Abstract

In the past, researchers have attempted to model trabecular bone using computational techniques. However, only a few of these models are visually similar, but not representative of the microstructural characteristics of real trabecular bones. In this study, we hypothesized that probabilistic modeling approaches could be used to generate representative digital models that capture the microstructural features of real trabecular bones. To test this hypothesis, we proposed a novel mathematical framework to build the digital models and compared the digital models to real bone specimens. First, an initial three-dimensional cellular structure was generated using Voronoi tessellation, with the faces and edges of the Voronoi cells considered as a pool of potential trabecular plates and rods, respectively. Then, inverse Monte Carlo simulations were performed to select, delete, or reassign plates and rods until the underlying size, orientation, and spatial distributions of the plates and rods converged to the target distributions obtained from real trabecular bone microstructures. Next, digital graphics techniques were used to define the thickness of trabecular plates and the diameter of trabecular rods, followed by writing the model into a Standard Tessellation Language file and then smoothing the model surfaces for a more natural appearance. To verify the efficacy of the digital model in capturing the microstructural features of real trabecular bones, forty-six digital models with a large variation in microstructural features were generated based on the target distributions obtained from trabecular bone specimens of twelve human cadaveric femurs. Then, the histomorphological parameters of the digital models were compared with those of the real trabecular bone specimens. The results indicate that the digital models are capable of capturing major microstructural features of the trabecular bone samples, thus proving the hypothesis that the proposed probabilistic modeling approach could render real trabecular bone microstructures.

Similar content being viewed by others

References

Aurenhammer F (1991) Voronoi diagrams—a survey of a fundamental geometric data structure. ACM Comput Surv (CSUR) 23(3):345–405

Chang WC et al (1999) Uniaxial yield strains for bovine trabecular bone are isotropic and asymmetric. J Orthop Res 17(4):582–585

Chuang Y-W et al (2017) Multiple bony injuries on bone scan in a case of unsuspected child abuse. Case Rep Med 2017:3015941

Ditzler G, Polikar R (2011) Hellinger distance based drift detection for nonstationary environments. In: 2011 IEEE symposium on computational intelligence in dynamic and uncertain environments (CIDUE)

Dong XN, Shirvaikar M, Wang X (2013) Biomechanical properties and microarchitecture parameters of trabecular bone are correlated with stochastic measures of 2D projection images. Bone 56(2):327–336

Dong XN et al (2015) Stochastic predictors from the DXA scans of human lumbar vertebrae are correlated with the microarchitecture parameters of trabecular bone. J Biomech 48(12):2968–2975

Doube M et al (2010) BoneJ: Free and extensible bone image analysis in ImageJ. Bone 47(6):1076–1079

Fang Z et al (2018) The multi-axial failure response of porcine trabecular skull bone estimated using microstructural simulations. J Biomech Eng 140(10):101002

Fonseca H et al (2014) Bone quality: the determinants of bone strength and fragility. Sports Med 44(1):37–53

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties, 2nd edn. Cambridge University Press, Cambridge

Goldstein SA (1987) The mechanical properties of trabecular bone: dependence on anatomic location and function. J Biomech 20(11–12):1055–1061

Grecu D et al (2010) Numerical simulations of the 3D virtual model of the human hip joint, using finite element method. Rom J Morphol Embryol 51(1):151–155

Gross D, Li M (2002) Constructing microstructures of poly- and nanocrystalline materials for numerical modeling and simulation. Appl Phys Lett 80(5):746–748

Jensen KS, Mosekilde L, Mosekilde L (1990) A model of vertebral trabecular bone architecture and its mechanical properties. Bone 11(6):417–423

Kafka V, Jirova J (1983) A structural mathematical model for the viscoelastic anisotropic behaviour of trabecular bone. Biorheology 20(6):795–805

Keaveny TM, Hayes WC (1993) A 20-year perspective on the mechanical properties of trabecular bone. J Biomech Eng 115(4B):534–542

Keaveny TM et al (1994) Trabecular bone exhibits fully linear elastic behavior and yields at low strains. J Biomech 27(9):1127–1136

Keaveny TM et al (2001) Biomechanics of trabecular bone. Annu Rev Biomed Eng 3:307–333

