Abstract

Hyper-crosslinked polymers (HCPs) are promising materials for gas capture and storage because of their low cost and easy preparation. In this work, we report the massive preparation of coumarone-indene resin-based hyper-crosslinked polymers via one-step Friedel-Crafts alkylation. Low-cost coumarone-indene resin serves as the new building block and chloroform is employed as both solvent and external crosslinker. A maximum surface area of 966 m2·g−1 is achieved, which is comparable with that of previously-reported coal tar-based porous organic polymers. Most importantly, a large number of heteroatoms including inherent oxygen atoms and introduced chlorine atoms in obtianed HCPs further enhance the interaction between specific sorbate molecule and adsorbent. Therefore, optimal structural and chemical property endow the new coumarone-indene resin-based HCPs with decent gas storage capacity (14.60 wt% at 273 K and 0.1 MPa for CO2; 1.18 wt% at 77.3 K and 0.1 MPa for H2). These results demonstrate that new HCPs are potential candidates for applications in CO2 and H2 capture.

Similar content being viewed by others

References

Xu, F.; Tang, Z.; Huang, S.; Chen, L.; Liang, Y.; Mai, W.; Zhong, H.; Fu, R.; Wu, D. Facile synthesis of ultrahigh-surface-area hollow carbon nanospheres for enhanced adsorption and energy storage. Nat. Commun. 2015, 6, 7221.

Gu, C.; Huang, N.; Gao, J.; Xu, F.; Xu, Y.; Jiang, D. Controlled synthesis of conjugated microporous polymer films: versatile platforms for highly sensitive and label-free chemo-and biosensing. Angew. Chem. Int. Ed. 2014, 53(19), 4850–4855.

Gu, C.; Chen, Y.; Zhang, Z.; Xue, S.; Sun, S.; Zhang, K.; Zhong, C.; Zhang, H.; Pan, Y.; Lv, Y.; Yang, Y.; Li, F.; Zhang, S.; Huang, F.; Ma, Y. Electrochemical route to fabricate film-like conjugated microporous polymers and application for organic electronics. Adv. Mater. 2013, 25(25), 3443–3448.

Yuan, S.; Dorney, B.; White, D.; Kirklin, S.; Zapol, P.; Yu, L.; Liu, D. J. Microporous polyphenylenes with tunable pore size for hydrogen storage. Chem. Commun. 2010, 46(25), 4547–4549.

Bezzu, C. G.; Carta, M.; Tonkins, A.; Jansen, J. C.; Bernardo, P.; Bazzarelli, F.; McKeown, N. B. A spirobifluorene-based polymer of intrinsic microporosity with improved performance for gas separation. Adv. Mater. 2012, 24(44), 5930.

McKeown, N. B.; Budd, P. M. Polymers of intrinsic microporosity (PIMs): organic materials for membrane separations, heterogeneous catalysis and hydrogen storage. Chem. Soc. Rev. 2006, 35(8), 675–683.

Jiang, J. X.; Su, F.; Trewin, A.; Wood, C. D.; Campbell, N. L.; Niu, H.; Dickinson, C.; Ganin, A. Y.; Rosseinsky, M. J.; Khimyak, Y. Z.; Cooper, A. I. Conjugated microporous poly(aryleneethynylene) networks. Angew. Chem. Int. Ed. 2007, 46(45), 8574–8578.

Ding, S. Y.; Wang, W. Covalent organic frameworks (COFs): from design to applications. Chem. Soc. Rev. 2013, 42(2), 548–568.

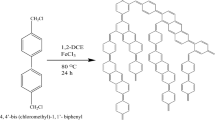

Li, B. Y.; Gong, R. N.; Wang, W.; Huang, X.; Zhang, W.; Li, H. M.; Hu, C. X.; Tan, B. E. A new strategy to microporous polymers: knitting rigid aromatic building blocks by external cross-linker. Macromolecules 2011, 44(8), 2410–2414.

