Abstract

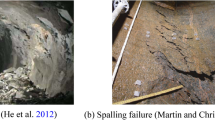

Spalling (Slabbing) is a typical failure phenomenon, which often occurs after excavation of rectangular tunnel. It has a serious impact on the construction, support and stability of the tunnel. To investigate the characteristics and mechanism of spalling-failure in rectangular tunnel, a series of tests were carried out on granite rectangular tunnel with different height-to-width ratios (H/Ws) (1/2, 3/4, 1/1, 4/3 and 2/1) by using true triaxial system. The whole process of spalling was monitored and recorded by wireless micro camera. According to the test results, the failure mode and failure characteristics of the sidewall spalling were summarized, and the influence of the H/Ws of the rectangular hole on the failure characteristics and stability of the tunnel were discussed in detail. The test results indicate that when the vertical principal stress is the maximum principal stress, the sidewalls of the specimens experience spalling failure. When the spalling occurs, the crack occurs at the shoulder corner of the sidewall and propagates along the axis, resulting in the spalling damage gradually developing from the local area to the whole sidewall along the axis, and forming the thin rock slab parallel to the sidewall. In addition, rectangular tunnels with different H/Ws clearly influence spalling failure. When the height was the same, the degree of spalling damage decreases with the decrease of its width. On the contrary, when the width was the same, the degree of spalling damage does not decrease with the increase in the height. When the height was equal to the width, the damage degree of the tunnel spalling is the largest, which seriously affects the safety of the tunnel. In the case of the same cross-section area of the tunnel, the stability of the tunnel can be improved by selecting the layout mode with the height greater than the width. It is necessary to strengthen the monitoring of the cracks at the shoulder corner of the tunnel, which can reduce the safety risk of the tunnel. These conclusions are helpful to the design of the tunnel, the prevention of spalling and the improvement of the stability of the tunnel.

Similar content being viewed by others

References

Cai M, Kaiser PK (2018) Rockburst support reference book-volume I: Rockburst phenomenon and support characteristics. Mining Innovation, Laurentian University, Sudbury, Ontario

Carter BJ (1992) Size and stress gradients effects on fracture around cavities. Rock Mech Rock Eng 25(3):167–186

Cristescu ND, Paraschiv I (1995) The optimal shape of rectangular-like caverns. Int J Rock Mech Min Sci Geomech Abstr 32(4):285–300

Du K, Tao M, Li XB, Zhou J (2016) Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance. Rock Mech Rock Eng 49(9):3437–3453

Du K, Su R, Tao M, Yang CZ, Momen A, Wang SF (2019) Specimen shape and cross-section effects on the mechanical properties of rocks under uniaxial compressive stress. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-019-01518-x

Exadaktylos GE, Tsoutrelis CE (1995) Pillar failure by axial splitting in brittle rocks. Int J Rock Mech Min Sci Geomech Abstr 32(6):551–562

Gong QM, Yin LJ, Wu SY, Zhao J, Ting Y (2012) Rock burst and slabbing failure and its influence on tbm excavation at headrace tunnels in Jinping II hydropower station. Eng Geol 124:98–108

Gong FQ, Luo Y, Li XB, Si XF, Tao M (2018a) Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels. Tunn Undergr Space Technol 81:413–427

Gong FQ, Si XF, Li XB, Wang SY (2018b) Experimental investigation of strain rockburst in circular caverns under deep three-dimensional high stress conditions. Rock Mech Rock Eng 52(5):1459–1474

Gong FQ, Wu WX, Li TB, Si XF (2019a) Simulation experimental study on spalling failure of surrounding rock in rectangular tunnel of deep hard rock. Rock Soil Mech 40(06):2085–2097 (in Chinese)

Gong FQ, Wu C, Luo S, Yan JY (2019b) Load–unload response ratio characteristics of rock materials and their application in prediction of rockburst proneness. Bull Eng Geol Environ 78(7):5445–5466

Gong FQ, Yan JY, Li XB, Luo S (2019c) A peak-strength strain energy storage index for rock burst proneness of rock materials. Int J Rock Mech Min Sci 117:76–89

He MC, Miao JL, Feng JL (2010) Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int J Rock Mech Min Sci 47(2):286–298

He MC, Xia HM, Jia XN, Gong WL, Zhao F, Liang KY (2012) Studies on classification, criteria and control of rockbursts. J Rock Mech Geotech Eng 4(2):97–114

He MC, Liu DQ, Gong WL, Wang CC, Kong J, Du S, Zhang S (2014) Development of a testing system for impact rockbursts. Chin J Rock Mech Eng 39(9):1729–1739 (in Chinese)