Keen DA, Tucker MG, Dove MT (2005) Reverse Monte Carlo modelling of crystalline disorder. J Phys Condens Matter 17(5):S15–S22

Kopperdahl DL, Keaveny TM (1998) Yield strain behavior of trabecular bone. J Biomech 31(7):601–608

Kowalczyk P (2003) Elastic properties of cancellous bone derived from finite element models of parameterized microstructure cells. J Biomech 36(7):961–972

Lai YM et al (2005) Regional differences in trabecular BMD and micro-architecture of weight-bearing bone under habitual gait loading–a pQCT and microCT study in human cadavers. Bone 37(2):274–282

Liu XS et al (2006) Quantification of the roles of trabecular microarchitecture and trabecular type in determining the elastic modulus of human trabecular bone. J Bone Miner Res 21(10):1608–1617

Liu XS et al (2008) Complete volumetric decomposition of individual trabecular plates and rods and its morphological correlations with anisotropic elastic moduli in human trabecular bone. J Bone Miner Res 23(2):223–235

Lowitz T et al (2014) A digital model to simulate effects of bone architecture variations on texture at spatial resolutions of CT, HR-pQCT, and muCT scanners. J Med Eng 2014:946574

McFarland JM, Riha DS (2017) Probabilistic analysis using NESSUS (Numerical Evaluation of Stochastic Structures Under Stress). In: Ghanem R, Higdon D, Owhadi H (eds) Handbook of uncertainty quantification. Springer, Cham, pp 1733–1764

McGreevy RL (2001) Reverse monte carlo modelling. J Phys Condens Matter 13(46):R877

McGreevy R, Pusztai L (1988) Reverse Monte Carlo simulation: a new technique for the determination of disordered structures. Mol Simul 1(6):359–367

Mizrahi J et al (1993) Finite-element stress analysis of the normal and osteoporotic lumbar vertebral body. Spine 18(14):2088–2096

Mollon G, Zhao J (2012) Fourier–Voronoi-based generation of realistic samples for discrete modelling of granular materials. Granul Matter 14(5):621–638

Morgan EF, Keaveny TM (2001) Dependence of yield strain of human trabecular bone on anatomic site. J Biomech 34(5):569–577

Muller R (2005) Long-term prediction of three-dimensional bone architecture in simulations of pre-, peri- and post-menopausal microstructural bone remodeling. Osteoporos Int J 16(Suppl 2):S25–S35

Okabe A et al (2000a) Definitions and basic properties of voronoi diagrams, Spatial Tessellations: concepts and applications of Voronoi diagrams. Wiley, Hoboken, pp 43–112

Okabe A et al (2000b) Algorithms for computing Voronoi diagrams, spatial tessellations: concepts and applications of Voronoi diagrams. Wiley, Hoboken, pp 229–290

Okabe A et al (2000c) Generalizations of the Voronoi diagram, spatial tessellations: concepts and applications of Voronoi diagrams. Wiley, Hoboken, pp 113–228

Parkinson IH et al (2012) Vertebral body bone strength: the contribution of individual trabecular element morphology. Osteoporos Int J 23(7):1957–1965

Roberts AP, Garboczi EJ (2002) Computation of the linear elastic properties of random porous materials with a wide variety of microstructure. Proc R Soc Lond A 458:1033–1054

Shen R et al (2019) A novel phase field method for modeling the fracture of long bones. Int J Numer Methods Biomed Eng 35(8):e3211

Sieger D, Alliez P, Botsch M (2010) Optimizing voronoi diagrams for polygonal finite element computations. In: Proceedings of the 19th international meshing roundtable. Springer, New York, pp 335–350

Silva MJ, Gibson LJ (1997) Modeling the mechanical behavior of vertebral trabecular bone: effects of age-related changes in microstructure. Bone 21(2):191–199

Stauber M, Müller R (2006) Volumetric spatial decomposition of trabecular bone into rods and plates—a new method for local bone morphometry. Bone 38(4):475–484

Xu T, Li M (2009) Topological and statistical properties of a constrained Voronoi tessellation. Phil Mag 89(4):349–374

Yeh OC, Keaveny TM (1999) Biomechanical effects of intraspecimen variations in trabecular architecture: a three-dimensional finite element study. Bone 25(2):223–228

