direct food additives, GRAS substances, and indirect additives, respectively (Koontz 2012). Migratory active packaging should follow the FAP program or GRAS notification because this technology releases antioxidants into food as an intended technical effect. Nonmigratory antioxidant packaging needs to follow the FCS notification program because the active agent is unlikely to migrate to the food (Koontz 2012). Japan is also leading the development and use of active packaging for food, and active packaging concepts have penetrated markets in Australia. The development of active packaging in the EU market is limited, and most of the products already on the market in the USA, Japan, and Australia cannot yet be introduced in Europe because of the inadequate and stringent EU legislation. The regulation of active packaging in the EU is still evolving, and certain inherent constraints in the law (such as the overall migration limit) result in a set of hurdles, preventing regulation from keeping up with rapidly developing technological innovations. The new active and intelligent packaging directive introduced in 2009 across Europe (EC Regulation 450/2009) is expected to bring much-needed clarity to this sector and pave the way for the launch of new products in the European market.

Consumer acceptance

Food producer, consumer, and retail acceptance are required to enable the introduction of active packaging on a large scale. A survey of European countries investigated consumer attitudes and found that most consumers were open to innovations in this area, provided the agents are safe and the information concerning these products is unambiguous.

Conclusions

Oxygen scavenging active films have great potential to become appropriate packaging material for oxygen-sensitive foods. Research in this field has increased in the past few years, but some problems remain to be solved before such films can be applied to the mass packaging of consumer goods, particularly difficulties in processing and scavenging efficiency. Nevertheless, some oxygen scavenging films have been commercialized and are already available. These films are based on iron, but future trends will favor organic-based oxygen scavenging systems because of the limitations of metal-based scavengers.

References

Ahn BJ, Gaikwad KK, Lee YS (2016) Characterization and properties of LDPE film with gallic-acid-based oxygen scavenging system useful as a functional packaging material. J Appl Polym Sci 133:1–8. https://doi.org/10.1002/app.44138

Akkapeddi MK, Lynch BA (2014) Oxygen scavenging compositions requiring no induction period. U.S. Patent Application 14/861,481

Anonymous (2017a) Oxygen scavengers market by type (metallic, and non-metallic), end-use industry (food & beverage, pharmaceutical, power, oil & gas, chemical, pulp & paper), and region—global forecast to 2022. July 2017. www.marketsandmarkets.com

Anonymous (2017b) Oxygen scavenger market: global industry analysis and opportunity assessment 2017–2027. Market research report. REP-GB-3150 October 2017. http://www.futuremarketinsights.com/reports/oxygen-scavenger-market

Anthierens T, Ragaert P, Verbrugghe S, Ouchchen A, De Geest BG, Noseda B, Mertens J, Beladjal L, De Cuyper D, Dierickx W, Du Prez F (2011) Use of endospore-forming bacteria as an active oxygen scavenger in plastic packaging materials. Innov Food Sci Emerg Technol 12:594–599. https://doi.org/10.1016/j.ifset.2011.06.008

Barish JA, Goddard JM (2011) Topographical and chemical characterization of polymer surfaces modified by physical and chemical processes. J Appl Polym Sci 120:2863–2871. https://doi.org/10.1002/app.33310

Beckwith S, Edwards FB, Rivett J, Ebner CL, Kennedy T, McDowell R, Speer DV (2014) multilayer film having passive and active oxygen barrier layers. U.S. Patent No. 8,815,360

Brody AL, Strupinsky ER, Kline LR (2001) Active packaging for food applications. CRC Press, Boca Raton

Busolo MA, Lagaron JM (2012) Oxygen scavenging polyolefin nanocomposite films containing an iron modified kaolinite of interest in active food packaging applications. Innov Food Sci Emerg Technol 16:211–217. https://doi.org/10.1016/j.ifset.2012.06.008

Byun Y, Whiteside S (2012) Ascorbyl palmitate-β-cyclodextrin inclusion complex as an oxygen scavenging microparticle. Carbohyd Polym 87:2114–2119. https://doi.org/10.1016/j.carbpol.2011.10.037

Byun Y, Bae HJ, Whiteside S (2012) Active warm-water fish gelatin film containing oxygen scavenging system. Food Hydrocoll 27:250–255. https://doi.org/10.1016/j.foodhyd.2011.06.010

Cardona ED, Noriega MP, Sierra JD (2011) Oxygen scavengers impregnated in porous activated carbon matrix for food and beverage packaging applications. J Plast Film Sheet 28:63–78. https://doi.org/10.1177/8756087911427730