Hoek E (1965) Rock fracture under static stress conditions. CSIR report MEG 383. National Mechanical Engineering Research Institute, Council for Scientific and Industrial Research, Pretoria

Hoek E, Brown ET (2018) The Hoeke-Brown failure criterion and GSI - 2018 edition. J Rock Mech Geotech Eng 11 (3), 445–463

Hoek E, Kaiser PK, Bawden WF (1995) Support of underground excavations in hard rock. A.A. Balkema, Rotterdam, pp. 122–123

Hou ZS, Gong QM, Jiao WG, Sun ZH (2013) Demonstration of concave deformation of arc-shaped rock slabs in deep circular tunnels. Chi J Rock Mech Geo Eng 35(3):551–558 (in Chinese)

Jiang Q, Feng XT, Fan YL, Fan QX, Liu GF, Pei SF (2017) In situ experimental investigation of basalt spalling in a large underground powerhouse cavern. Tunn Undergr Space Technol 68:82–94

Li SJ, Feng XT, Li ZH, Zhang CQ, Chen BR (2012) Evolution of fractures in the excavation damaged zone of a deeply buried tunnel during TBM construction. Int J Rock Mech Min Sci 55:125–138

Li XB, Feng F, Li DY, Du K, Ranjith PG, Rostami J (2018a) Failure characteristics of granite influenced by specimen height-to-width ratios and intermediate principal stress under true-triaxial unloading conditions. Rock Mech Rock Eng 51(3):1–25

Li XJ, He MC, Sun YB, Zhou RX, Wang L (2018b) Study on the splitting failure of the surrounding rock of underground caverns. Geomech Eng 14(5):10–27

Liang CY, Zhang QB, Li X, Xin P (2016) The effect of specimen shape and strain rate on uniaxial compressive behavior of rock material. Bull Eng Geol Environ 75(4):1669–1681

Martin CD (1993) Strength of massive Lac du Bonnet granite around underground openings. Ph.D. thesis, Department of Civil and Geological Engineering, University of Manitoba, Winnipeg, Man

Martin CD (1997) Seventeenth Canadian geotechnical colloquium: the effect of cohesion loss and stress path on brittle rock strength. Can Geotech J 34(5):698–725

Martin CD, Read RS, Martino JB (1997) Observations of brittle failure around a circular test tunnel. Int J Rock Mech Min Sci Geomech Abstr 34(7):1065–1073

Ren G, Smith JV, Tang JW, Xie YM (2005) Underground excavation shape optimization using an evolutionary procedure. Comput Geotech 32(2):122–132

Stacey TR (1981) A simple extension strain criterion for fracture of brittle rock. Int J Rock Mech Min Sci Geomech Abstr 18(6):469–474

Su GS, Jiang JQ, Feng XT, Jiang Q, Chen ZY, Mo JH (2019) Influence of loading rate on strainburst: an experimental study. Bull Eng Geol Environ 78(5):3559–3573

Tuncay E, Hasancebi N (2009) The effect of length to diameter ratio of test specimens on the uniaxial compressive strength of rock. Bull Eng Geol Environ 68(4):491–497

Xu NW, Li TB, Dai F, Zhang R, Tang CA, Tang XL (2016) Microseismic monitoring of strainburst activities in deep tunnels at the Jinping II hydropower station, China. Rock Mech Rock Eng 49(3):981–1000

Zhao F, He MC (2016) Size effects on granite behavior under unloading rockburst test. Bull Eng Geol Environ 76(3):1183–1197

Zhou H, Lu JJ, Hu SC, Zhang CQ, Xu RC, Meng FZ (2016) Influence of curvature radius of tunnels excavation section on slabbing of hard brittle rockmass under high stress. Rock Soil Mech 31(1):140–146 (in Chinese)

Zhu WS, Yang WM, Li XJ, Xiang L, Yu DJ (2014) Study on splitting failure in rock masses by simulation test, site monitoring and energy model. Tunn Undergr Space Technol 41:152–164

Acknowledgements

Many thanks to Jifu Gao, the general manager of JingCheng Geotechnical Service Company that locates in Liuyang City, Hunan Province of China, for his sincere help in processing rock specimens.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 41472269), the Opening Fund of State Key Laboratory of Geohazard Prevention and Geoenvironment Protection (Chengdu University of Technology) (Grant No. SKLGP2018K010), and the Fundamental Research Funds for the Central Universities of Central South University (Grant No. 2019zzts673).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, Fq., Wu, Wx. & Li, Tb. Simulation test of spalling failure of surrounding rock in rectangular tunnels with different height-to-width ratios. Bull Eng Geol Environ 79, 3207–3219 (2020). https://doi.org/10.1007/s10064-020-01734-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-01734-w