Yeni YN et al (2011) Variability of trabecular microstructure is age-, gender-, race- and anatomic site-dependent and affects stiffness and stress distribution properties of human vertebral cancellous bone. Bone 49(4):886–894

Zhao F et al (2018) Commonality in the microarchitecture of trabecular bone: a preliminary study. Bone 111:59–70

Acknowledgements

The authors are grateful to Dr. Yufei Huang for his constructive comments and discussion on probabilistic modeling and Mr. Peter Mancuso for his assistance in developing the code to render trabecular thickness (plate thickness and rod diameter) in the digital model. This work received computational support from UTSA’s HPC cluster SHAMU, operated by the Office of Information Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors state that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices

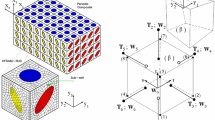

1.1 A: Reduction in the number of short Voronoi cell edges (rods)

One challenge with the random generation of seed points for Voronoi tessellation according to a binomial point process is the likelihood of creating a significant number of Voronoi cells with short edges (Sieger et al. 2010). This is because cell edges represent potential rods in the digital model and the Voronoi cell edge distribution is considerably right-skewed (positively skewed) compared to a real trabecular rod distribution, making it difficult to refine the rod length distribution in the digital model to be in agreement with the real bone rod length distribution (Appendix Fig. 9). Voronoi cell edges are defined during Delaunay triangulation as a line segment connecting the circumcenters of neighboring tetrahedrons, and thus, circumcenters that are in close proximity to one another form short Voronoi cell edges (Okabe et al. 2000). Tetrahedrons with circumcenters located near the incenter maximize the length of the Voronoi cell edges (Sieger et al. 2010). In addition to concerns about the rod length distribution in the digital model, previous research showed that it was difficult to refine the rod spatial arrangement distribution in the digital model to be in agreement with the real bone rod spatial arrangement distribution. Therefore, an inverse Monte Carlo process focused on rod length and rod spatial arrangement was employed to refine the placement of seed points within the volume domain prior to the selection of an optimum initial Voronoi cellular model.

In more detail, after the initial seed points were generated within the volume domain, Delaunay triangulation was performed, and based on the circumcenters of the tetrahedrons, Voronoi cell edge lengths and centroids (i.e., midpoints) of the edges were calculated. Note that Voronoi cell parameters were estimated from the Delaunay triangulation in order to keep computational costs low, as compared to generating a full Voronoi diagram for each iteration of the inverse Monte Carlo simulation. In general, plates are preferentially aligned vertically and rods are preferentially aligned horizontally, according to a previous study (Liu et al. 2008). Thus, horizontally oriented edges (Voronoi cell edges for which the colatitudinal angle was between 62.5° and 112.5°) were identified, and the focus of the inverse Monte Carlo process was on reducing the error in the length and spatial arrangement distributions of the horizontally oriented edges. The distribution of nearest neighbor distances between the centroids of the horizontally oriented cell edges was calculated to determine the spatial arrangement distribution. The inverse Monte Carlo process involved randomly selecting one of the existing seed points in the volume domain, temporarily deleting it, regenerating a random temporary seed point in its place, and recalculating the length and spatial arrangement distribution of the horizontally oriented cell edges. Then, the horizontal edge length and spatial arrangement distributions in the model were compared to the real trabecular bone rod length and rod spatial arrangement distributions and the error sum of squares (SSE) was computed. If both the length SSE and the spatial arrangement SSE were reduced and there was not a significant change in the number of non-horizontal cell edges, then the new seed point was accepted and the temporary deletion of the previous seed point was made permanent; otherwise, the new seed point was rejected and the previous seed point was restored. This procedure was performed for 15,000 inverse Monte Carlo simulation iterations or until the error was reduced to a value less than a specified threshold (in general < 0.001).