Castro López M, López de Dicastillo C, López Vilariño JM, González Rodríguez MV (2013) Improving the capacity of polypropylene to be used in antioxidant active films: incorporation of plasticizer and natural antioxidants. J Agric Food Chem 61:8462–8470. https://doi.org/10.1021/jf402670a

Ching TY, Goodrich JL, Katsumoto K (2000) U.S. Patent No. 6,057,013. Washington, DC: U.S. Patent and Trademark Office

Choi WS, Singh S, Lee YS (2016) Characterization of edible film containing essential oils in hydroxypropyl methylcellulose and its effect on quality attributes of ‘Formosa’plum (Prunus salicina L.). LWT Food Sci Technol 70:213–222. https://doi.org/10.1016/j.lwt.2016.02.036

Cichello SA (2015) Oxygen absorbers in food preservation: a review. J Food Sci Technol 52:1889–1895. https://doi.org/10.1007/s13197-014-1265-2

Cruz RS, Camilloto GP, Pires AC (2012) Oxygen scavengers: an approach on food preservation. In: Eissa AA (ed) Structure and function of food engineering. InTech, Rijeka, Croatia, pp 21–42. https://doi.org/10.5772/48453

Damaj Z, Joly C, Guillon E (2015) Toward new polymeric oxygen scavenging systems: formation of poly (vinyl alcohol) oxygen scavenger film. Packag Technol Sci 28:293–302. https://doi.org/10.1002/pts.2112

De Azeredo HM (2009) Nanocomposites for food packaging applications. Food Res Int 42:1240–1253. https://doi.org/10.1016/j.foodres.2009.03.019

De Jong AR, Boumans H, Slaghek T, Van Veen J, Rijk R, Van Zandvoort M (2005) Active and intelligent packaging for food: is it the future? Food Addit Contam 22:975–979. https://doi.org/10.1080/02652030500336254

Demicheva M (2015) Novel oxygen scavenger systems for functional coatings. http://urn.fi/URN:NBN:fi:amk-201502122166

Dey SK (2012) Metal closure having an oxygen scavenging interior surface. U.S. Patent No. 9,617,049

Di Maio L, Scarfato P, Avallone E, Galdi MR, Incarnato L (2014) Preparation and characterization of biodegradable active PLA film for food packaging. In: AIP conference proceedings, AIP, pp 338–341

Di Maio L, Scarfato P, Galdi MR, Incarnato L (2015) Development and oxygen scavenging performance of three-layer active PET films for food packaging. J Appl Polym Sci 132(7). https://doi.org/10.1002/app.41465

Fava F, Marson A, Steffanut P, Johann L (2013) Oxygen scavenging plastic material. U.S. Patent Application 14/429,289

Ferrari MC, Carranza S, Bonnecaze RT, Tung KK, Freeman BD, Paul DR (2009) Modeling of oxygen scavenging for improved barrier behavior: blend films. J Membr Sci 329:183–192. https://doi.org/10.1016/j.memsci.2008.12.030

Fischer L, Sperlich B, Nelke-Bruhn D, Kaeding-Koppers A (2015) Packaging film and packaging process. U.S. Patent Application No. 14/847,568

Gaikwad KK, Lee YS (2016) Novel natural phenolic compound-based oxygen scavenging system for active packaging applications. J Food Meas Charact 10:533–538. https://doi.org/10.1007/s11694-016-9332-1

Gaikwad KK, Lee YS (2017) Effect of storage conditions on the absorption kinetics of non-metallic oxygen scavenger suitable for moist food packaging. J Food Meas Charact 11(3):965–971. https://doi.org/10.1007/s11694-017-9470-0

Gaikwad KK, Singh S, Shakya BR (2013) Studies on the development and shelf life of low calorie herbal aonla-ginger RTS beverage by using artificial sweeteners. J Food Process Technol 4(200):2. https://doi.org/10.4172/2157-7110.1000200

Gaikwad KK, Lee JY, Lee YS (2016) Development of polyvinyl alcohol and apple pomace bio-composite film with antioxidant properties for active food packaging application. J Food Sci Technol 53:1608–1619. https://doi.org/10.1007/s13197-015-2104-9

Gaikwad KK, Lee SM, Lee JS, Lee YS (2017a) Development of antimicrobial polyolefin films containing lauroyl arginate and their use in the packaging of strawberries. J Food Meas Charact. https://doi.org/10.1007/s11694-017-9551-0

