Abstract

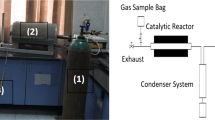

For thermal recycle by wasted plastics coated around electric cables, ignition and combustion experiments of the pulverized samples were carried out, using two types of electrically heated drop tube furnace, in which the particles are pulsatively fed and continuously fed, respectively. The ignition phenomenon was defined as occurrence of luminous emission from a cloud of the particles fed in the former furnace. The wasted plastics coated around the electric cables mainly make of polyethylene with a little amount of carbon particles. The ignition characteristics of the pulverized plastic samples as well as graphite particles as a reference sample were studied, changing the particle diameters and the furnace wall temperatures. In the electrically heated drop tube furnace with the continuous feeding system, the wall temperature and stoichiometric combustion air ratio were varied to elucidate the fundamental combustion characteristics. As a result, the ignition temperature depended on the particle diameter. The plastics with the particle diameter ranged from 150 to 300 µm could ignite at the lowest furnace temperature. From the continuous combustion tests, CO and lower molecule hydrocarbons like CH4, C2H2 and C2H4 were produced in the upper region of furnace. Finally, all of them gradually burned out.

Similar content being viewed by others

References

Plastics products, plastics waste and resource recovery (2015) PWMI newsletter. http://www.pwmi.or.jp/ei/siryo/ei/ei_pdf/ei44.pdf. Accessed 15 Apr 2016

Lazarevic D, Aoustin E, Buclet N, Brandt N (2010) Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resour Conserv Recycl 55(2):246–259. doi:10.1016/j.resconrec.2010.09.014

Hopewell J, Dvorak R, Kosior E (2009) Plastics recycling: challenges and opportunities. Phil Trans R Soc B 364:2115–2126. doi:10.1098/rstb.2008.0311

Murata H, Sato K, Teshima H (1981) Thermal degradation of high density polyethylene by using a continuous flow stirred tank reactor (in Japanese). Kagaku Kogaku Ronbunshu 7(1):64–70

Koo JK, Kim SW, Seo YH (1991) Characterization of aromatic hydrocarbon formation from pyrolysis of polyethylene–polystyrene mixtures. Resour Conserv Recycl 5(4):365–382. doi:10.1016/0921-3449(91)90013-E

Scott DS, Czernik SR, Piskorz J, Radlein DStAG (1990) Fast pyrolysis of plastic wastes. Energy Fuels 4(4):407–411. doi:10.1021/ef00022a013

Murata K, Makino T (1973) Thermal degradation of high density polyethylene (in Japanese). Nippon Kagaku Kaishi 12:2414–2420

Namie S, Yamanouchi H (1988) The combustion of waste FRP with a fluidized bed furnace (in Japanese). Trans JSME Ser B 54(505):2605–2610

Xiao G, Ni MJ, Chi Y, Cen KF (2008) Low-temperature gasification of waste tire in a fluidized bed. Energ Convers Manag 49(8):2078–2082. doi:10.1016/j.enconman.2008.02.016

Phanphanich M, Mani S (2011) Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour Technol 102(2):1246–1253. doi:10.1016/j.biortech.2010.08.028

Courtemanchea B, Levendis YANG (1998) A laboratory study on the NO, NO2, SO2, CO and CO2 emissions from the combustion of pulverized coal, municipal waste plastics and tires. Fuel 77(3):183–196. doi:10.1016/S0016-2361(97)00191-9

Simoneit BRT, Medeiros PM, Didyk BM (2005) Combustion products of plastics as indicators for refuse burning in the atmosphere. Environ Sci Technol 39(18):6961–6970. doi:10.1021/es050767x

Unger N, Gough O (2008) Life cycle considerations about optic fibre cable and copper cable systems: a case study. J Clean Prod 16(14):1517–1525. doi:10.1016/j.jclepro.2007.08.016

Sueyoshi H, Kitaoka Y (1972) Make fuel from plastic wastes. Hydrocarbon Process 51:161–163

Khait K, Torkelson JM (1999) Solid-state shear pulverization of plastics: a green recycling process. Polyplast Tech Eng 38(3):445–457. doi:10.1080/03602559909351592

Liang M, Lu C, Huang Y, Zhang C (2007) Morphological and structural development of poly(ether ether ketone) during mechanical pulverization. J Appl Polym Sci 106(6):3895–3902. doi:10.1002/app.26916

Jonna S, Lyons J (2005) Processing and properties of cryogenically milled post-consumer mixed plastic waste. Polym Test 24(4):428–434. doi:10.1016/j.polymertesting.2005.01.009

Yu J, Lucas JA, Wall TF (2007) Formation of the structure of chars during devolatilization of pulverized coal and its thermoproperties: a review. Prog Energy Combust Sci 33(2):135–170. doi:10.1016/j.pecs.2006.07.003

Buhre BJP, Elliott LK, Sheng CD, Gupta RP, Wall TF (2005) Oxy-fuel combustion technology for coal-fired power generation. Prog Energy Combust Sci 31(4):283–307. doi:10.1016/j.pecs.2005.07.001

Smith IW (1982) The combustion rates of coal chars: a review. Nineteenth symposium (international) on combustion. Combust Inst 19(1):1045–1065. doi:10.1016/S0082-0784(82)80281-6

Damle AS, Ensor DS, Ranade MB (1981) Coal combustion aerosol formation mechanisms: a review. Aerosol Sci Technol 1(1):119–133. doi:10.1080/02786828208958582

Su S, Pohl JH, Holcombe D, Hart JA (2001) Techniques to determine ignition, flame stability and burnout of blended coals in p.f. power station boilers. Prog Energy Combust Sci 27(1):75–98. doi:10.1016/S0360-1285(00)00006-X

International Labor Organization (ILO) (2015) The International Chemical Safety Cards (ICSC) database. http://www.ilo.org/dyn/icsc/showcard.home. Accessed 10 May 2016

Pinto F, Costa P, Gulyurtlu I, Cabrita I (1999) Pyrolysis of plastic wastes. 1. Effect of plastic waste composition on product yield. J Anal Appl Pyrolysis 51(1–2):39–55. doi:10.1016/S0165-2370(99)00007-8

Kiran N, Ekinci E, Snape CE (2000) Recyling of plastic wastes via pyrolysis. Resour Conserv Recyl 29(4):273–283. doi:10.1016/S0921-3449(00)00052-5

Achilias DS, Roupakias C, Megalokonomos P, Lappas AA, Antonakou EV (2007) Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J Hazard Mater 149(3):536–542. doi:10.1016/j.jhazmat.2007.06.076

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nunome, Y., Matsumoto, H., Nedjalkov, I. et al. Combustion behaviors of wasted plastics coated around electric cables in electrically heated drop tube furnaces. J Mater Cycles Waste Manag 20, 543–551 (2018). https://doi.org/10.1007/s10163-017-0618-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-017-0618-0