1.2 B: Inverse Monte Carlo simulations

We developed the algorithms for the inverse Monte Carlo procedures in MATLAB (Mathworks®) and performed the random sampling using the in-built randi function, which generated uniformly distributed pseudorandom integers. In more detail, all of the elements (e.g., plates and/or rods) involved in the inverse Monte Carlo simulations were stored in a single data array in MATLAB. Each element in the array was assigned a corresponding integer that denoted its position in the data array, referred to as an index. Thus, the data could be indexed using an integer ranging from one to the total number of elements in the array. Using the in-built randi function in MATLAB, random integers were first generated between one and the number of elements in the data array. Then, the data array was indexed using the randomly generated integers, in order to choose an element in the model to alter. For data arrays with more than one type of element (for example the selection of plates and rods in the model based on rod/plate ratio employed a data array containing both plates and rods), the randomly sampled index was tested first to make sure that the correct type of element was chosen from the data array. If the correct type of element was chosen, the inverse Monte Carlo iteration would continue. However, if the incorrect type of element was chosen, the iteration would be terminated and the simulation moved onto the next iteration, for which a new integer was randomly sampled. The in-built rng function in MATLAB was used to seed the random number generator based on the current time, thus mitigating the possibility of generating digital models that were identical.

1.3 C: Use of offset points to render trabecular thickness

An offset-point approach was used to add trabecular thickness (plate thickness and rod diameter) to the digital model, (Appendix Fig. 10). First, the shape center of each Voronoi cell face was determined by calculating the mean of the Voronoi face vertices. Then, nine vectors were drawn from every edge; three each in the direction of the three face’s shape centers (Appendix Fig. 10a, b). The vectors originated from the midpoint and both endpoints of each edge and terminated at a point between the edge and the face shape center. The points corresponding to the termination of the offset vectors are referred to as offset points, and the location of the point between the cell edge and face shape center was determined using a scale factor. For the offset vectors that originated from the endpoints of the cell edge, the scale factor was a fraction of the distance between the endpoint and the shape center. For the offset vectors that originated from the midpoint, the scale factor was between 0.3 and 0.5 times the length of the endpoint vectors.

Outline of the offset-point approach to render trabecular thickness in the model: a initial offset points are generated between a Voronoi face shape center and a corresponding Voronoi edge using offset vectors. b A total of nine offset vectors and offset points are generated at the intersection of three Voronoi faces. c The nine offset points are grouped into sets of three, forming the vertices a triangular region that was used to create additional offset points. The additional offset points were created by scaling offset vectors from the mean coordinate to the midpoint of the triangular sides by 1.5. d Connecting the additional offset points to the original offset points created hexagonal regions that allowed for a more natural rendering of the trabecula in the model. e Connecting the hexagonal regions with line segments between the eighteen offset points, twenty-four surfaces were generated to form a rod-like structure. f Rendering of a rod and plate in the model prior to triangular patching. If a face was assigned to be a trabecular plate, then all of the offset points in the interior of the plate were deleted. g The ends of rod were patched with triangular patches, along with junctions or joints that connected rods to other trabeculae in the model. h Triangular patches were used to cover the top and bottom face of plate and any openings along the sides of plates in the model

After creating the nine initial offset points, the offset points were grouped into three sets of offset points (Appendix Fig. 10c). One set of offset points was created from the offset vectors that originated from the midpoint, and the other two sets of points were created from the offset vectors that originated from the endpoints. At this point in the process, each set of three offset points formed a triangular region. Next, the mean coordinate of the vertices of each triangle was calculated, along with the midpoint of each side of the triangle. Additional offset points were created by drawing a vector from the mean coordinate of the triangle to the midpoint of each side and then scaling the vector by 1.5, so that the additional offset points were located outside of the triangular region. The generation of these additional offset points formed hexagonal regions (Appendix Fig. 10d). By connecting these regions with line segments between the eighteen offset points, twenty-four surfaces were generated to form a rod-like structure (Appendix Fig. 10e, f). For a Voronoi edge that was assigned to be a rod in the digital model, the ends of the rod, along with junctions or joints that connected the rod to other trabeculae in the model, were patched with triangular patches (Appendix Fig. 10g). On the other hand, if a face was assigned to be a trabecular plate in the digital model, all of the offset points in the interior of the plate would be deleted. In addition, triangular patches would be used to cover the top and bottom face of the plate and any openings along the sides of the plate (Appendix Fig. 10f, h).

The plate thickness and rod diameter of trabeculae in the digital model were determined based on the equivalent trabecular thickness of an ideal trabecular geometry. In more detail, the volume of a plate in the digital model was computed and then the plate was equated to a uniformly thick polyhedron with the same volume and the same face area. The thickness of this polyhedron represented the thickness of the plate in the model and was calculated as follows:

where \(t\) is the equivalent thickness of the trabecular plate, \(V\) is the volume of the plate, and \(A_{\text{c}}\) is the cross-sectional area of the face of the plate in the model.

