Abstract

This study investigates the link between the mechanical properties of skin and its microstructural characteristics. Rat back skin samples from different locations, orientations, and sexes were collected and subjected to quasi-static uniaxial tensile tests. Stress–stretch behavior at low stress ranges and rupture data at high stress ranges were collected. The influence of location, orientation, and sex on skin mechanical properties was examined by comparing the mechanical parameters (i.e., initial slope, maximum slope, ultimate tensile strength, rupture stretch, and toughness) evaluated from the tensile testing data. Location and orientation were both found to have a significant effect on the mechanical properties. Collagen structural data (i.e., fiber orientation distribution, relative content, and fiber straightness) were evaluated using histology images. It was found that the rat lower (caudal) back had higher relative collagen content when compared to the upper (cranial) back. A microstructurally based constitutive model was proposed to describe the mechanical behavior of preconditioned rat back skin. The constitutive model incorporated the distribution of collagen fiber bundle orientations and relative collagen content measured from histology, and showed good agreement with the tensile test data. The influence of location and orientation was also evident in the optimized constitutive parameters. This study was a comprehensive investigation that combines skin mechanical behavior, micro-structure, and constitutive modeling.

Similar content being viewed by others

References

Andreassen T, Oxlund H (1987) The influence of experimental diabetes and insulin treatments on the biochemical properties of rat skin incisional wounds. Acta Chir Scand 153:405–409

Arun Gopinathan P, Kokila G, Jyothi M et al (2015) Study of collagen birefringence in different grades of oral squamous cell carcinoma using picrosirius red and polarized light microscopy. In: Scientifica. https://www.hindawi.com/journals/scientifica/2015/802980/abs/. Accessed 27 Sep 2017

Auriol F, Vaillant L, Machet L et al (1993) Effects of short-time hydration on skin extensibility. Acta Derm Venereol 73:344–347

Baek S, Gleason RL, Rajagopal KR, Humphrey JD (2007) Theory of small on large: potential utility in computations of fluid–solid interactions in arteries. Comput Methods Appl Mech Eng 196:3070–3078. https://doi.org/10.1016/j.cma.2006.06.018

Balli E, Comelekoglu U, Yalin E et al (2009) Exposure to gamma rays induces early alterations in skin in rodents: mechanical, biochemical and structural responses. Ecotoxicol Environ Saf 72:889–894

Bartell THMD, Mustoe TAMD (1989) Animal models of human tissue expansion. Plast Reconstr Surg 83:681–686

Bellini C, Ferruzzi J, Roccabianca S et al (2014) A microstructurally motivated model of arterial wall mechanics with mechanobiological implications. Ann Biomed Eng 42:488–502. https://doi.org/10.1007/s10439-013-0928-x

Billingham RE, Medawar PB (1952) The freezing, drying and storage of mammalian skin. J Exp Biol 29:454–468

Briggs R, Jund L (1944) Successful grafting of frozen and thawed mouse skin. Anat Rec 89:75–85. https://doi.org/10.1002/ar.1090890108

Byrne DJ, Hardy J, Wood R, Wood RAB et al (1991) Effect of fibrin glues on the mechanical properties of healing wounds. Br J Surg 78:841–843. https://doi.org/10.1002/bjs.1800780723

Delalleau A, Josse G, Lagarde J-M et al (2008) A nonlinear elastic behavior to identify the mechanical parameters of human skin in vivo. Skin Res Technol 14:152–164

Escoffier C, deRigal J, Rochefort A et al (1989) Age-related mechanical properties of human skin: an in vivo study. J Investig Dermatol 93:353–357

Ferruzzi J, Bersi MR, Humphrey JD (2013) Biomechanical phenotyping of central arteries in health and disease: advantages of and methods for murine models. Ann Biomed Eng 41:1311–1330. https://doi.org/10.1007/s10439-013-0799-1

