Abstract

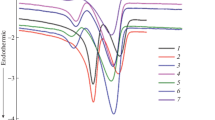

A series of cross-linked poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/octavinyloctasilasesquioxane (PHBV/OVS) composites were obtained by a simple melt reactive processing technique. Dicumyl peroxide (DCP) and OVS were employed as a free radical initiator and a cross-linking agent, respectively. The chemical structure of these produced composites were identified by 1H/13C/29Si-nuclear magnetic resonance spectroscopy (1H/13C/29Si-NMR) and Fourier transform infrared spectroscopy (FTIR). The melting behavior, non-isothermal crystallization, spherulite morphology and thermal stability property of PHBV/OVS composites were also investigated. The nucleation behaviors and crystallization rate of PHBV/OVS were significantly enhanced with the formation of cross-linked networks with different side-chains and cross-linking points. The red shift of crystalline peak temperature with addition of a small amount of OVS content evidenced the higher crystalline ability compared with the neat PHBV. However there was a threshold content, beyond which the crystallization rate weakened again. Additionally, the cross-linked structure of PHBV/OVS composites could be adjusted by changing the amount of OVS.

Similar content being viewed by others

References

Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2013, 38(3), 536–583

Yang, W. B.; Zhang, L.; Guo, Y. L.; Jiang, Z. N.; He, F. F.; Xie, C. Q.; Fan, J. H.; Wu, J. Y.; Zhang, K. Novel segregated-structure phase change materials composed of paraffin@ graphene microencapsules with high latent heat and thermal conductivity. J. Mater. Sci. 2018, 53(4), 2566–2575

Wang, H.; Zhao, L.; Song, G. L.; Tang, G. Y.; Shi, X. H. Organic-inorganic hybrid shell microencapsulated phase change materials prepared from SiO2/TiC-stabilized pickering emulsion polymerization. Sol. Energ. Mater. Sol. C 2018, 175, 102–110

Iwata, T.; Aoyagi, Y.; Fujita, M.; Yamane, H.; Doi, Y.; Suzuki, Y.; Takeuchi, A.; Uesugi, K. Processing of a strong biodegradable poly[(,R)-3-hydroxybutyrate] fiber and a new fiber structure revealed by micro-beam X-Ray diffraction with synchrotron radiation. Macromol. Rapid Commun. 2004, 25(11), 1100–1104

Chen, Z.; Xiang, H.; Hu, Z.; Ni, Z.; Zhu, M. Enhanced mechanical properties of melt-spun bio-based PHBV fibers: effect of heterogeneous nucleation and drawing process. Acta Polymerica Sinica (in Chinese) 2017, (7), 1121–1129

Diez-Pascual, A. M.; Diez-Vicente, A. L. ZnO-reinforced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bionanocomposites with antimicrobial function for food packaging. ACS Appl. Mater. Interfaces 2014, 6(12), 9822–9834

Wang, Y. Y.; Lu, L. X.; Shi, J. C.; Wang, H. F.; Xiao, Z. D.; Huang, N. P. Introducing RGD peptides on PHBV films through PEG-containing cross-linkers to improve the biocompatibility. Biomacromolecules 2011, 12(3), 551–559

Josefine Fischer, J.; Aoyagi, Y.; Enoki, M.; Doi, Y.; Iwata, T. Mechanical properties and enzymatic degradation of poly([,R]-3-hydroxybutyrate-co-[ ]-3-hydroxyhexanoate) uniaxially cold-drawn films. Polym. Degrad. Stab. 2004, 83(3), 453–460

Lu, S. F.; Shen, T. W.; Xing, J. W.; Song, Q. W.; Shao, J. F.; Zhang, J.; Xin, C. Preparation and characterization of crosslinked polyurethane shell microencapsulated phase change materials by interfacial polymerization. Mater. Lett. 2018, 211, 36–39

Xiang, H. X.; Wang, S. C.; Wang, R. L.; Zhou, Z.; Peng, C.; Zhu, M. F. Synthesis and characterization of an environmentally friendly PHBV/PEG copolymer network as a phase change material. Sci. China Chem. 2013, 56(6), 716–723

Xiang, H. X.; Wen, X. S.; Miu, X. H.; Li, Y.; Zhou, Z.; Zhu, M. F. Thermal depolymerization mechanisms of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Prog. Nat. Sci-Mater. 2016, 26(1), 58–64

Ye, H. M.; Li, H.; Yang, Y. P. Crystallization behavior and phase transition of poly(,R-3-hydroxydecanoate). Colloid Polym. Sci. 2016, 294(4), 795–799

Wang, S.; Chen, W.; Xiang, H.; Yang, J.; Zhou, Z.; Zhu, M. Modification and potential application of short-chain-length polyhydroxyalkanoate (SCL-PHA). Polymers 2016, 8(8), 273