Similarly, the diameter of a rod in the model was determined by computing the volume of the rod and then equating the rod to a cylinder with the same volume and the same length. The diameter of this cylinder represented the diameter of the rod in the model and was calculated as follows:

where \(d\) is the equivalent diameter of the trabecular rod, \(V\) is the volume of the rod, and \(L\) is the length of the rod in the model.

Since the plates and rods in the digital model are triangular surface meshes, the divergence theorem was used to compute the volume of the trabeculae in the model using a surface integral. The divergence theorem describes the relationship between a volume integral and surface integral, and the volume (\(V\)) of the trabeculae in the digital model was calculated as follows:

where \(\bar{F}\) is the vector [x, 0, 0], of which x is the x-coordinate of the centroid of the triangular surface, \(\hat{n}\) is the unit surface normal of the triangular surface, and \(\Delta S\) is the area of the triangular surface.

1.4 D: Pre-screening pilot convergence test

The pre-screening process developed in this study involved randomly selecting half of the Voronoi cell faces in the initial Voronoi tessellation model and assigning these faces as plates in the digital model, assigning the remaining Voronoi cell edges that were not associated with the selected faces as rods in the digital model, computing the total error sum of squares (\({\text{SSE}}_{\text{total}}\)) associated with the starting configuration of plates and rods in the model, and then iterating multiple times to achieve a starting configuration with a minimum \({\text{SSE}}_{\text{total}}\). In order to determine the optimum number of pre-screening iterations to minimize the \({\text{SSE}}_{\text{total}}\) of the starting configuration of plates and rods in the digital model, a pilot convergence test was performed. In the pilot convergence test, the minimum \({\text{SSE}}_{\text{total}}\) was determined for eight pre-screening iterations from 1 to 600,000, and each pre-screening process started with the same nominal initial Voronoi tessellation model. The procedure was repeated ten times for each of the eight pre-screening iterations, and the mean and standard deviation of the minimum \({\text{SSE}}_{\text{total}}\) were calculated (Appendix Fig. 11). The minimum \({\text{SSE}}_{\text{total}}\) appeared to converge between 300,000 and 600,000 iterations. The converged value for the minimum \({\text{SSE}}_{\text{total}}\) was roughly 17% less than the minimum error associated with no pre-screening process (1 pre-screening iteration). In addition, the converged minimum \({\text{SSE}}_{\text{total}}\) was approximately 25% less than the maximum error (at the 99% confidence bound), which is the largest \({\text{SSE}}_{\text{total}}\) that could be obtained if no pre-screening process was employed in the modeling framework. This pilot convergence test shows that the pre-screening process helps to reduce the \({\text{SSE}}_{\text{total}}\) of the starting configuration of plates and rods in the digital model, and based on this test, the number of pre-screening iterations was selected to be 600,000 for the models generated in this study.

Pilot convergence test for the pre-screening process, in which the minimum total error sum of squares (\({\text{SSE}}_{\text{total}}\)) was determined for eight pre-screening iteration from 1 to 600,000, and the procedure was repeated ten times for each of the eight pre-screening iterations in order to determine the mean (filled circles) and standard deviation (error bars represent ± one standard deviation) of the minimum \({\text{SSE}}_{\text{total}}\). The maximum error line represents the largest \({\text{SSE}}_{\text{total}}\) (at the 99% confidence bound) that could be obtained if no pre-screening process was employed in the modeling framework. The 99% confidence bound means that the probability of obtaining a larger \({\text{SSE}}_{\text{total}}\) than the maximum error line is 1%. Note: the 99% confidence bound of the maximum \({\text{SSE}}_{\text{total}}\) was estimated from 1000 Monte Carlo samples

Rights and permissions

About this article

Cite this article

Kirby, M., Morshed, A.H., Gomez, J. et al. Three-dimensional rendering of trabecular bone microarchitecture using a probabilistic approach. Biomech Model Mechanobiol 19, 1263–1281 (2020). https://doi.org/10.1007/s10237-020-01286-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-020-01286-8