Gaikwad KK, Singh S, Lee YS (2017b) A pyrogallol-coated modified LDPE film as an oxygen scavenging film for active packaging materials. Prog Org Coat 111:186–195. https://doi.org/10.1016/j.porgcoat.2017.05.016

Galdi MR, Nicolais V, Maio LD, Incarnato L (2008) Production of active pet film: evaluation of scavenging activity. Packag Technol Sci 21:257–268. https://doi.org/10.1002/pts.794

Gauthier W (2015) Apparatus and method for extending polyolefin containing photovoltaic panel life span. U.S. Patent No. 8,941,006

Gibis D, Rieblinger K (2011) Oxygen scavenging films for food application. Procedia Food Sci 1:229–234. https://doi.org/10.1016/j.profoo.2011.09.036

Goddard JM, Hotchkiss JH (2007) Polymer surface modification for the attachment of bioactive compounds. Prog Polym Sci 32:698–725. https://doi.org/10.1016/j.progpolymsci.2007.04.002

González A, Alvarez Igarzabal CI (2013) Soy protein—poly (lactic acid) bilayer films as biodegradable material for active food packaging. Food Hydrocoll 33:289–296. https://doi.org/10.1016/j.foodhyd.2013.03.010

Graf E (1994) U.S. Patent No. 5,284,871. U.S. Patent and Trademark Office, Washington

Herbert MM, Schiraldi DA (2014) Abstr Pap Am Chem Soc 248:1155

Irkin R, Esmer OK (2015) Novel food packaging systems with natural antimicrobial agents. J Food Sci Technol 52:6095–6111. https://doi.org/10.1007/s13197-015-1780-9

Jamshidian M, Tehrany EA, Cleymand F, Leconte S, Falher T, Desobry S (2012) Effects of synthetic phenolic antioxidants on physical, structural, mechanical and barrier properties of poly lactic acid film. Carbohydr Polym 87:1763–1773. https://doi.org/10.1016/j.carbpol.2011.09.089

Janjarasskul T, Suppakul P (2016) Active and intelligent packaging: the indication of quality and safety. Crit Rev Food Sci. https://doi.org/10.1080/10408398.2016.1225278

Janjarasskul T, Tananuwong K, Krochta JM (2011) Whey protein film with oxygen scavenging function by incorporation of ascorbic acid. J Food Sci 76(9):561–568. https://doi.org/10.1111/j.1750-3841.2011.02409.x

Järnström L, Johansson K, Jönsson LJ, Winestrand S, Chatterjee R, Nielsen T, Kotkamo S (2013) Enzymes embedded in barrier coatings for active packaging. Nordic Innov Publ 203:1–96

Jo C, Ahn DU, Byun MW (2002) Irradiation-induced oxidative changes and production of volatile compounds in sausages prepared with vitamin E-enriched commercial soybean oil. Food Chem 76:299–305. https://doi.org/10.1016/S0308-8146(01)00276-X

Johansson K, Christophliemk H, Johansson C, Jönsson LJ, Järnström L (2013) The effects of coating structure and water-holding capacity on the oxygen-scavenging ability of enzymes embedded in the coating layer. TAPPI J 12(6):43–52.

Johansson K, Gillgren T, Winestrand S, Järnström L, Jönsson LJ (2014) Comparison of lignin derivatives as substrates for laccase-catalyzed scavenging of oxygen in coatings and films. J Biol Eng 8:1. https://doi.org/10.1186/1754-1611-8-1

Johnson DR, Decker EA (2015) The role of oxygen in lipid oxidation reactions: a review. Annu Rev Food Sci Technol 6:171–190. https://doi.org/10.1146/annurev-food-022814-015532

Joven R, Garcia A, Arias A, Medina J (2015) Development of an active thermoplastic film with oxygen scavengers made of activated carbon and sodium erythorbate. Packag Technol Sci 28:113–121. https://doi.org/10.1002/pts.2093

Koontz J (2012) Active packaging materials to inhibit lipid oxidation: US regulatory framework. Inform 23:598–600

Labuza TP, Breene WM (1989) Applications of “active packaging” for improvement of shelf-life and nutritional quality of fresh and extended shelf-life foods. J Food Process Preserv 13:1–69. https://doi.org/10.1111/j.1745-4549.1989.tb00090.x

Lehner M, Schlemmer D, Sängerlaub S (2015) Recycling of blends made of polypropylene and an iron-based oxygen scavenger—influence of multiple extrusions on the polymer stability and the oxygen absorption capacity. Polym Degrad Stab 122:122–132. https://doi.org/10.1016/j.polymdegradstab.2015.10.020