Nocita, D.; Forte, G.; Drakopoulos, S. X.; Visco, A.; Gianporcaro, A.; Ronca, S. Processing and characterization of bio-polyester reactive blends: From thermoplastic blends to cross-linked networks. Polymer 2017, 132, 252–263

Bian, Y. J.; Han, C. Y.; Han, L. J.; Lin, H. J.; Zhang, H. L.; Bian, J. J.; Dong, L. S. Toughening mechanism behind intriguing stress-strain curves in tensile tests of highly enhanced compatibilization of biodegradable poly(lactic acid)/poly(3-hydroxybutyrate-co-4-hydroxybutyrate) blends. RSC Adv. 2014, 4(79), 41722–41733

Wu, N. J.; Zhang, H.; Fu, G. L. Super-tough poly(lactide) thermoplastic vulcanizates based on modified natural rubber. ACS Sustain. Chem. Engineer. 2017, 5(1), 78–84

You, J.; Yu, W.; Zhou, C. Accelerated crystallization of poly(lactic acid): synergistic effect of poly(ethylene glycol), dibenzylidene sorbitol, and long-chain branching. Ind. Engineer. Chem. Res. 2014, 53(3), 1097–1107

Bian, Y. J.; Han, L. J.; Han, C. Y.; Lin, H. J.; Zhang, H. L.; Bian, J. J.; Dong, L. S. Intriguing crystallization behavior and rheological properties of radical-based crosslinked biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate). CrystEngComm, 2014, 16(13), 2702–2714

Pathaweeisariyakul, T.; Narkchamnan, K.; Thitisak, B.; Rungswang, W.; Yau, W. W. An alternative method for long chain branching determination by triple-detector gel permeation chromatography. Polymer 2016, 107, 122–129

Xiang, H. X.; Chen, W.; Chen, Z. Y.; Sun, B.; Zhu, M. F. Significant accelerated crystallization of long chain branched poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with high nucleation temperature under fast cooling rate. Compos. Sci. Technol. 2017, 142, 207–213

Wang, J.; Li, B.; Wang, X.; Yang, F.; Shen, H.; Wu, D. Morphological evolution of self-assembled structures induced by the molecular architecture of supra-amphiphiles. Langmuir 2016, 32(51), 13706–13715

Zhang, L.; Tang, H.; Hou, G.; Shen, Y.; Deng, F. The domain structure and mobility of semi-crystalline poly (3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate): A solid-state NMR study. Polymer 2007, 48(10), 2928–2938

Xiang, H. X.; Chen, S. H.; Cheng, Y. H.; Zhou, Z.; Zhu, M. F. Structural characteristics and enhanced mechanical and thermal properties of full biodegradable tea polyphenol/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) composite films. eXPRESS Polym. Lett. 2013, 7(9), 778–786

Xu, H.; Yang, B.; Wang, J.; Guang, S.; Li, C. Preparation, thermal properties, and Tg increase mechanism of poly(acetoxystyrene-co-octavinyl-polyhedral oligomeric silsesquioxane) hybrid nanocomposites. Macromolecules 2005, 38(25), 10455–10460

Zhang, Y.; Wang, C. L.; Du, H. N.; Li, X. P.; Mi, D. S.; Zhang, X. W.; Wang, T.; Zhang, J. Promoting crystallization of polylactide by the formation of crosslinking bundles. Mater. Lett. 2014, 117, 171–174

Ma, P. M.; Cai, X. X.; Wang, W.; Duan, F.; Shi, D. J.; Lemstra, P. J. Crystallization behavior of partially crosslinked poly(beta-hydroxyalkonates)/ poly(butylene succinate) blends. J. Appl. Polym. Sci. 2014, 131(21), 41020

Li, S. Z.; Xiao, M. M.; Wei, D. F.; Xiao, H. N.; Hu, F. Z.; Zheng, A. N. The melt grafting preparation and rheological characterization of long chain branching polypropylene. Polymer 2009, 50(25), 6121–6128

Acknowledgments

The authors gratefully acknowledge the support of the National Natural Science Foundation of China (No. 51603033), the Fundamental Research Funds for the Central Universities (Nos. 2232018A3-01 and 2232018D3-03), the Program for Innovative Research Team in University of Ministry of Education of China (No. IRT16R13) and the Open Foundation of Key Laboratory of Advanced Textile Materials and Manufacturing Technology (Zhejiang Sci-Tech University), Education Ministry of China (No. 2017001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, HX., Zabihi, F., Zhang, XZ. et al. The Crystallization, Melting Behaviors and Thermal Stability of Cross-linked Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Octavinyloctasilasesquioxane. Chin J Polym Sci 36, 1353–1360 (2018). https://doi.org/10.1007/s10118-018-2157-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-018-2157-0