Flynn C, Rubin MB, Nielsen P (2011) A model for the anisotropic response of fibrous soft tissues using six discrete fibre bundles. Int J Numer Methods Biomed Eng 27:1793–1811. https://doi.org/10.1002/cnm.1440

Foutz TL, Stone EA, Abrams CF Jr (1992) Effects of freezing on mechanical properties of rat skin. Am J Vet Res 53:788–792

Gasser TC, Ogden RW, Holzapfel GA (2006) Hyperelastic modelling of arterial layers with distributed collagen fibre orientations. J R Soc Interface 3:15–35. https://doi.org/10.1098/rsif.2005.0073

Groves RB, Coulman SA, Birchall JC, Evans SL (2013) An anisotropic, hyperelastic model for skin: experimental measurements, finite element modelling and identification of parameters for human and murine skin. J Mech Behav Biomed Mater 18:167–180. https://doi.org/10.1016/j.jmbbm.2012.10.021

Guan E, Smilow S, Rafailovich M, Sokolov J (2004) Determining the mechanical properties of rat skin with digital image speckle correlation. DRM 208:112–119. https://doi.org/10.1159/000076483

Haut RC (1989) The effects of orientation and location on the strength of dorsal rat skin in high and low speed tensile failure experiments. J Biomech Eng 111:136–140. https://doi.org/10.1115/1.3168354

Hoyt RH, Collins SM, Skorton DJ et al (1985) Assessment of fibrosis in infarcted human hearts by analysis of ultrasonic backscatter. Circulation 71:740–744. https://doi.org/10.1161/01.CIR.71.4.740

Jor JWY, Nash MP, Nielsen PMF, Hunter PJ (2011a) Estimating constitutive parameters of a structurally based constitutive relation for skin mechanics. Biomech Model Mechanobiol 10:767–778. https://doi.org/10.1007/s10237-010-0272-0

Jor JWY, Nielsen PMF, Nash MP, Hunter PJ (2011b) Modelling collagen fibre orientation in porcine skin based upon confocal laser scanning microscopy. Skin Res Technol 17:149–159. https://doi.org/10.1111/j.1600-0846.2011.00471.x

Karimi A, Navidbakhsh M, Haghighatnama M, Haghi AM (2015a) Determination of the axial and circumferential mechanical properties of the skin tissue using experimental testing and constitutive modeling. Comput Methods Biomech Biomed Eng 18:1768–1774. https://doi.org/10.1080/10255842.2014.961441

Karimi A, Rahmati SM, Navidbakhsh M (2015b) Mechanical characterization of the rat and mice skin tissues using histostructural and uniaxial data. Bioengineered 6:153–160. https://doi.org/10.1080/21655979.2015.1036202

Lanir Y (1979) A structural theory for the homogeneous biaxial stress–strain relationships in flat collagenous tissues. J Biomech 12:423–436. https://doi.org/10.1016/0021-9290(79)90027-7

Lanir YT (1983) Constitutive equations for fibrous connective tissues. J Biomech 16:1–12

Lanir Y, Fung YC (1974) Two-dimensional mechanical properties of rabbit skin-II. Experimental results. J Biomech 7:171IN9175–171IN174182

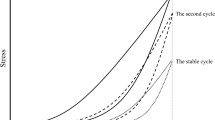

Liu Z, Yeung K (2008) The preconditioning and stress relaxation of skin tissue. J Biomed Pharm Eng 2:22–28

Luebberding S, Krueger N, Kerscher M (2014) Mechanical properties of human skin in vivo: a comparative evaluation in 300 men and women. Skin Res Technol 20:127–135. https://doi.org/10.1111/srt.12094

Marangoni RD, Glaser AA, Must JS et al (1966) Effect of storage and handling techniques on skin tissue properties. Ann N Y Acad Sci 136:441–453. https://doi.org/10.1111/j.1749-6632.1966.tb39679.x