Ren, S. J.; Bojdys, M. J.; Dawson, R.; Laybourn, A.; Khimyak, Y. Z.; Adams, D. J.; Cooper, A. I. Porous, Fluorescent, Covalent triazine-based frameworks via room-temperature and microwave-assisted synthesis. Adv. Mater. 2012, 24(17), 2357–2361.

Tan, L.; Tan, B. Hypercrosslinked porous polymer materials: design, synthesis, and applications. Chem. Soc. Rev. 2017, 46(11), 3322–3356.

Li, L. N.; Ren, H.; Yuan, Y.; Yu, G. L.; Zhu, G. S. Construction and adsorption properties of porous aromatic frameworks via AlCl3-triggered coupling polymerization. J. Mater. Chem. A 2014, 2(29), 11091–11098.

Xu, Y. H.; Jin, S. B.; Xu, H.; Nagai, A.; Jiang, D. L. Conjugated microporous polymers: design, synthesis and application. Chem. Soc. Rev. 2013, 42(20), 8012–8031.

Ghanem, B. S.; Msayib, K. J.; McKeown, N. B.; Harris, K. D. M.; Pan, Z.; Budd, P. M.; Butler, A.; Selbie, J.; Book, D.; Walton, A. A triptycene-based polymer of intrinsic microposity that displays enhanced surface area and hydrogen adsorption. Chem. Commun. 2007, (1), 67–69.

Wang, S. L.; Tan, L. X.; Zhang, C. X.; Hussain, I.; Tan, B. E. Novel POSS-based organic-inorganic hybrid porous materials by low cost strategies. J. Mater. Chem. A 2015, 3(12), 6542–6548.

Tian, Z. H.; Huang, J. J.; Zhang, Z. L.; Shao, G. L.; Liu, A.; Yuan, S. G. Organic-inorganic hybrid microporous polymers based on octaphenylcyclotetrasiloxane: synthesis, carbonization and adsorption for CO2. Microporous Mesoporous Mater. 2016, 234, 130–136.

Zhu, J. H.; Chen, Q.; Sui, Z. Y.; Pan, L.; Yu, J. G.; Han, B. H. Preparation and adsorption performance of cross-linked porous polycarbazoles. J. Mater. Chem. A 2014, 2(38), 16181–16189.

Msayib, K. J.; McKeown, N. B. Inexpensive polyphenylene network polymers with enhanced microporosity. J. Mater. Chem. A 2016, 4(26), 10110–10113.

Meng, Q. B.; Weber, J. Lignin-based microporous materials as selective adsorbents for carbon dioxide separation. ChemSusChem 2014, 7(12), 3312–3318.

Modak, A.; Maegawa, Y.; Goto, Y.; Inagaki, S. Synthesis of 9,9′-spirobifluorene-based conjugated microporous polymers by FeCl3-mediated polymerization. Polym. Chem. 2016, 7(6), 1290–1296.

Li, W.; Zhang, A.; Gao, H.; Chen, M.; Liu, A.; Bai, H.; Li, L. Massive preparation of pitch-based organic microporous polymers for gas storage. Chem. Commun. 2016, 52(13), 2780–2783.

Gao, H.; Ding, L.; Bai, H.; Li, L. Microporous organic polymers based on hyper-crosslinked coal tar: preparation and application for gas adsorption. ChemSusChem 2017, 10(3), 618–623.

Li, B. Y.; Guan, Z. H.; Yang, X. J.; Wang, W. D.; Wang, W.; Hussain, I.; Song, K. P.; Tan, B. E.; Li, T. Multifunctional microporous organic polymers. J. Mater. Chem. A 2014, 2(30), 11930–11939.

Gao, H.; Ding, L.; Bai, H.; Liu, A. H.; Li, S. Z.; Li, L. Pitchbased hyper-cross-linked polymers with high performance for gas adsorption. J. Mater. Chem. A 2016, 4(42), 16490–16498.

Pan, L.; Chen, Q.; Zhu, J. H.; Yu, J. G.; He, Y. J.; Han, B. H. Hypercrosslinked porous polycarbazoles via one-step oxidative coupling reaction and Friedel-Crafts alkylation. Polym. Chem. 2015, 6(13), 2478–2487.