Li H, Tung KK, Paul DR, Freeman BD, Stewart ME, Jenkins JC (2012) Characterization of oxygen scavenging films based on 1, 4-polybutadiene. Ind Eng Chem Res 51:7138–7145. https://doi.org/10.1021/ie201905j

Llorens A, Lloret E, Picouet PA, Trbojevich R, Fernandez A (2012) Metallic-based micro and nanocomposites in food contact materials and active food packaging. Trends Food Sci Technol 24:19–29. https://doi.org/10.1016/j.tifs.2011.10.001

Mabeck JT, Malliaras GG (2006) Chemical and biological sensors based on organic thin-film transistors. Anal Bioanal Chem 384:343–353. https://doi.org/10.1007/s00216-005-3390-2

Mahieu A, Terrié C, Youssef B (2015) Thermoplastic starch films and thermoplastic starch/polycaprolactone blends with oxygen-scavenging properties: influence of water content. Ind Crops Prod 72:192–199. https://doi.org/10.1016/j.indcrop.2014.11.037

Marsh K, Bugusu B (2007) Food packaging-roles, materials, and environmental issues. J Food Sci 72(3):39–55. https://doi.org/10.1111/j.1750-3841.2007.00301.x

Matche RS, Sreekumar RK, Raj B (2011) Modification of linear low-density polyethylene film using oxygen scavengers for its application in storage of bun and bread. J Appl Polym Sci 122:55–63. https://doi.org/10.1002/app.33718

Mills A, Doyle G, Peiro AM, Durrant J (2006) Demonstration of a novel, flexible, photocatalytic oxygen-scavenging polymer film. J Photochem Photobiol A 177:328–331. https://doi.org/10.1016/j.jphotochem.2005.06.001

Mokwena KK, Tang J (2012) Ethylene vinyl alcohol: a review of barrier properties for packaging shelf stable foods. Crit Rev Food Sci Nutr 52:640–650. https://doi.org/10.1080/10408398.2010.504903

Mølgaard SL, Henriksson M, Cárdenas M, Svagan AJ (2014) Cellulose-nanofiber/polygalacturonic acid coatings with high oxygen barrier and targeted release properties. Carbohydr Polym 114:179–182. https://doi.org/10.1016/j.carbpol.2014.08.011

Mu H, Gao H, Chen H, Tao F, Fang X, Ge L (2013) A nanosised oxygen scavenger: preparation and antioxidant application to roasted sunflower seeds and walnuts. Food Chem 136:245–250. https://doi.org/10.1016/j.foodchem.2012.07.121

Müller K (2013) Multilayer films for bag-in-container systems used in disposable kegs: basic principles of possible barrier concepts. Brew Sci 66:31–36

Nayik GA, Muzaffar K (2014) Developments in packaging of fresh fruits-shelf life perspective: a review. Am J Food Sci Nutr Res 1:34–39

Odian GG (1991) Principles of polymerization, 3rd edn. Wiley-Interscience publication, New York

Pant AF, Sängerlaub S, Müller K (2017) Gallic acid as an oxygen scavenger in bio-based multilayer packaging films. Materials 10:489. https://doi.org/10.3390/ma10050489

Peter A, Nicula C, Mihaly-Cozmuta A, Mihaly-Cozmuta L, Indrea E (2012) Chemical and sensory changes of different dairy products during storage in packages containing nanocrystallised TiO2. Int J Food Sci Technol 47:1448–1456. https://doi.org/10.1111/j.1365-2621.2012.02992.x

Sakanaka S, Tachibana Y (2006) Active oxygen scavenging activity of egg-yolk protein hydrolysates and their effects on lipid oxidation in beef and tuna homogenates. Food Chem 95:243–249. https://doi.org/10.1016/j.foodchem.2004.11.056

Sängerlaub S, Gibis D, Kirchhoff E, Tittjung M, Schmid M, Müller K (2013) Compensation of pinhole defects in food packages by application of iron-based oxygen scavenging multilayer films. Packag Technol Sci 26:17–30. https://doi.org/10.1002/pts.1962

Scarfato P, Di Maio L, Incarnato L (2015) Recent advances and migration issues in biodegradable polymers from renewable sources for food packaging. J Appl Polym Sci 132:48. https://doi.org/10.1002/app.42597