Muñoz MJ, Bea JA, Rodríguez JF et al (2008) An experimental study of the mouse skin behaviour: damage and inelastic aspects. J Biomech 41:93–99. https://doi.org/10.1016/j.jbiomech.2007.07.013

Ní Annaidh A, Bruyère K, Destrade M et al (2012a) Characterization of the anisotropic mechanical properties of excised human skin. J Mech Behav Biomed Mater 5:139–148. https://doi.org/10.1016/j.jmbbm.2011.08.016

Ní Annaidh A, Bruyère K, Destrade M et al (2012b) Automated estimation of collagen fibre dispersion in the dermis and its contribution to the anisotropic behaviour of skin. Ann Biomed Eng 40:1666–1678. https://doi.org/10.1007/s10439-012-0542-3

Ottenio M, Tran D, Ní Annaidh A et al (2015) Strain rate and anisotropy effects on the tensile failure characteristics of human skin. J Mech Behav Biomed Mater 41:241–250. https://doi.org/10.1016/j.jmbbm.2014.10.006

Ranu HS (1979) The mechanical and structural response of skin to irradiation. J Biomech 12:601–608. https://doi.org/10.1016/0021-9290(79)90080-0

Ranu HS (1991) Effects of radiotherapy on the mechanical properties of human skin. IEEE Eng Med Biol Mag 10:55–57. https://doi.org/10.1109/51.82010

Ranu HS, Burlin TE, Hutton WC (1975) The effects of X-irradiation on the mechanical properties of skin. Phys Med Biol 20:96

Rezakhaniha R, Agianniotis A, Schrauwen JTC et al (2012) Experimental investigation of collagen waviness and orientation in the arterial adventitia using confocal laser scanning microscopy. Biomech Model Mechanobiol 11:461–473. https://doi.org/10.1007/s10237-011-0325-z

Rich L, Whittaker P (2005) Collagen and picrosirius red staining: a polarized light assessment of fibrillar hue and spatial distribution. Braz J Morphol Sci 22:97–104

Takeuchi H, Mano Y, Terasaka S et al (2011) Usefulness of rat skin as a substitute for human skin in the in vitro skin permeation study. Exp Anim 60:373–384. https://doi.org/10.1538/expanim.60.373

Vogel HG (1974) Correlation between tensile strength and collagen content in rat skin. Effect of age and cortisol treatment. Connect Tissue Res 2:177–182. https://doi.org/10.3109/03008207409152242

Vogel HG (1981) Directional variations of mechanical parameter in rat skin depending on maturation and age. J Investig Dermatol 76:493–497. https://doi.org/10.1111/1523-1747.ep12521202

Vogel HG, Denkel K (1985) In vivo recovery of mechanical properties in rat skin after repeated strain. Arch Dermatol Res 277:484–488. https://doi.org/10.1007/BF00510067

Vogel HG, Hilgner W (1979) The “step phenomenon” as observed in animal skin. J Biomech 12:75–81

Webster JP (1944) Refrigerated skin grafts. Ann Surg 120:431–448

Wei JCJ, Edwards GA, Martin DJ et al (2017) Allometric scaling of skin thickness, elasticity, viscoelasticity to mass for micro-medical device translation: from mice, rats, rabbits, pigs to humans. Sci Rep 7:15885. https://doi.org/10.1038/s41598-017-15830-7

Xu F, Lu T (2011) Introduction to skin biothermomechanics and thermal pain. Springer, Berlin

You C, Wang X, Zheng Y, Han C (2013) Three types of dermal grafts in rats: the importance of mechanical property and structural design. Biomed Eng 12:125. https://doi.org/10.1186/1475-925X-12-125

Zeinali-Davarani S, Wang Y, Chow M-J et al (2015) Contribution of collagen fiber undulation to regional biomechanical properties along porcine thoracic aorta. J Biomech Eng 137:051001. https://doi.org/10.1115/1.4029637