Ben, T.; Li, Y.; Zhu, L.; Zhang, D.; Cao, D.; Xiang, Z.; Yao, X.; Qiu, S. Selective adsorption of carbon dioxide by carbonized porous aromatic framework (PAF). Energy Environ. Sci. 2012, 5(8), 8370–8376.

Zhang, D.; Tao, L. M.; Wang, Q. H.; Wang, T. M. A facile synthesis of cost-effective triphenylamine-containing porous organic polymers using different crosslinkers. Polymer 2016, 82, 114–120.

Luo, Y. L.; Zhang, S. C.; Ma, Y. X.; Wang, W.; Tan, B. Microporous organic polymers synthesized by self-condensation of aromatic hydroxymethyl monomers. Polym. Chem. 2013, 4(4), 1126–1131.

Gao, H.; Ding, L.; Li, W. Q.; Ma, G. F.; Bai, H.; Li, L. Hypercross-linked organic microporous polymers based on alternating copolymerization of bismaleimide. ACS Macro Lett. 2016, 5(3), 377–381.

Kou, J.; Sun, L. B. Fabrication of nitrogen-doped porous carbons for highly efficient CO2 capture: rational choice of a polymer precursor. J. Mater. Chem. A 2016, 4(44), 17299–17307.

Rabbani, M. G.; El-Kaderi, H. M. Template-free Synthesis of a highly porous benzimidazole-linked polymer for CO2 capture and H2 storage. Chem. Mater. 2011, 23(7), 1650–1653.

Martin, C. F.; Stoeckel, E.; Clowes, R.; Adams, D. J.; Cooper, A. I.; Pis, J. J.; Rubiera, F.; Pevida, C. Hypercrosslinked organic polymer networks as potential adsorbents for precombustion CO2 capture. J. Mater. Chem. 2011, 21(14), 5475–5483.

Ren, X.; Li, H.; Chen, J.; Wei, L.; Modak, A.; Yang, H.; Yang, Q. N-doped porous carbons with exceptionally high CO2 selectivity for CO2 capture. Carbon 2017, 114, 473–481.

Lin, Y.; Xiong, K.; Lu, Z.; Liu, S.; Zhang, Z.; Lu, Y.; Fu, R.; Wu, D. Functional nanonetwork-structured polymers and carbons with silver nanoparticle yolks for antibacterial application. Chem. Commun. 2017, 53(70), 9777–9780.

Li, G.; Zhang, B.; Wang, Z. Facile synthesis of fluorinated microporous polyaminals for adsorption of carbon dioxide and selectivities over nitrogen and methane. Macromolecules 2016, 49(7), 2575–2581.

Wang, Z. G.; Liu, X.; Wang, D.; Jin, J. Troger’s base-based copolymers with intrinsic microporosity for CO2 separation and effect of Troger’s base on separation performance. Polym. Chem. 2014, 5(8), 2793–2800.

Yang, X.; Yao, S.; Yu, M.; Jiang, J. X. Synthesis and gas adsorption properties of tetra-armed microporous organic polymer networks based on triphenylamine. Macromol. Rapid Commun. 2014, 35(8), 834–839.

Zhu, Y.; Long, H.; Zhang, W. Imine-linked porous polymer frameworks with high small gas (H2, CO2, CH4, C2H2) uptake and CO2/N2 selectivity. Chem. Mater. 2013, 25(9), 1630–1635.

Ashourirad, B.; Arab, P.; Verlander, A.; El-Kaderi, H. M. From azo-linked polymers to microporous heteroatom-doped carbons: tailored chemical and textural properties for gas separation. ACS Appl. Mater. Interfaces 2016, 8(13), 8491–8501.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51373143 and 21674087) and the Natural Science Foundation of Fujian Province (No. 2014J07002).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Tian, K., Zhu, TT., Lan, P. et al. Massive Preparation of Coumarone-indene Resin-based Hyper-crosslinked Polymers for Gas Adsorption. Chin J Polym Sci 36, 1168–1174 (2018). https://doi.org/10.1007/s10118-018-2127-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-018-2127-6