Shah BA, Vanderwende GL, Khasat NP, Restaino MC (2015) Polymer sheet with improved barrier properties. U.S. Patent Application No. 14/611,249

Shin Y, Shin J, Lee YS (2011) Preparation and characterization of multilayer film incorporating oxygen scavenger. Macromol Res 19:869–875. https://doi.org/10.1007/s13233-011-0912-y

Singh P, Abas Wani A, Saengerlaub S (2011) Active packaging of food products: recent trends. Nutr Food Sci 41:249–260. https://doi.org/10.1108/00346651111151384

Singh S, ho Lee M, Shin Y, Lee YS (2016a) Antimicrobial seafood packaging: a review. J Food Sci Technol Mysore 53:2505–2518. https://doi.org/10.1007/s13197-016-2216-x

Singh S, Gaikwad KK, Omre PK, Lee YS (2016b) Process development for stabilization of sugarcane juice using response surface methodology. J Food Meas Charact 10:727–737. https://doi.org/10.1007/s11694-016-9357-5

Singh S, ho Lee M, Park I, Shin YJ, Lee YS (2016c) Antimicrobial properties of polypropylene films containing AgSiO2, AgZn and AgZ for returnable packaging in seafood distribution. J Food Meas Charact 10:781–793. https://doi.org/10.1007/s11694-016-9363-7

Singh S, Gaikwad KK, Lee M, Lee YS (2017a) Thermally buffered corrugated packaging for preserving the postharvest freshness of mushrooms (Agaricus bispours). J Food Eng. https://doi.org/10.1016/j.jfoodeng.2017.07.013

Singh S, Gaikwad KK, Park SI, Lee YS (2017b) Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. Int J Biol Macromol 99:506–510. https://doi.org/10.1016/j.ijbiomac.2017.03.004

Sirviö JA, Kolehmainen A, Visanko M, Liimatainen H, Niinimäki J, Hormi OE (2014) Strong, self-standing oxygen barrier films from nanocelluloses modified with regioselective oxidative treatments. ACS Appl Mater Interfaces 6:14384–14390. https://doi.org/10.1021/am503659j

Sun DW (2016) Computer vision technology for food quality evaluation. Academic Press, London

Suppakul P, Miltz J, Sonneveld K, Bigger SW (2003) Active packaging technologies with an emphasis on antimicrobial concise reviews in food science. J Food Sci 68:408–420. https://doi.org/10.1111/j.1365-2621.2003.tb05687.x

Tung KK, Bonnecaze RT, Freeman BD, Paul DR (2012) Characterization of the oxygen scavenging capacity and kinetics of SBS films. Polymer 53:4211–4221. https://doi.org/10.1016/j.polymer.2012.07.028

Vermeiren L, Devlieghere F, Van Beest M, De Kruijf N, Debevere J (1999) Developments in the active packaging of foods. Trends Food Sci Technol 10:77–86. https://doi.org/10.1016/S0924-2244(99)00032-1

Winestrand S, Johansson K, Järnström L, Jönsson LJ (2013) Co-immobilization of oxalate oxidase and catalase in films for scavenging of oxygen or oxalic acid. Biochem Eng J 72:96–101. https://doi.org/10.1016/j.bej.2013.01.006

Wong DE, Andler SM, Lincoln C, Goddard JM, Talbert JN (2017) Oxygen scavenging polymer coating prepared by hydrophobic modification of glucose oxidase. J Coat Technol Res 14:489–495. https://doi.org/10.1007/s11998-016-9865-6

Xiao-e L, Green AN, Haque SA, Mills A, Durrant JR (2004) Light-driven oxygen scavenging by titania/polymer nanocomposite films. J Photochem Photobiol A 162(2):253–259. https://doi.org/10.1016/j.nainr.2003.08.010

Yildirim S, Röcker B, Rüegg N, Lohwasser W (2015) Development of palladium-based oxygen scavenger: optimization of substrate and palladium layer thickness. Packag Technol Sci 28:710–718. https://doi.org/10.1002/pts.2134

Acknowledgements

The authors would like to thank the Ministry of Trade, Industry and Energy (MOTIE, Korea) under industry technology innovation program for financial support. This research study is part of a project titled “Development of multi-functional porous ceramic convergence materials for high-quality keeping freshness packaging” (No. 10063291).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaikwad, K.K., Singh, S. & Lee, Y.S. Oxygen scavenging films in food packaging. Environ Chem Lett 16, 523–538 (2018). https://doi.org/10.1007/s10311-018-0705-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-018-0705-z