Zeng Y, Liu Y, Xu C et al (2004) Biomechanical properties of skin in vitro for different expansion methods. Clin Biomech 19:853–857

Acknowledgements

We gratefully acknowledge Christina Chan, Ph.D. for providing the rat skin tissue.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Influence of storage condition on skin mechanical properties

To investigate the influence of storage condition on skin mechanical properties, three different storage protocols were developed as follows, Protocol I: samples were stored at 4 °C in Hank’s Balance Salted Solution (HBSS) for 24 h before testing. Protocol II: samples were flash frozen in isopentane that was cooled down by dry ice (− 78.5 °C). The flash frozen samples were then stored in a − 80 °C chamber for up to 2 weeks, and thawed at 4 °C for 6 h before testing. Protocol III: flash freezing and storage temperature were the same as Protocol II, but samples were thawed at 4 °C for 24 h before testing. Control: samples were tested fresh, within 2 h of excision. Skin samples obtained from each animal in Group I were randomized into the four groups (three storage protocols plus control), while skin samples obtained from animals in Group II were stored using Protocol II.

After the mechanical testing, a one-way ANOVA was carried out to examine the influence of storage condition on skin mechanical parameters. While the averaged stress–stretch behavior difference between the control group and each storage protocol was evaluated using normalized root-mean-square deviation (RMSD), which was calculated as

where \(\lambda^{\text{prtcl}}\) and \(\lambda^{\text{cntrl}}\) represented stretch ratios of a sample from a storage protocol and a control sample, respectively, at 20 (i.e., n = 20) different evenly spaced stress values along the stress–stretch curve.

The five mechanical parameters of Group I samples were evaluated and grouped based on storage protocol (see Fig. 8). The storage protocol did not have a significant effect on initial slope, maximum slope, UTS, rupture strain, or toughness (p > 0.05). Normalized RMSD between the control group (fresh samples) and each of the other three storage protocols were calculated to further compare the influence of the storage protocol on the nonlinear mechanical behavior of skin, see Table 2. Results showed that Protocol II had the lowest total normalized RMSD (7.11%), followed by Protocol III (13.75%) and Protocol I (16.97%).

Inflluence of storage condition on initial slope, maximum slope, UTS, rupture strain, and toughness. Values shown in the bar graph are means and standard deviations. Values shown below each bar graph are p values of one-way ANOVA comparing the mechanical parameter difference between four different storage conditions

Since the influence of different storage conditions on the mechanical properties of skin was not significant, samples from Group I and Group II animals were put together to study the influence of location, orientation, and sex on skin mechanical properties.

Appendix 2: Parameter sensitivity

Best-fit values for the four constitutive parameters (i.e., \(c^{gm}\), \(c_{1}\), \(c_{2}\), and \(G_{q}\)) were obtained from the estimation process. We, then, investigated the sensitivity of the model to each one of these parameter for one representative sample. Starting from the best-fit constitutive parameters of the representative sample UL22, we changed the value of one parameter at a time, namely for the constitutive parameters \(c^{gm}\), \(c_{1}\), \(c_{2}\) in the range 20–180% of the reference value, and the kinematic parameter \(G_{q}\) in the range 0.92–1. We, then, estimated the theoretical stress–stretch curve employing each new set of modified parameters, chosen considering one parameter varying from the reference value, as described, and all the other parameters set to reference values. Finally, the difference between the curves generated with the modified parameter and the original curve is measured using normalized RMSD, described as

where \(\lambda_{\text{ref}}\) and \(\lambda_{\bmod }\) represent the stretch values at a certain stress level in the curve generated with reference parameter values and the curve generated with one modified parameter, respectively. Stretch values at 30 evenly spaced stress values were considered, i.e., \(N = 30.\)

The stress–stretch curve generated by the constitutive model, using reference parameter values for the representative sample (i.e., \(c^{gm} = 0.44 \,{\text{MPa}}\), \(c_{1} = 59 \,{\text{MPa}}\), \(c_{2} = 32\), \(G_{q} = 0.96\)) are shown as thick dashed lines in Fig. 9a–e. The stress–stretch curves generated by the constitutive model with one modified parameter, using values that range from 20 to 180% (or 0.92–1) of the reference value, are shown as solid lines in lighter to darker gray in Fig. 9a–e. The normalized RMSDs, as described by Eq. (6), are shown in Fig. 10a–d. When \(c^{gm}\) was varied, as shown in Fig. 9a, the change of the stress–stretch is very small, suggesting the model is not sensitive to this parameter. However, when only the portion of the curve for stretches < 1.02 is considered, the normalized RMSD could reach as high as 46.7%, as shown in Figs. 9b and 10a, suggesting the low stretch potion of the curve is significantly sensitive to \(c^{gm}\). When \(c_{1}\), \(c_{2}\), and \(G_{q}\) were varied, as shown in Figs. 9c–e and 10b–d, the normalized RMSD could reach as high as 27.4%, 19.0%, and 167.4%, respectively. This suggest that the model is significantly sensitive to these parameters, especially \(G_{q}\). It is also interesting to notice that since \(c_{2}\) and \(G_{q}\) exist in the exponential term of the stress–stretch equation, the normalized RMSD is not symmetrical with respect to the reference values, compared to the symmetrical changes showed for \(c^{gm}\) and \(c_{1}\).

Simulated stress–stretch curve when the value of a parameter is changed for the reference sample. For a\(c^{gm}\), c\(c_{1}\), and d\(c_{2}\), the parameter values is changed from 20 to 180% of the reference value (i.e., \(c^{gm} = 0.44\,{\text{MPa}}\), \(c_{1} = 59\,{\text{MPa}}\), \(c_{2} = 32\)). For e\(G_{q}\) (reference value \(G_{q} = 0.96\)), the parameter value is changed from 0.92 to 1. The simulated stress–stretch curves between stretch range 1–1.02 when \(c_{gm}\) is changed is shown in b

Normalized RMSD between the simulated stress–stretch curve with one altered parameter value and the simulated stress–stretch curve with reference parameter values. For a\(c^{gm}\) (between stretch range 1–1.02), b\(c_{1}\), and c\(c_{2}\), the parameter values is changed from 20 to 180% of the reference value (i.e., \(c^{gm} = 0.44 \,{\text{MPa}}\), \(c_{1} = 59 \,{\text{MPa}}\), \(c_{2} = 32\)). For d\(G_{q}\) (reference value \(G_{q} = 0.96\)), the parameter value is changed from 0.92 to 1

Appendix 3: Location, orientation and sex effect

Mechanical parameters evaluated from rupture stress–stretch curves were grouped based on three different factors, i.e., location (upper vs. lower back), orientation (axial vs. transverse direction), and sex (male vs. female). Group median and quartiles based on different factors are shown in box plot in Fig. 11.

Influence of location, orientation, and sex on a initial slope, b maximum slope, c rupture strain, d UTS, and e toughness. Quartiles of each parameter based on the grouping factor were shown in the figure. On each box, the central mark indicates the median, and the bottom and top edges of the box indicate the 25th and 75th percentile, respectively. The Whiskers extent to the most extreme data points not considered outliers, and the outliers are plotted individually using the ‘+’ symbol. P values of the three-way ANOVA are shown below the bar graph for comparison within each factor, i.e., upper versus lower, axial versus transverse, male versus female. Statistical significance is marked by the asterisk (p < 0.05)

Rights and permissions

About this article

Cite this article

Chen, S., Ní Annaidh, A. & Roccabianca, S. A microstructurally inspired constitutive model for skin mechanics. Biomech Model Mechanobiol 19, 275–289 (2020). https://doi.org/10.1007/s10237-019-01210-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-019-01210-9